Metal Tubes CO2 Laser Cutting Machine

Metal tubes CO2 laser cutters utilize metal encapsulated CO2 lasers for greater durability and reliability, maintaining high gas purity and extending laser life. The all-metal sealed construction reduces gas leakage and improves energy conversion efficiency and stability for long, efficient and stable cutting operations. In contrast, glass tubes CO2 laser cutters use glass-encapsulated laser tubes, which may be cheaper to manufacture, but are fragile, less resistant to vibration, and suffer from rapid degradation of gas purity and short maintenance intervals.

Metal Laser Tubes:

- Longer service life: Metal encapsulated lasers typically promise a higher number of operating hours, reducing replacement frequency and maintenance costs.

- Good Stability: The metal tube design provides a more stable laser output, which is conducive to improved cutting quality and accuracy.

- Shock resistance: Metal is more resistant to mechanical stress and potential damage during daily operation.

After pattern designs are completed, the software auto-arranges them for tight fits to minimize material waste. An advanced transmission system allows the laser to cut in straight lines, instant speed shifts, and self-adjusting speeds, ensuring smooth edges and natural curves at corners. Linear motion guides ensure the laser head moves smoothly, rapidly, and vibration-free during operation.

This CNC CO2 laser cutting machine adopt imported proprietary sliding guide, and equip with auxiliary facilities, such as blower, exhaust fan, infrared, foot pedal and other auxiliary facilities. Also, this series products integrate advanced high-speed continuous curve motion control card, and adopt self-developed high-speed laser engraving & cutting controlling software.

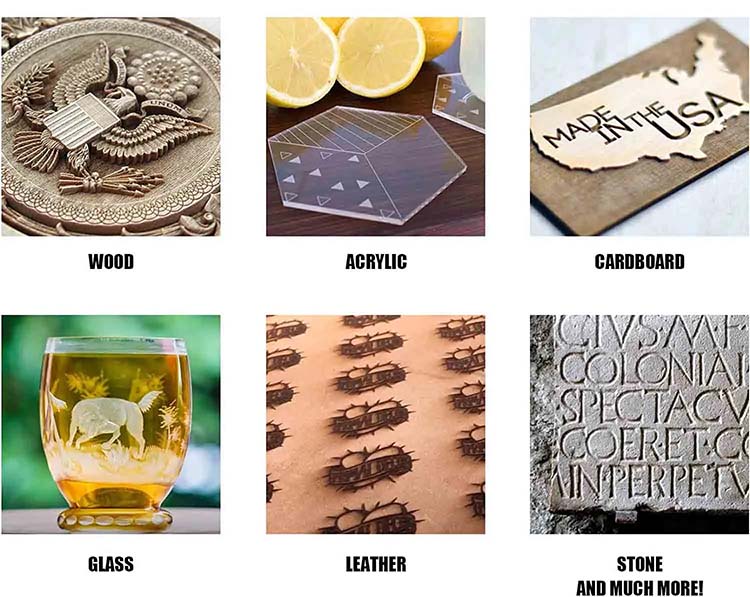

These CO2 laser cutters are widely used in various industries for cutting materials such as wood, acrylic, plastic, fabric, rubber, and thin metal sheets. They are especially popular in industries like signage making, textile garment manufacturing, and electronics.

Features:

- Motion control system: high-speed micro stepper motor

- Cutting fast, efficient and pollution-free

- Small laser pulse, easy to operate

- Low cost, no consumables

Paramenters:

What’s right for you depends on the largest size of your workpiece. We have standard work beds in a variety of sizes. Please choose from the specification table, please contact us if you need to customize.

Product Advantages:

- Easy to use

You can easily prepare your laser job on the full graphics display and graphically track your progress during the cutting or engraving process. The machine is easy to use for (non-technical) beginners and also suitable for advanced users. - Electric Working Bed

The CO2 laser machine comes standard with a motorized table height adjustment. This makes it possible to move the table up and down at the touch of a button. This allows you to quickly and easily raise or lower the work bed, switch between different materials and material thicknesses. - Auto Focus

CO2 laser cutters and engravers come standard with fully automatic focus. The laser head in perfect focus at the touch of a button after each material change.

What Materials can be Cut with CO2 Laser Cutting Machine?

Leather, plexiglass, acrylic, plastic, fiberboard, PVC, paper, wood, bamboo, ceramics, granite, etc.

From the Applicable Material table you can find the applicable material and the thickness, if you can’t find it in the table, please feel free to contact our experts for consultation.

Applicable Industry:

- Advertising industry: mainly used in large character cutting, color plate engraving and cutting, advertising materials, crystal characters, easel, packing boxes;

- Shoe Material Processing: Used for precise cutting of shoe upper materials, intricate hollowed-out floral designs;

- Apparel Industry: Achieves fine cutting of patch embroidery, woven labels, logo trimming, as well as various artistic flower treatments for garment accessories; can also perform

- punching, edging, hole punching, and initial sample making work;

- Leather Manufacturing: Suitable for customized cutting and engraving of various leather materials;

- Non-Metal Material Processing: Efficient cutting of lightweight non-metal materials such as organic glass, plastic, paper, fiberboard, PVC, etc.;

- Wood and Bamboo Products Industry: Capable of fine carving and cutting of bamboo and wood products;

- Decoration and Crafts Production: Suitable for fine carving of hard materials such as ceramics, granite, as well as the creation of other wooden or stone artworks.

CO2 Laser Cutting and Engraving Machine Samples for Reference

If you want to know more about CO2 precision laser cutter. We are willing to show you more samples. Please feel free to tell us your material and pattern so you can see the cutting and engraving results of these CO2 laser machines immediately.