Mini Air Cooled Handheld Laser Welding Machine

This air cooled handheld laser welder is compact, lightweight, and easy to use, making it ideal for metal applications and small spaces. The handheld air-cooled laser welding system excels in welding stainless steel, carbon steel, galvanized sheets, aluminum alloy, brass, and copper, delivering precise, spatter-free welds with high strength and minimal deformation. Its advanced laser control system ensures stable beams, consistent weld quality, smooth and flat joints, and eliminates the need for post-grinding, offering superior speed and efficiency.

Features of Air Cooled Handheld Laser Welding Machine

- Air-cooled handheld laser welder is a new type of welding method, mainly for welding of thin-walled materials and precision parts.

- It can realize spot welding, butt welding, stack welding, sealing welding and so on.

- High depth-to-width ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, flat and beautiful weld, no need to deal with after welding or just simple treatment.

- High quality of weld seam, can be precisely controlled, high positioning accuracy.

- Reliable: aviation grade air-cooled.

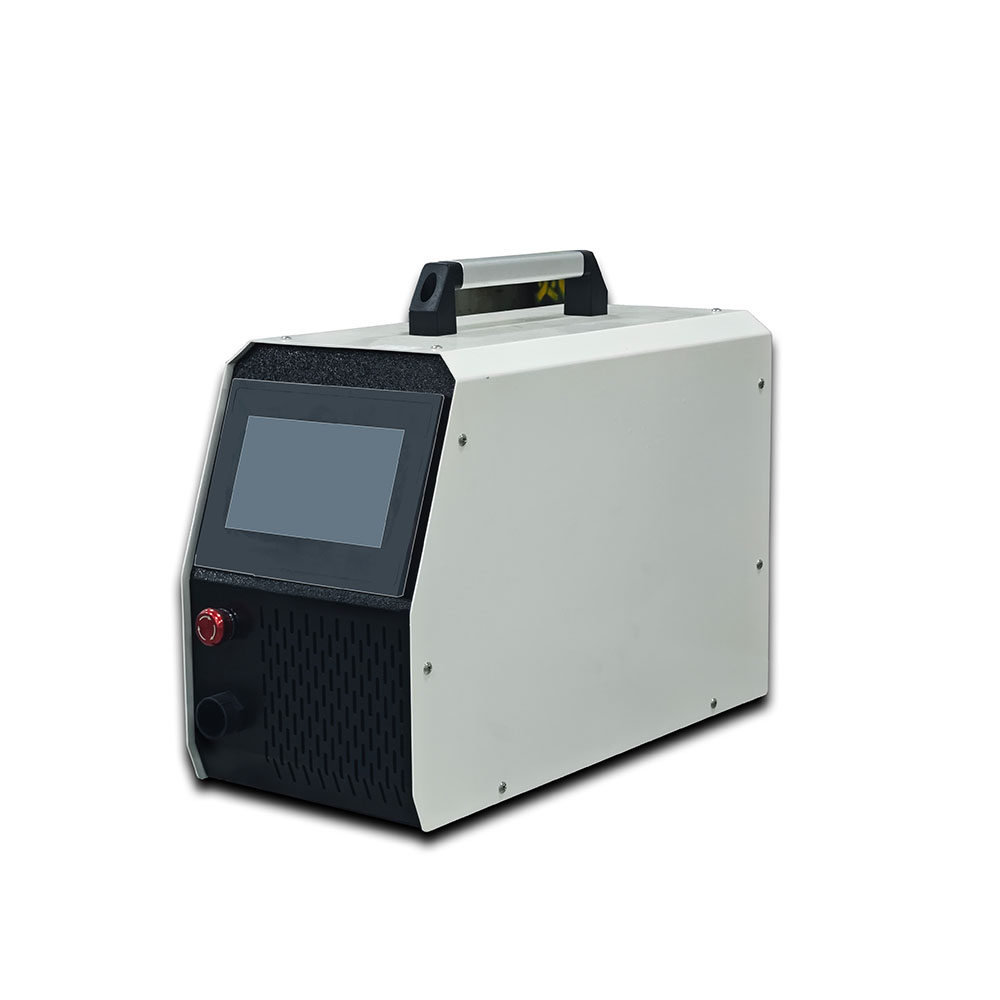

- Portable: weight ≤ 25 KG, volume ≤ 0.06 m³

- Stable: long time stable operation.

Various Metal Materials

|

|

|

|

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel |

laser welding copper |

Product Configuration

|

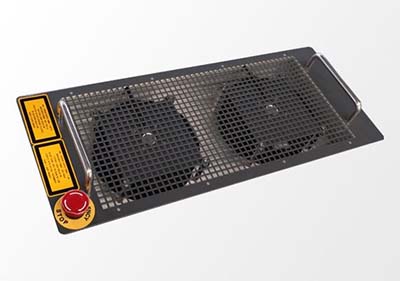

Air-cooling system:

Adopting efficient air-cooling technology, eliminating the traditional water-cooling system, the machine is more lightweight and compact, suitable for a variety of working environments. |

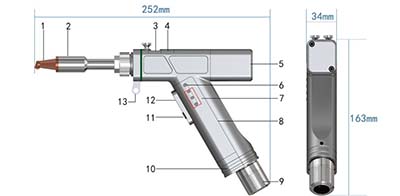

| Laser welding head:

The lightweight design of the laser welding head, weighing only 0.65kg, combines advanced optics and beam transmission technology. The welding head adopts a collimated laser beam of φ≤10mm to ensure stable beam transmission and high welding precision, providing a flexible and convenient operation experience. |

|

|

Laser source:

High-quality laser generator that can output a stable laser beam to ensure uniform and precise beam intensity during the welding process. The laser generator adopts advanced technology to provide powerful laser power, which can quickly realize precise welding results, applicable to a variety of metal materials to ensure the quality and strength of the weld. |

| Automatic wire feeder:

Integrated automatic wire feeding system that efficiently and accurately feeds the wire into the welding area, ensuring continuity and uniformity of the metal filler during the welding process. |

|

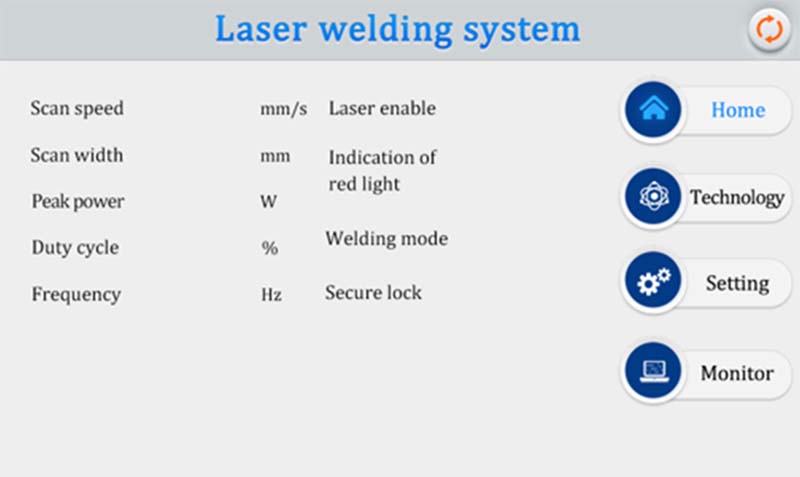

Laser welding system supports continuous welding, spot welding, automatic welding control, password authorization and other functions. Suitable for handheld laser welding systems and air-cooling systems, and supports 19 languages.

Application industries:

Compact air-cooled laser welding machine for metal manufacturing and processing industries, such as metal welding, surface welding of electrical switch cabinets, elevator manufacturing, household appliance manufacturing, stainless steel stove, frame, doors and windows, fence, electric box, pipeline, and kitchenware manufacturing. Welding of various metal materials such as carbon steel, aluminum alloy plate, galvanized plate, electrolytic plate, silicon steel, titanium alloy, galvanized aluminum plate, and copper.

Reviews

There are no reviews yet.