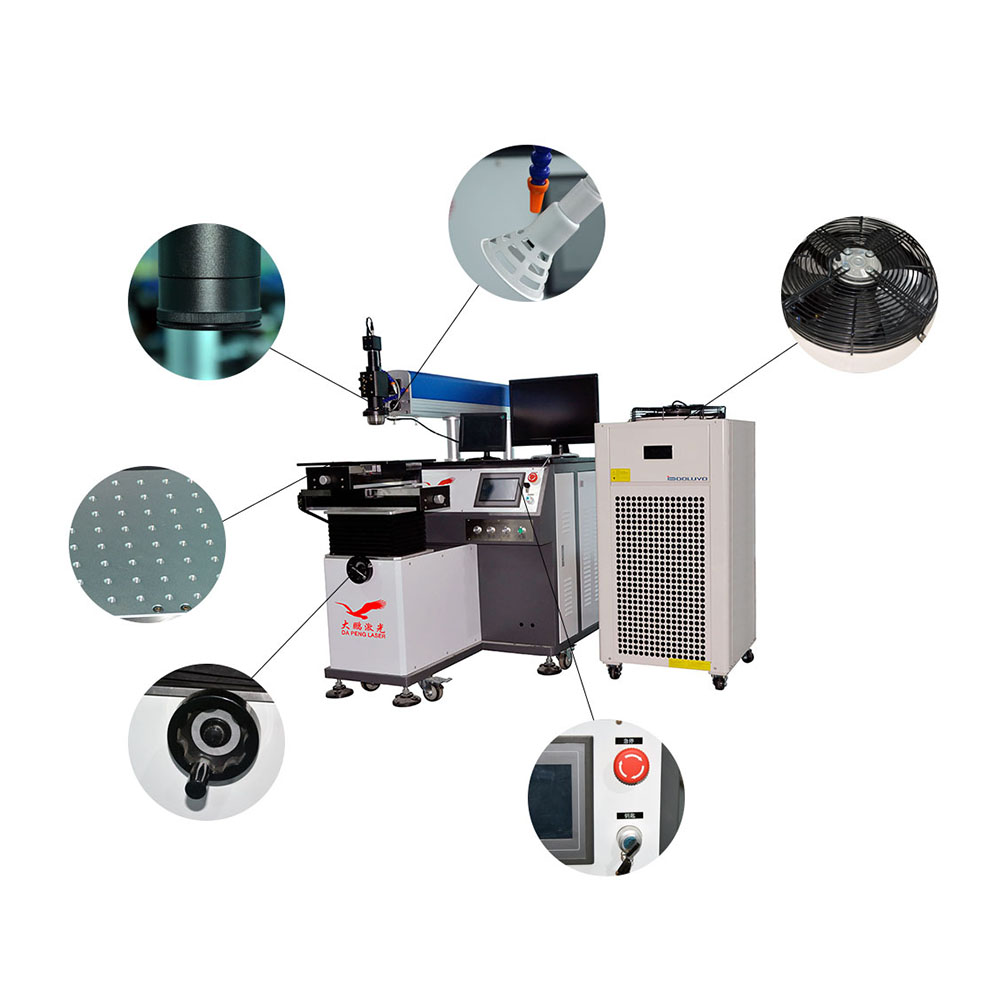

200W Automatic Fiber Laser Welding Machine for Metal Two-axis External Chiller

The welding process of automatic laser welding machine is simple. The non-contact welding method can meet the requirements of cleanling and environmental protection. With laser welding, you can produce workpieces with the highest level of precision. Superior quality weld seams require hardly any reworking. At the same time, automatic laser welding system provide highly work efficiency for large quantities with high repeatability or flexibility for changing lot sizes.

1064nm YAG Automatic Laser Welder:

- The use of laser welding to process workpieces can improve work efficiency, and the finished workpiece has beautiful appearance, small weld seam, large welding depth and high welding quality.

- Laser welding can realize spot welding, butt welding, stack welding and sealing welding of thin-walled materials and precision parts.

- Complete complex plane straight line, arc and arbitrary trajectory welding.

- It can meet 24-hour mass production and is suitable for large production enterprises or users.

- Adopt special laser welding control system with stable performance and simple operation.

Support for Customization

200W, 400W, 600W, 2-axis, 3-axis, 4-axis, customized fixtures, Automatic YAG laser welding machine for metals

Multi-axis linkage automatic laser welding machine is equipped with multi-dimensional ball screw table and imported servo control system, which can complete automatic or semi-automatic spot welding, butt welding, stack welding, seal welding and arbitrary trajectory welding of complex plane straight line and circular arc. The Multi-axis auto laser welding machine is easy to operate, the current waveform can be freely adjusted, the welding precision is high, the speed is fast and the effect is excellent. Meanwhile, it can be combined with assembly line, photoelectric sensor, fixture, etc. to realize fully automatic laser processing.

Applications:

200W metal automatic YAG laser welding machine can achieve seam welding, T-welding, overlap welding, edge welding, etc. Widely used in the welding of Stainless steel, die steel, carbon steel, nickel, zinc, aluminum, the laser welding machine can also be used in lighting, mold repair and other communication equipment, medical treatment, electronics, automobile industry, biomedicine, BT20 titanium alloy, HEI30 alloy, L1-ion battery, etc.