Cheap Handheld Fiber Laser Welding Machine

Hand held metal laser welding machine is smaller in size and more convenient to operate and carry. The handheld laser welding machine replaces the previous fixed working mode with a handheld welding gun and realize more welding possibilities.

Feature:

- This laser welding machine is designed with a compact body and a hand-held welding gun, which is easy to use and makes the welding more flexible.

- Automatic laser welding function, about 2~10 times faster than traditional welding.

- With a simple control system, this laser welding machine is easy to learn and easy to operate. Beginners can operate without a certificate.

- The finished weld is smooth and requires little polishing.

Application:

The laser welding machine is used to weld all kinds of metal materials. It can realize stainless steel, stainless steel, gold foil, precision stainless steel, aluminum, iron paint, etc. It is widely used in the complicated and irregular welding processes of cabinets and kitchens, hardware processing, auto parts, shelves, ovens, stainless steel doors and windows guardrails,distribution boxes, furniture, jewelry welding, metal sheet metal and other industries.

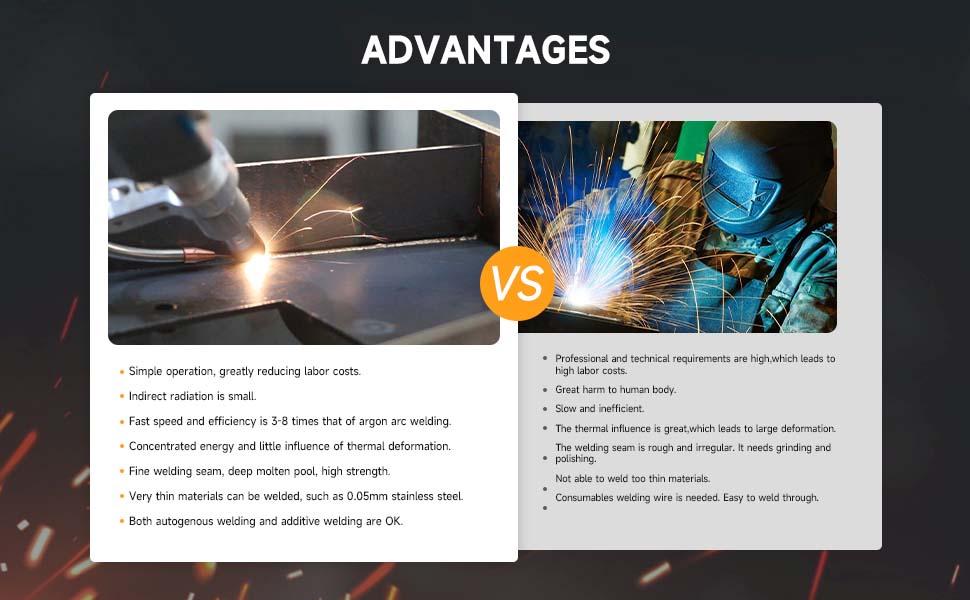

Why Choose Laser Welding Machine:

The fiber laser welding machine is ideal for working on metallic parts. Furthermore, it offers great reliability and efficiency. And the price of handheld laser welding machine has a high cost performance compared with other laser welding machines.

- Laser welding technology has multiple benefits over conventional types of welding technologies:

- The integration of laser welding is easier with automation and computer. The operation becomes more accurate and efficient.

- The final weld is of high quality and durable for a long time to come.

- The speed of the welding process is much higher than that of conventional welding techniques. This makes the laser welding technology suitable for batch productions.

- Laser welding is applicable to products that require a high level of accuracy.

- No secondary finishing of the product is necessary after welding

- Contactless welding. No contacting parts and thus the quality of the final product.