Laser Welding Machine with N₂ Generator

The laser welding machine with N₂ generator combines the precision of laser welding with the benefits of nitrogen gas shielding. By integrating a nitrogen generator, it ensures a clean and oxygen-free environment during welding, enhancing weld quality and efficiency.

Stable Performance Reliable Quality

The handheld laser welding machine utilizes world-class lasers from Chuangxin and Ruikai, ensuring precise laser control and stable beam quality. All our products comply with SGS industry standards, with a laser power supply lifespan of approximately 100,000 hours, guaranteeing durable and stable beam output.

Compact Handheld Welding Gun

Our welding guns feature ergonomic designs for ease of operation, providing users with comfort. We also offer built-in oscillation functionality and dual safety laser buttons, enabling operators to work safely around the clock while consistently delivering high-quality welding.

Compact and Portable

The compact design enhances portability, facilitating transportation and installation.

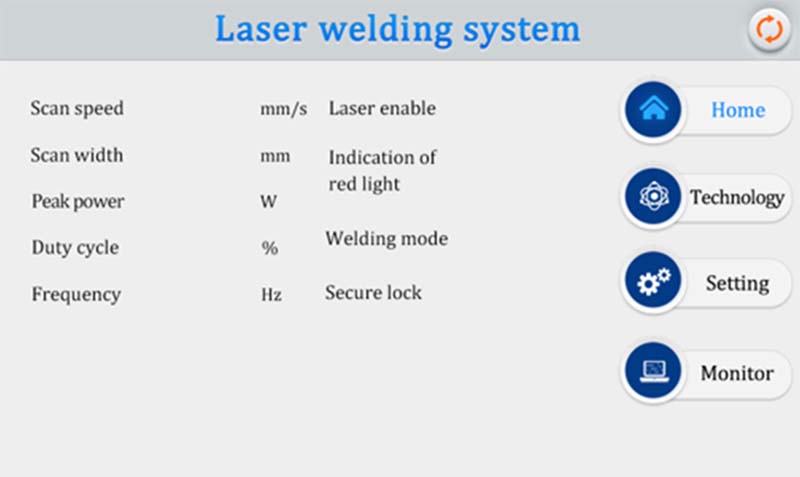

Simple Control System, Intelligent Welding Modes

Featuring an LED touchscreen and intelligent multilingual operating system, the operation is simple, user-friendly, and efficient. Even beginners can master welding operations with just 1-2 hours of training, significantly reducing training and production costs. The equipment comes pre-loaded with 32 sets of process parameters and allows user customization. This enables operators to quickly select welding parameters based on various materials and thicknesses, ensuring high-quality and consistent welds comparable to those produced by experienced welders.

Easy Installation and Operation

The product’s rear panel is labeled clearly, making setup easy, particularly for beginners. Our user guide videos further simplify installation. Anyone can undergo training and quickly achieve consistent, high-quality welding results across various materials and thicknesses.

Goodbye to Traditional Welding

Traditional welding techniques are complex, carried out in harsh working environments, and inefficient. They are unsuitable for special metals and thin plates, resulting in high wire consumption and requiring pre-cleaning and joint preparation to achieve full penetration welding. Welders need extensive welding experience to execute these techniques.

Features of Handheld Fiber Laser Welding & N₂ Generator Machine

Laser Source: The machine would have a high-quality fiber laser source for precise and focused energy for welding.

N₂ Generator: The N₂ generator produces high-purity nitrogen gas, which is used as an assist gas during the welding process. Nitrogen helps to shield the weld area from atmospheric gases, preventing oxidation and improving weld quality.

High Precision: Laser welding is known for its high precision and accuracy. Protected by 99.99% pure nitrogen, the machine achieves greater precision, produces clean and aesthetically pleasing weld seams, and minimizes the heat affected zone.

Widely Applications: These machines are often versatile and can be used for welding a wide range of materials, including metals like steel, aluminum, and titanium, as well as various alloys.

Automated Controls: Many modern laser welding machines come with user-friendly interfaces and automated controls, allowing operators to easily set welding parameters and monitor the process in real-time.

Energy Efficiency: Laser welding machines are generally energy-efficient compared to traditional welding methods, as they focus energy precisely on the weld area, minimizing heat dissipation and reducing energy consumption.

Maintenance: The 2 in1 integrated design is easy to maintain and use, with removable components and clear instructions for daily maintenance tasks.

Nitrogen Generator

Automatic emptying function

Full-automatic purity control, no gas supply when the purity is not up to standard, to ensure that the purity of the moment are up to the welding effect.

Stable nitrogen purity

The purity of welding nitrogen gas is constantly stabilized above 99.99%, and no gas will be supplied if the purity is not up to standard, so as to maintain stable welding effect.

Nitrogen purity visualization

Equipped with standard purity detector, real-time display of purity, reflecting the professional application of laser welding nitrogen generator.

Automatic start and stop

When the nitrogen pressure reaches 6kg, it will stop automatically. The setting of automatic start and stop is more humanized.

Various Metal Materials

|

|

|

|

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel |

laser welding copper |

Supports continuous welding, spot welding, automatic welding control, password authorization and other functions.

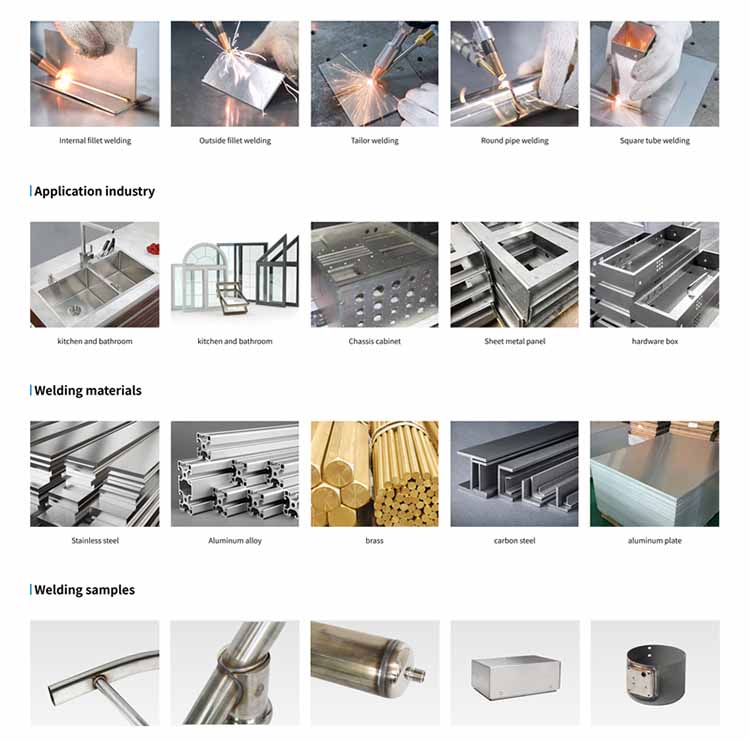

Application industries:

Handheld fiber laser welding machine for metal manufacturing and processing industries, such as metal welding, surface welding of electrical switch cabinets, elevator manufacturing, household appliance manufacturing, stainless steel stove, frame, doors and windows, fence, electric box, pipeline, and kitchenware manufacturing.

Welding of various metal materials such as carbon steel, aluminum alloy plate, galvanized plate, electrolytic plate, silicon steel, titanium alloy, galvanized aluminum plate, and copper. DPLASER welders deliver four times faster welding speeds, higher weld strength, and reduced porosity.

Reviews

There are no reviews yet.