CO2 UV Online Flying Fiber Laser Marking Machine for PE, Plastic, ABS, Rubber Metal Making

Online flying fiber laser marker is mainly used to spray and engrave the code on products surface of flowing production line. It is different with traditional laser marking machine which only can mark on static objects.

This laser marking machine on the flying adopts imported top brand fiber laser source , high-speed galvanometer scanning system, Japan electro-optical sensors, and professional on the fly marking control software, can increase production speed, reduce bad pieces, improve line safety, greatly improve efficiency and adapt to industrial production demand. It is no longer just marking production data and batch number, it also has anti-fake, anti-channel conflict feature because of its visual and tactile effects, also it never can be erased.

Features:

Laser Module: 30W/50W/100W laser power to meet your requirement, stable operation.

Field Lens: High end transmission field lens, small spot, high precision, fast speed, light transmittance above 99%.

Galvo-Tech Scanning: The Galvo-Tech drive and scanning system provides both outstanding accuracy and fast, stable marking of flat surfaces at speeds up to 275.6 inches per second.

Worktable: Standard positioning holes, multiple flexible screw holes on the worktable, convenient for custom installation of special fixture platform.

Advantages of Online Fiber Laser Marking Machine

1. Fast marking speed.

2. Power is controlled by software, continuously adjustable.

3. Carving effect is perfect, permanent identification.

4. Anti-counterfeiting code automatically generated.

5. No consumables, without wearing parts, maintenance-free, low operating cost.

6. Perfect dynamic and static marking on production line.

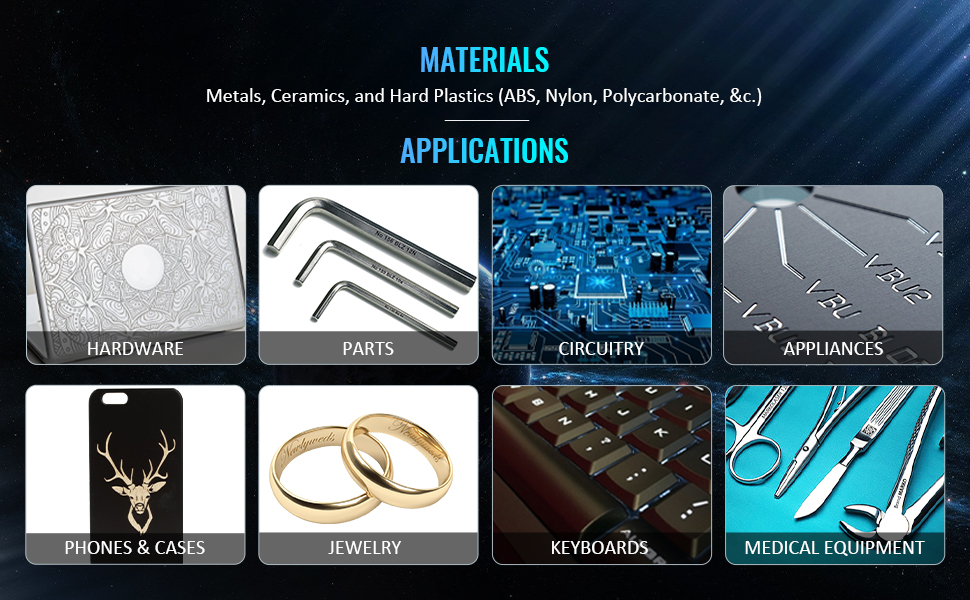

Online Fly Fiber Laser Marking Machine Applications

1. Metal & non-metal material and products: Stainless steel, gold, silver, copper, aluminium alloy, hardware, tools, acrylic, ceramics, plastics, organics, thermo-elastomer rubbers, paper and others

2. Jewelry customization

3. Electronic component: capacitor, inductor, PCB, IC, connector, control panel and other instruments

4. Others: Cosmetics, food package, bottle, gift, advertisement & sign crafts, craft & gift making

Applicable Material

Metal: stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminium plate, gold, silver, titanium, ring and other plate products.

Nonmetal: painting acrylic, density board, plastic, acrylic acid, rubber, bamboo, marble, painting glass, TPU, etc.