Mopa Fiber Laser Spot Welder for Metal

The MOPA fiber laser welding machine is a specialized tool tailored for precision welding tasks involving on flat metal surfaces. This welding machine utilizes MOPA (Master Oscillator Power Amplifier) fiber laser technology, offering advanced control and flexibility in the welding process. Specifically optimized for working with metal plane surfaces and copper materials, this equipment ensures reliable and high-quality welds. Its capabilities include precise control over the welding parameters, making it suitable for applications where accuracy and performance are crucial, especially in the context of copper nipple welding on flat metal surfaces.

MOPA laser welder adopts mopa fiber laser source, its pulse frequency and pulse width are independently controllable, through the adjustment of the two laser parameters, a constant peak power output can be achieved, so the range of applicable materials is wider.

Optional: two-axis or three-axis galvanometer fiber laser welding machine

Laser Welding Head

The MOPA fiber laser welding head is specially optimized for specific industrial environments, ensuring reliable and stable operation over extended periods. It utilizes ultra-precision drive motors to control mirrors, delivering excellent welding quality and speed. Seamless integration with the system enhances production efficiency, and modular component design facilitates rapid on-site equipment maintenance, allowing customers to quickly restore capacity for uninterrupted 24-hour production.

Characteristics:

1. This welding head is suitable for 200W and below power band.

2. The internal structure of the laser head is completely sealed, which can avoid contamination of the optical lens.

3. The structure of the protective mirror adopts the drawer type, which is easy and simple to replace.

4. It can be used for all kinds of lasers with QBH fiber connector.

Application

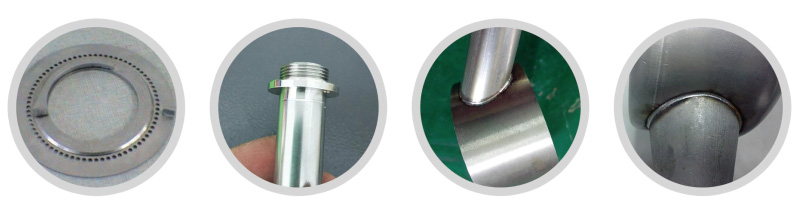

Galvanometer laser spot welding machine is a high-quality, high-precision, low-deformation, high-efficiency and high-speed application technology, it is widely used in metal material processing and manufacturing. This MOPA Laser Welder was applied to precision parts in 3C, mobile phone structure parts, electronic component, small motors, cylindrical batteries, etc.

Welding Materials

Stainless steel, aluminum alloy, copper, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, and so on.