Sheet Metal Fiber Laser Cutting Machine

The CNC Sheet Metal Laser Cutter CS Series is a high-performance, precision laser cutting machine designed for efficient cutting of metal sheets. This series utilizes the most advanced laser technology and CNC control systems, enabling high-speed and high-precision cutting operations, making it suitable for processing a variety of metal materials such as stainless steel, carbon steel, aluminum alloys, and more.

The laser cutter features a high degree of automation and ease of operation, equipped with an advanced laser generator that delivers stable laser output and excellent cutting quality. The machine is also fitted with a high-speed, high-precision motion control system, ensuring cutting accuracy and smooth edges during the process. Its powerful processing capability and flexible configurations make it widely used in industries such as machinery manufacturing, automotive, home appliances, advertising signage, and more.

Sheet Metal Laser Cutting Machine for High Efficiency & Precision Cutting

1. CNC Control System

Advanced CNC systems and laser cutting software enable precise control over the laser head’s movement, ensuring accuracy in complex patterns and reducing material waste.

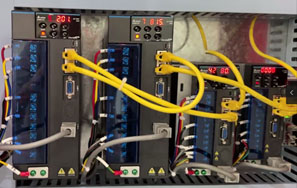

2. Servo Motors and Ball Screw Drive

Equipped with high-performance servo motors and ball screw drives, these systems deliver cutting accuracy up to 0.02 mm, ensuring repeatability and stable operation.

3. Lubrication Systems:

Integrated lubrication for linear guide rails maintains smooth motion and reduces wear, supporting the machine’s long-term high precision.

4. Water Chiller:

A water cooling system stabilizes the laser’s operating temperature, enhancing its reliability and cutting performance.

5. Small Laser Spot Size

Fiber lasers with a spot size significantly smaller than 10.6 μm CO2 lasers provide sharper cuts, improved precision, and finer details.

6. Flexible Bed Design

Options for fully enclosed or open-frame bed designs meet diverse operational needs, offering enhanced safety or easier accessibility depending on the application.

|

|

In addition, the CS series offers the following advantages:

- High-Performance Cutting: High-speed, high-precision cutting that increases cutting speeds by over 50% compared to traditional machines.

- Automated System: Smart operation interface simplifies workflows, reduces manual intervention, and lowers production costs.

- Strong Stability: Equipped with high-quality lasers and precision mechanical structures, providing stable cutting performance and long-lasting durability.

Laser Source

|

WSX Laser Cutting Head

|

Auto Focus Laser Cutting Head

WSX Laser Cutting Head

|

|

| Maximum Atmospheric Pressure | 25 Bar | Horizontal Focus Range | ±1.5mm | Effective aperture | 25 mm |

| Collimated focal length | F75-F100 | Vertical Focus Range | ±8mm | Weight | 5.5kg |

| Focusing focal length | F125/F150/F190 | Applicable power | ≤3000W |

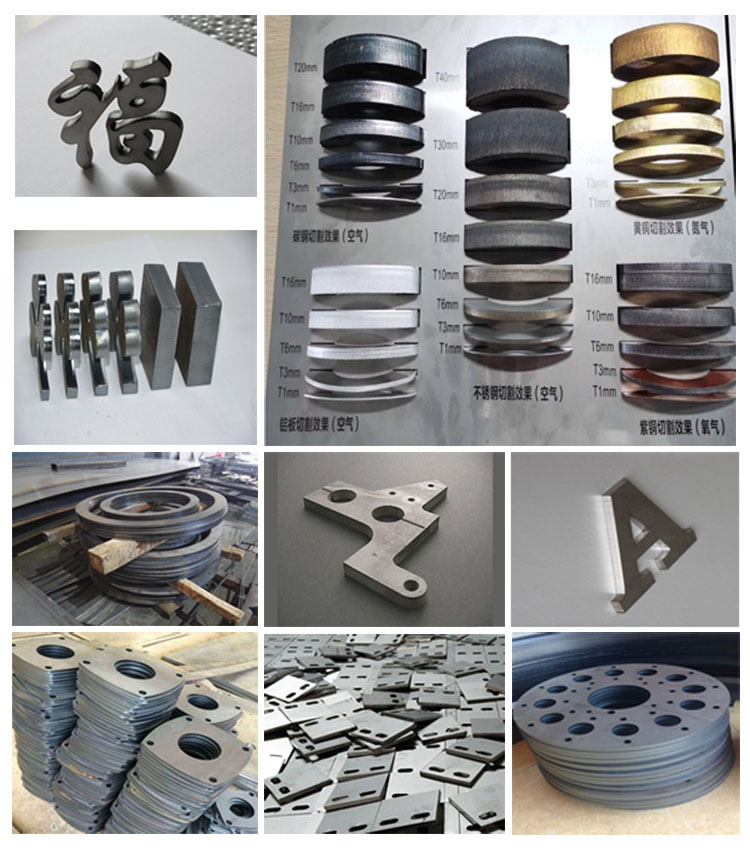

Application

Laser cutting machines can quickly cut alloys, carbon steel, stainless steel, copper, aluminum, gold, silver, and titanium, making them ideal for diverse industries. They are frequently employed in manufacturing billboards, electrical enclosures, fences, doors, windows, and building materials. Additionally, their precision and efficiency make them indispensable for producing automotive panels and components, ensuring high-quality results across various applications.

Why Choose Laser Cutter for Metal Sheet?

- The laser cutting machine features narrow cutting seams, minimal deformation, high precision, fast speed, and high efficiency.

- With high laser energy conversion efficiency, the thermal energy is concentrated in a very small area, allowing laser cutting to offer: narrow edge cuts, minimal heat-affected zones, and minimal local deformation.

- As a non-contact cutting method, the laser beam exerts no physical force on the workpiece, with no consumables required. The cutting ability is not affected by the material’s hardness.

- The laser beam is highly controllable, offering excellent adaptability and flexibility, making it easy to automate the cutting process.

Reviews

There are no reviews yet.