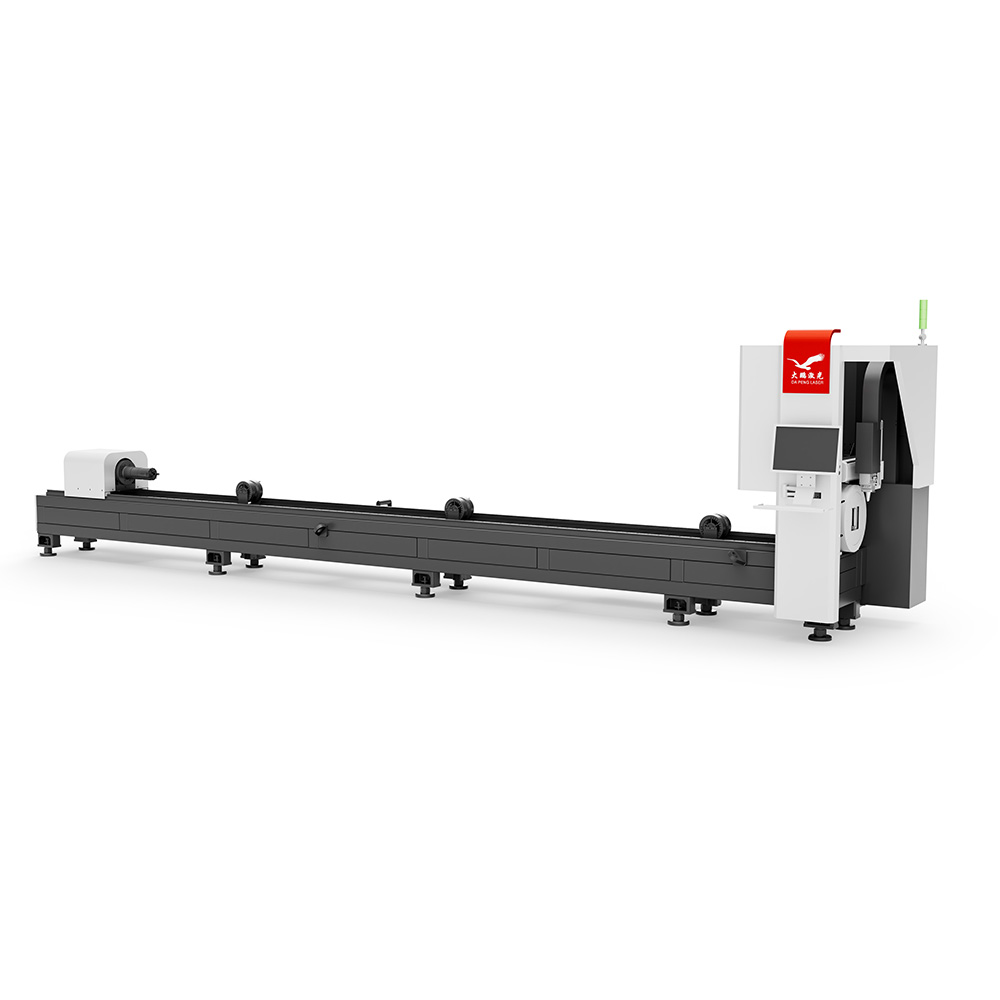

Industrial CNC Laser Cutting Machine for Metal Tube

Cost-effective tube fiber laser cutting machine for is an affordable, practical, and versatile tube laser cutter machine. The most productive laser solution for your metalworking. Square and round tube, range min. ∅10 – max.∅ 160mm.

Features

- Utilizing high-precision gears, racks, and linear guides imported for smooth transmission and high accuracy, the fiber laser tube cutting machine ensures stable operation and prolonged lifespan of transmission components through laser interferometry.

- Adopting a U-shaped beam structure, the bed features a welded construction with a combination of integral square tubes and plates. Subjected to 600°C high-temperature heat treatment and 24-hour furnace cooling, followed by rough processing, vibration aging treatment eliminates welding and processing stress. The 12-meter gantry is milled for semi-rough and fine processing, resulting in excellent rigidity, high accuracy, resistance to bending and twisting torque, and permanent deformation-free use. The Z-axis is constructed from integral cast aluminum, providing lightweight characteristics and rapid dynamic response, ideal for high-speed machining and acceleration.

- All axes (X, Y, Z, W1, W2) are equipped with domestically produced high-performance servo motors, ensuring high precision, high speed, large torque, and stable performance. This guarantees the machine’s structural stability, good rigidity, lightweight design, and high dynamic response.

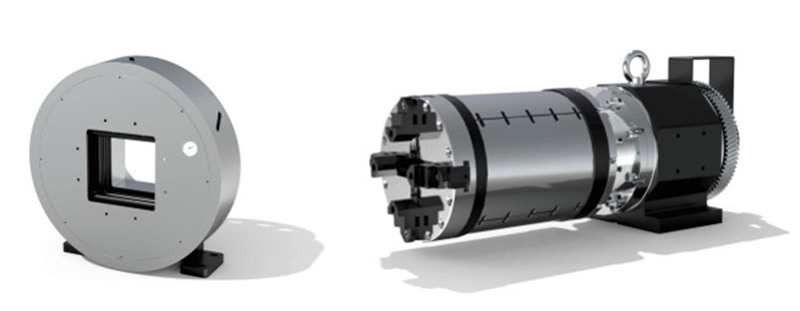

- Both front and rear chucks employ a four-jaw pneumatic clamping structure for securing pipes. The symmetrical movement of the chucks ensures automatic centering without the need for manual intervention. A pressure regulating valve is installed for convenient adjustment of air pressure.

- The semi-automatic feeding mechanism supports pipe diameters ranging from Ø20mm to Ø110mm. Pipes are manually arranged with a maximum weight capacity of ≤800kg, loading length of ≤6000mm, and individual pipe weight of ≤86kg. After the detected pipe is in place, the lifting and dividing device feeds the pipe to the front feeding robotic arm. Upon reaching the designated position, the front end of the feeding robotic arm retracts, clamping the pipe, allowing it to slide to the center of the cutting machine. An auxiliary support rises, clamping the positioned pipe, and the feeding robotic arm returns to its original position. At this point, the rear chuck moves forward to clamp the pipe, and the cutting program is initiated.

- Employing the FSCUT3000DE CNC system based on the Windows operating system, the dedicated BaiChu fiber laser tube cutting machine integrates numerous specialized laser cutting control modules, ensuring powerful functionality and user-friendly interface for simple operation.

- The FSCUT3000DE Expert Edition nesting software is essential for achieving “continuous cutting, efficient cutting, and high nesting rate cutting” on the CNC cutting machine. This software significantly saves materials and enhances cutting efficiency.

- The cutting head offers the option of internationally renowned Wan Shun Xing company’s fiber laser-specific cutting head and capacitive sensing, ensuring high precision, responsive performance, and stable reliability.

Chuck

| Front Clamp | RK110 | Back Clamp | RK110 |

| Single Claw Stroke | 50mm | Single Claw Stroke | 30mm |

| Single Claw Thrust | 60kgf | Single Claw Thrust | 50kgf |

| Clamping Range | 10-160mm | Clamping Range | 10-160mm |

| Rated Speed (r/min) | 140 | Rated Speed (r/min) | 140 |

Laser Cutting System Software

- FSCUT3000DE is a control system software developed specifically for tube processing. It supports high-precision and efficient cutting of various materials such as square tubes, round tubes, raceway shapes, ellipses, angle steel, and channel steel. It is an upgraded version of FSCUT3000S.

- In terms of special steel alignment, the software supports the alignment of various special steels such as L steel, channel steel, and I-beams, improving the cutting accuracy of special steels.

- The Pipe Surface Profile Correction feature effectively compensates for systematic cutting deviations in stable pipe surfaces, reducing the precision requirements for raw materials and minimizing waste.

- The Single-Side Alignment function effectively addresses the accuracy issues of pipe hole positions, improving the precision of hole positions near the edges. One-click alignment of the pipe head using the cutting head reduces manual alignment time and minimizes front-end waste.

- The Start and Stop Cutting Processes address issues such as excessive power burning to the opposite side at the cutting starting point and the potential for leaving small tails when cutting thin pipes.

- For processing the end of pipes, the software can control the loosening of the center chuck, increasing the Y-axis travel distance and cutting capacity, effectively reducing waste from both chucks.

Application

This metal tube fiber laser cutting system is widely used to cut various metal pipes and tubes for complex metal parts, prototypes and custom parts in a cost-effective and economical laser cutting capabilities. It is widely used to cut various pipes and tubes, for example, stainless steel, carbon steel, galvanized, aluminum, etc.

Reviews

There are no reviews yet.