Pulsed Laser Cleaning Machine for Metal Rust & Paint Removal

Pulsed handheld laser cleaning machine for metals effectively removes rust, paint, oil, dirt, and coatings without damaging the base material.

Handheld laser cleaning machine use digital control technology to precisely clean hard-to-reach areas, are environmentally friendly and do not use chemicals, making them a cost-effective and user-friendly solution for industrial cleaning. DPLASER offers a full range of powerful and precise laser cleaning systems from 1000W~3000W to meet all your application needs.

The chassis of the handheld laser cleaner is black and white, which is more high-end. The handle and universal wheel design make it more lightweight, durable and easy to move.

Advantages of Laser Cleaning Machines

Laser cleaning can solve problems that cannot be solved by traditional cleaning methods. It is especially effective for applications like paint removal, rust removal, metals and non-metals surface cleaning, all without damaging the substrate.

- Non-Contact Cleaning: Laser cleaning is completely non-contact, ensuring no abrasion or damage to the part’s substrate.

- High Efficiency: Laser beam delivers fast, effective cleaning—significantly reducing cleaning time and improving productivity.

- Precision and Selectivity: Allows for highly accurate, selective cleaning—targeting specific areas with precise control over position and size.

- Eco-Friendly and Chemical-Free: No need for chemical solvents or consumables, making it safer for operators and more sustainable for the environment.

- Easy Operation: The system supports both handheld use and seamless integration with robotic arms for automated cleaning. Features an integrated control system for intuitive operation and quick setup.

- Ergonomic and Integrated Design: Features an integrated control handle with button layout for ease of use during extended operation.

- Advanced Scanning System: Equipped with a built-in scanning module that uses compact, high-speed motors and precision drivers.

- Durable Construction: The main body is manufactured as a single solid unit—offering strong, stable, dustproof, and long-lasting performance.

| Handheld Laser Cleaning Head

Portable laser cleaning guns are user-friendly with adjustable cleaning modes that provide the convenience of remote operation for increased efficiency. Capable of selective cleaning of specific areas with high precision and accuracy. The handheld design allows for easy movement and access to different areas for cleaning. |

|

|

Control Panel Display

The visualization interface is user friendly, simple to use, easy to use and highly efficient in cleaning. With adjustable cleaning modes, the laser parameters are adjusted according to the needs of the cleaning application. |

| Multiple Cleaning Modes Featuring continuous laser technology and a lightweight dual-pendulum cleaning head, the continuous wave fiber laser cleaner has a variety of customisable modes that can be easily adapted to different tasks, making it easy to meet all your cleaning needs. |

|

|

Water Cooling System Adopt constant temperature, constant flow and constant pressure cooling system to prevent overheating and ensure the stability of high power handheld laser cleaner. |

Application of Fiber Laser Cleaning Machine

Handheld laser cleaning system for rust removal, oxides removal, cleaning of molds, equipment cleaning, paint stripping or coating removal, pre-treatment of parts before spraying, pre-treatment before welding, removal of old paint, cleaning of building exterior walls, cleaning in the electronics component, precise degreasing cleaning in the precision machinery industry, cleaning of pipes in nuclear power plant reactors.

Laser Rust Removal on Metals

Laser cleaning efficiently removes rust from metal surfaces, restoring their original luster without any physical contact.

Laser Paint Removal

Ideal for removing paint residues from metal and other surfaces, laser cleaning offers precise, fast operation while preserving the integrity of the base material. It is especially effective for intricate shapes and small components.

Laser Coating Removal

Laser technology enables accurate removal of coatings such as paint, spray layers, or protective films from metal, plastic, and other materials. It eliminates the need for physical contact or chemical solvents, protects the substrate, and enhances adhesion for subsequent coatings or treatments.

Laser Weld Cleaning

Laser cleaning quickly removes oxides, slag, and contaminants from weld zones, improving weld quality and ensuring the precision and strength of the joint.

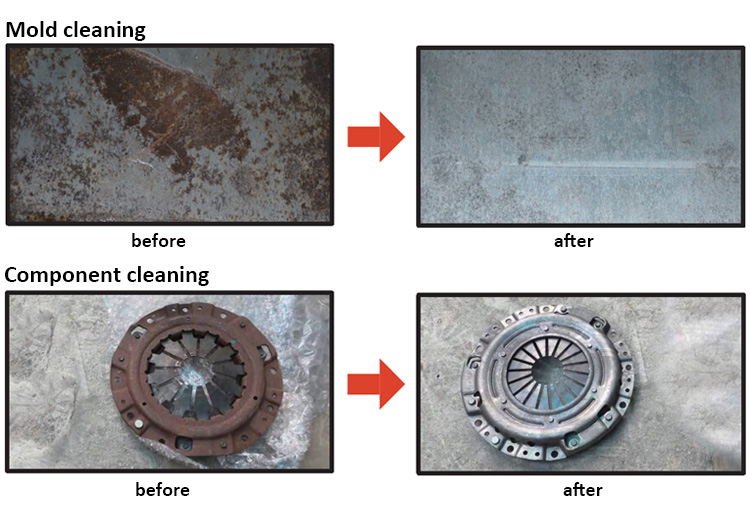

Cleaning of Machinery and Components

Laser cleaners effectively eliminate grease, metal shavings, rust, and other contaminants from mechanical equipment and components, helping to restore surface condition and maintain optimal performance.

Mold Cleaning (e.g., Tire, Rubber, Injection Molds)

Laser cleaning removes surface residues from molds quickly and thoroughly, restoring their original condition. The non-contact method avoids wear and tear typically caused by traditional cleaning techniques, thereby extending mold life.