Portable Handheld Laser Cleaning Machine for Rust Paint Oil Dirt Stains Coating Removal

Pulse fiber laser cleaning machine consists of a pulse fiber laser source, a handheld laser cleaning gun, and user-friendly laser control system. Pulsed laser cleaning works by leveraging the difference in how the base material and surface contaminants absorb laser energy. For instance, in rust removal from cast iron, the rust has significantly lower melting and vaporization points compared to the metal. Pulse laser cleaning uses short, high-energy pulses that are readily absorbed by the contaminants, causing them to heat up rapidly, expand, and break away from the surface. This non-contact process effectively removes rust, paint, or other residues without damaging the underlying material.

Features of Handheld Laser Cleaner

- Non-Contact Cleaning

Safely removes contaminants without physical contact, preventing surface damage. - High Efficiency

Rapidly cleans surfaces, reducing downtime and increasing productivity. - Precision & Control

Targets specific areas with accuracy, preserving delicate surfaces. - No Consumables Required

Eliminates the need for chemicals or abrasive materials, reducing operational costs. - Environmentally Friendly

Dry process without chemicals, minimizing environmental impact and health risks. - Cost-Effective

Saves on labor, materials, and disposal, offering long-term cost savings. - Conservation of Original Surface

Gently cleans without altering the substrate, preserving its integrity and appearance. - Versatility

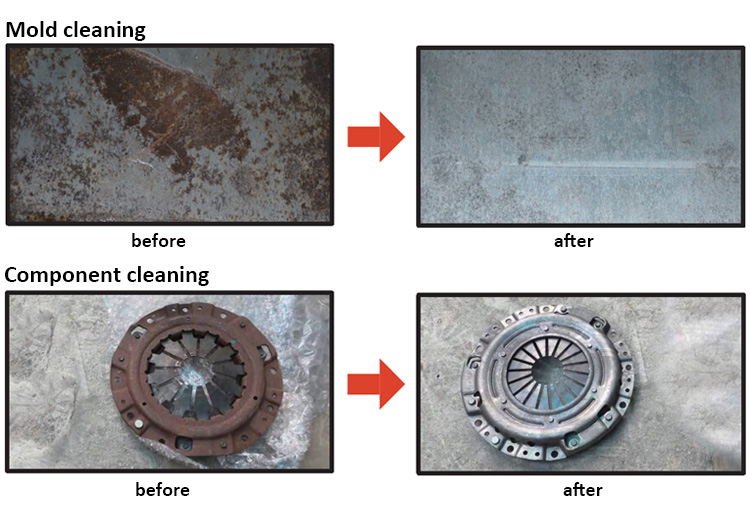

Handheld fiber laser cleaner can clean the resin of subject surface, oil stains, dirt, rust, coating, paint. Application to multiple scenarios, such as mold cleaning, paint stripping or coating removal, pre-treatment of parts before spraying, machine component cleaning, oxides removal before and after treatment of welding,etc

Features of Laser Cleaning Head

To ensure the handheld laser cleaning gun head remains compact, the design separates the galvanometer motor from the driver, minimizing the motor’s structural footprint. Two motors are housed within the handheld cleaning head, with the driver board installed inside the casing. The motor cable length is customizable, with a standard length of 6.5 meters. The modular design incorporates plug-and-play connectors for easy assembly and replacement. High-speed galvanometers are employed, capable of sustaining continuous operation at speeds up to 15m/s.

Field Lens Selection: Focus lens parameter selection, optional display 160mm focal length, 254mm focal length, 330mm focal length.

Galvo Speed: Adjustment of the reflection len swing speed, X reflection len fastest at 50Hz, increasing by 50/30 in each level.

Y reflection len fastest at 200Hz, increasing by 200/30 in each level. Range: 0~20m/s.

Laser Frequency: Laser pulse frequency, selectable from 1K~10000KHz.

Laser Power: Adjust laser output power, adjustable within the range of 1~100.

Laser Pulse Width: Used when using modulated pulse width lasers. Adjustable within the range of 1~2000.

Graphic Length: Length of the laser cleaning scan. Maximum length is 120mm, and the graphic length can be adjusted freely within this range.

Graphic Width: Maximum width is 120mm, and the graphic width can be adjusted freely within this range.

Fill Spacing: The density of the laser inside the graphic, ranging from 0-50, where smaller values result in denser filling.

Outer Circle Diameter: The maximum outer diameter of the graphic’s outer circle is 100mm. You can freely adjust the radius within this range to change the circular size. If using a square field mirror, it is recommended to have an outer circle diameter of less than 10mm.

Inner Circle Radius: For ring-shaped graphics, the maximum inner circle radius can be set to 100mm (but cannot be larger than the outer circle radius). You can freely adjust the radius within this range to change the size of the ring.

| Handheld Laser Cleaning Head

Portable laser cleaning guns are user-friendly with adjustable cleaning modes that provide the convenience of remote operation for increased efficiency. Capable of selective cleaning of specific areas with high precision and accuracy. The handheld design allows for easy movement and access to different areas for cleaning. |

|

|

Control Panel Display

The visualization interface is user friendly, simple to use, easy to use and highly efficient in cleaning. With adjustable cleaning modes, the laser parameters are adjusted according to the needs of the cleaning application. |

| Multiple Cleaning Modes Featuring pulse laser technology and a lightweight dual-pendulum cleaning head, the pulsed fiber laser cleaning machine has a variety of customisable modes that can be easily adapted to different tasks, making it easy to meet all your cleaning needs. |

|

|

Water Cooling System Adopt constant temperature, constant flow and constant pressure cooling system to prevent overheating and ensure the stability of high power handheld laser cleaner. |

Applications of Handheld Fiber Laser Cleaning Machine

The portable fiber laser cleaning machines is easy to set up and use. The operation is simple, turn on the machine to perform cleaning without chemicals, media, and water. It has the advantages of cost-effective, high-speed surface cleaning and excellent cleaning effect. It can remove resin, oil stains, stains, dirt, rust, coating, plating, and paint on the metal and non-metal surfaces.

Metal and Rust Removal: Laser cleaning machines can effectively remove rust, paint, and other coatings from metal surfaces. This is particularly useful in industries like automotive, shipbuilding, and construction where metal surfaces need to be cleaned and prepared for welding, painting, or other treatments.

Historical Restoration: These machines can be used to restore historical artifacts, sculptures, and architectural elements made of metal, stone, or wood without causing damage to the underlying material.

Graffiti and Coating Removal: Portable laser cleaners are used to remove graffiti from public spaces, bridges, and buildings without the need for abrasive chemicals or abrasive blasting, which can harm the environment.

Industrial Equipment Maintenance: In manufacturing and industrial settings, laser cleaning machines can be used to maintain machinery and equipment by removing grease, coatings, and contaminants from critical components.

Construction Industry: Laser cleaning can be used to clean concrete forms, remove old paint, and prepare surfaces for new construction or renovations.

Shipbuilding and Maritime: Shipbuilders use laser cleaning to remove rust, paint, and marine growth from ship hulls and other components, extending the life of the vessel and improving its fuel efficiency.

Automotive Industry: Laser cleaning is employed in the automotive industry for tasks such as removing paint, rust, and contaminants from vehicle bodies, engine parts, and other components.

Electronics Manufacturing: In electronics manufacturing, laser cleaning can be used to remove solder residue, flux, and contaminants from circuit boards and components, ensuring high-quality products.

Reviews

There are no reviews yet.