Laser Marking Machine for Glass, Silicon, Plastic & Ceramics

UV laser marking machine is a device that utilizes ultraviolet (UV) laser technology to create marks, patterns, or designs on various materials. UV lasers have a shorter wavelength, 355nm output wavelength reduces the thermal impact on the processed parts, vibrating mirror type high-precision marking head, marking effect is fine and repeatable processing, high-precision and detailed spot to ensure that the marking result is perfect, marking process is non-contact, permanent marking effect.

Precision Engraving:

Equipped with a UV laser, this engraving machine boasts a short wavelength and a fine focusing spot. This unique combination allows it to achieve ultra-fine engraving, creating intricate designs, patterns, and text with exceptional detail and clarity.

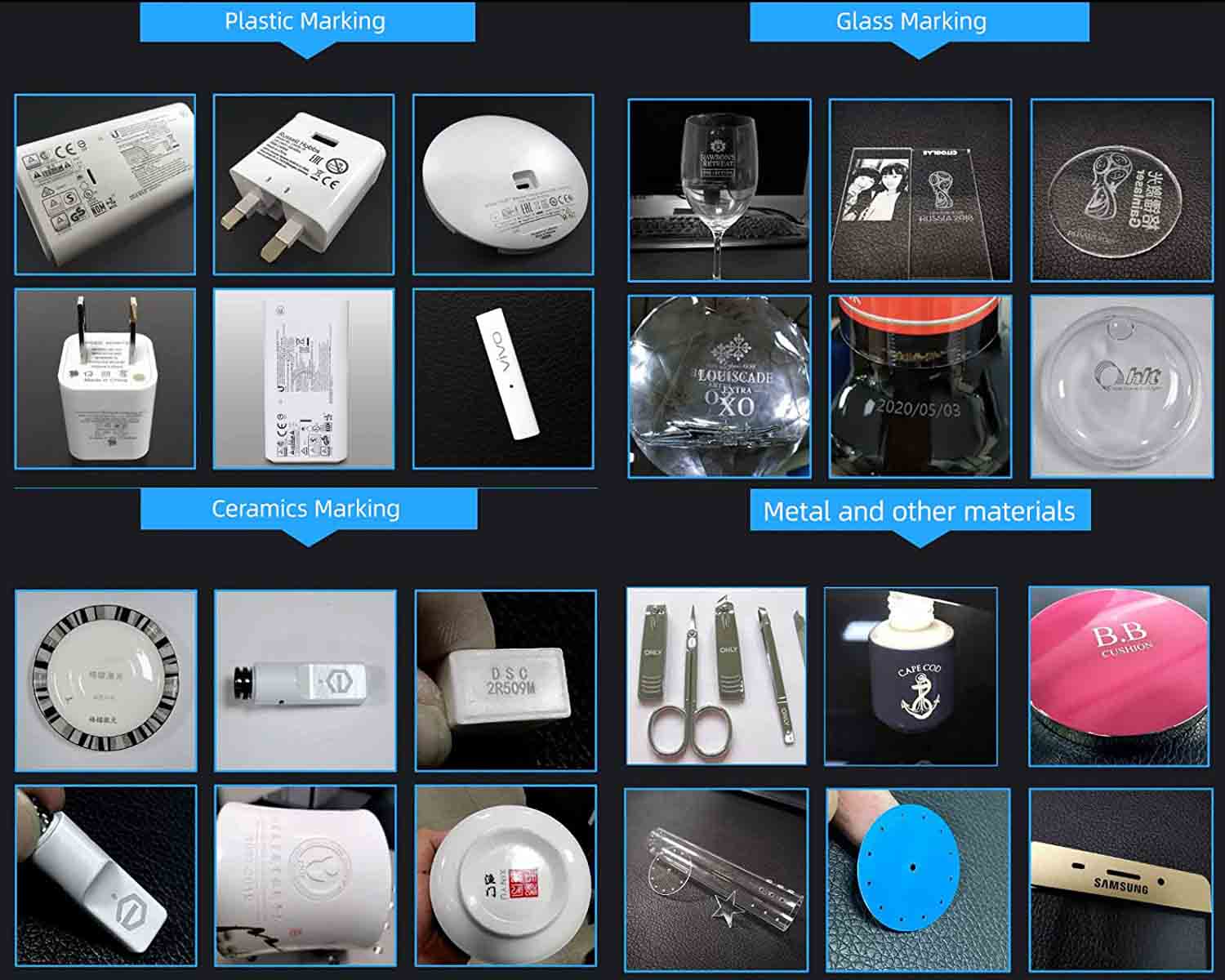

Material Versatility:

One of the standout features of desktop UV laser marking machine is its ability to work on a wide range of materials. From plastics to nylon, glass, and even wood, this machine can effectively mark and engrave on various surfaces, making it a versatile solution for different industries.

Minimal Heat Affected Zone:

The UV laser’s precision extends to minimizing the heat affected zone during engraving. This means that the surrounding material remains largely unaffected by the engraving process, preventing distortion, warping, or other forms of damage.

Enhanced Marking Speed and Efficiency:

The machine incorporates a high-speed digital galvanometer, resulting in swift and efficient marking. This aspect is particularly important for industrial applications where productivity is paramount.

2D Workstation Optional:

The 2D worktable ensures that the object to be marked is marked in the correct position. By adjusting the position of the table, the laser can be focused precisely on the specific location to be marked, thus ensuring accurate and consistent marking.

Wide Range of Applications:

The UV laser engraver finds its utility in various industries. It can mark expiration dates and batch numbers on plastic and glass packaging in the food and pharmaceutical sectors, engrave serial numbers on electronic components, embellish wooden products with intricate designs, and even add ornate patterns to glass surfaces.

Features

- UV lasers have a clean wavelength and a small focused spot, which facilitates complex and fine marking requirements.

- The heat-affected area is small, preventing damage to the target material.

- It is suitable for a wide range of materials, compensating for the limitations of infrared laser processing.

- High-speed digital galvanometer with significantly higher marking speed ensures higher efficiency and precision.

- No consumables, cost-effective to use and maintain.

- The system has stable performance and is suitable for heavy-duty marking tasks.

Application

UV laser marking system finds application in ultra-fine processing, packaging bottles for cosmetics, pharmaceuticals, and food products made from polymer materials. Additionally, it is utilized for tasks such as marking and dicing flexible PCB boards, performing micro-hole and blind hole processing on silicon wafers, marking QR codes on LCD liquid crystal glass, engraving on glassware, removing surface plating from metal.

⊙ Suitable for marking the surface of glass, polymer materials and other objects, micro-hole processing.

⊙ Widely used for marking the surface of packaging bottles (boxes) of polymer materials such as food, medicine, cosmetics, electric wires, etc., and punching micro holes (aperture d≤10μm).

⊙ Flexible PCB board, LCD, TFT marking, scribing and cutting.

⊙ Metal or non-metal plating removal

⊙ Silicon wafer microvia, blind hole processing.

What Materials Can Be Marked

PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, Silicon, Wood, Leather, Acrylic, Fabric, Surface of Plated Film, Glass, and Ceramics.

It is more suitable for the processing of materials with high reaction to heat radiation. It can cooperate with the production line, automatic loading and unloading, automatic feeding and unloading, and it is suitable for marking on the majority of metal and non-metal materials.

Reviews

There are no reviews yet.