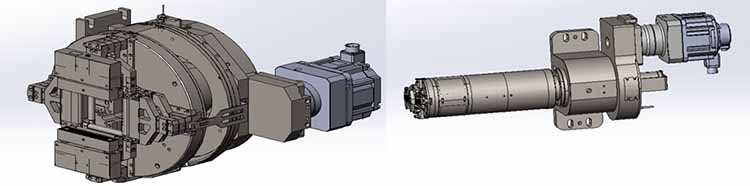

Two Chuck Zero Tail Professional Tube Laser Cutting Machine

The 2 chucks zero tailing laser tube cutting machine is designed for precise and efficient tube cutting. It features a unique zero-tail design, minimizing material waste while enhancing cutting accuracy. With 3000W laser power, this fiber laser metal pipe cutting machine is capable of precisely and efficiently cutting metal pipes up to 6500mm in length.

Equipped with an automatic loading and unloading system, it maximizes work efficiency and reduces labor costs. The dual chucks ensure stable and continuous tube rotation, enabling high-speed, high-precision cuts on a variety of tube sizes and shapes, including square, oval, round pipes, angle steel, channel steel, I-beams, and other irregular steel profiles.

- Dual Pneumatic Chuck Clamping System: Both front and rear chucks feature pneumatic clamping, with the rear chuck incorporating a blowing device to remove debris from the pipe wall during cutting. The clamping force is adjustable to accommodate different pipe sizes and loads, preventing deformation of thin-walled pipes while securely holding thicker pipes.

- Standard 0-Residue Cutting System: The front chuck and roller clamp enable zero-material-waste cutting, improving material utilization.

- Automated Feeding System: Compatible with semi-automatic or fully automatic feeding modules, saving labor costs, reducing operator workload, and enhancing production efficiency.

- Simple Operation and Remote Control: Easy to operate with wireless handheld remote control for cutting, drilling, moving, calibration, and emergency stops. The wireless handle also allows for pressure adjustment, ensuring fully automated production.

|

Laser: MAX

|

Autofocus Laser Cutting Head: WSX

|

|

|

Laser Chiller

|

|

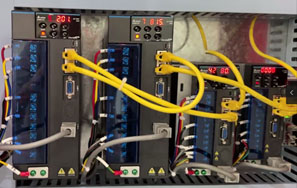

Servo Motors Adopting Delta’s bus control method ensures the realization of precise positioning and dynamic response with optimal acceleration, which makes the automatic positioning mechanism run smoothly, reliably and maintenance-free; X,Y,Z axes are driven by high-power motors. |

|

|

Heavy-Duty Welded Machine Bed Designed for high-power laser cutting, this ultra-stable, thick-plate welded bed is constructed from high-quality steel, providing excellent resistance to deformation and ensuring precision. The efficient cooling and dust-removal system further extends the machine’s lifespan. |

Chuck

| Front Clamp | RKQ-130 F | Back Clamp | RKH120 |

| Single Claw Stroke | 60mm | Single Claw Stroke | 30mm |

| Single Claw Thrust | 60kg.f | Single Claw Thrust | 50kg.f |

| Clamping Range | 10-120mm | Clamping Range | 10-120mm |

| Rated Speed (r/min) | 200 | Rated Speed (r/min) | 200 |

Application

The G Series Fiber tube laser cutter is suitable for cutting various metals, including stainless steel, mild steel, carbon steel, alloy steel, spring steel, iron, galvanized iron, aluminum, copper, brass, bronze, titanium, and more, in both plate and pipe forms. It is widely used in industries such as steel structures, automotive manufacturing, machinery production, furniture manufacturing, and metal processing. The cutting thickness varies depending on the selected laser power, allowing for versatile processing capabilities.

Reviews

There are no reviews yet.