Automatic Flying Laser Marking Machine

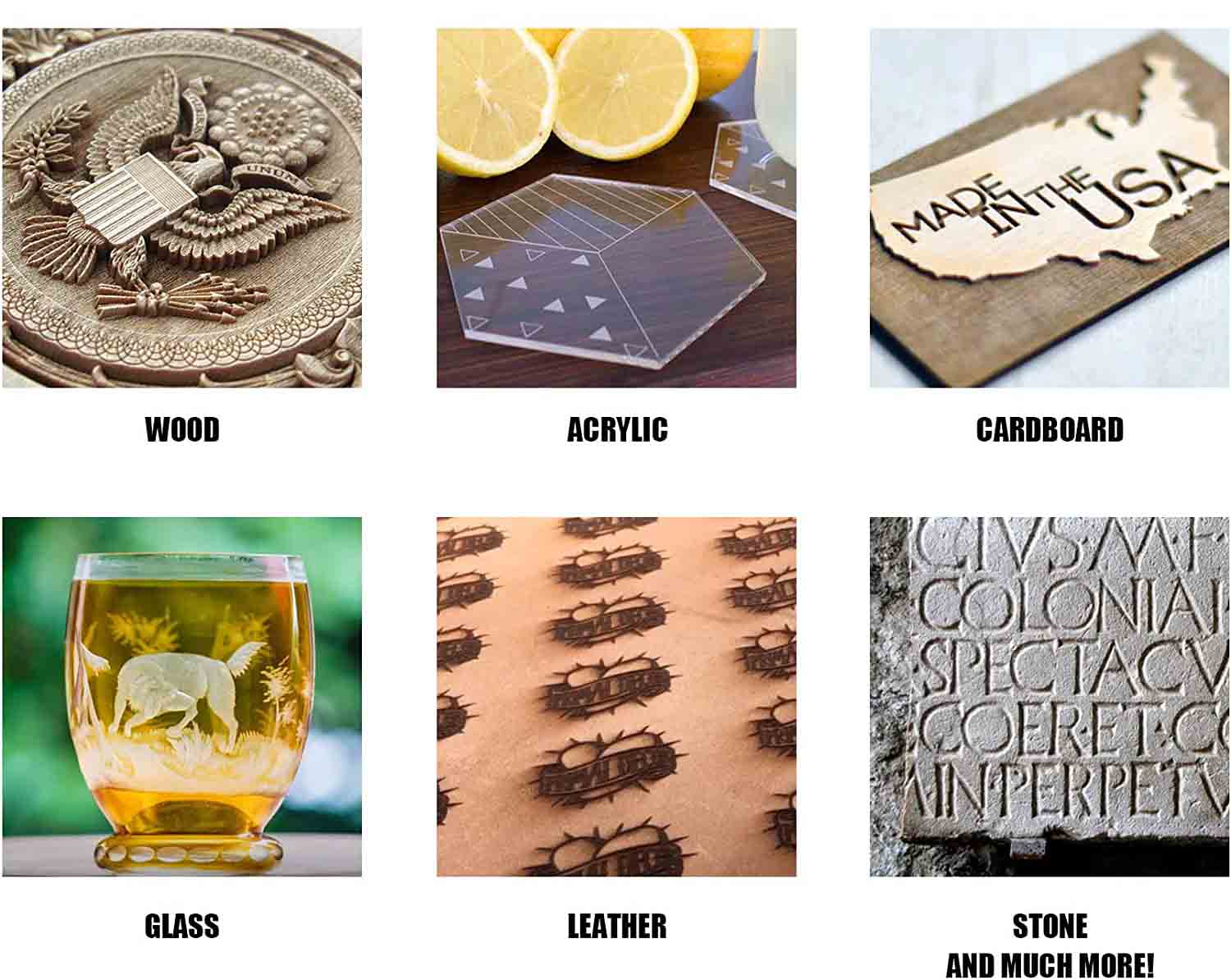

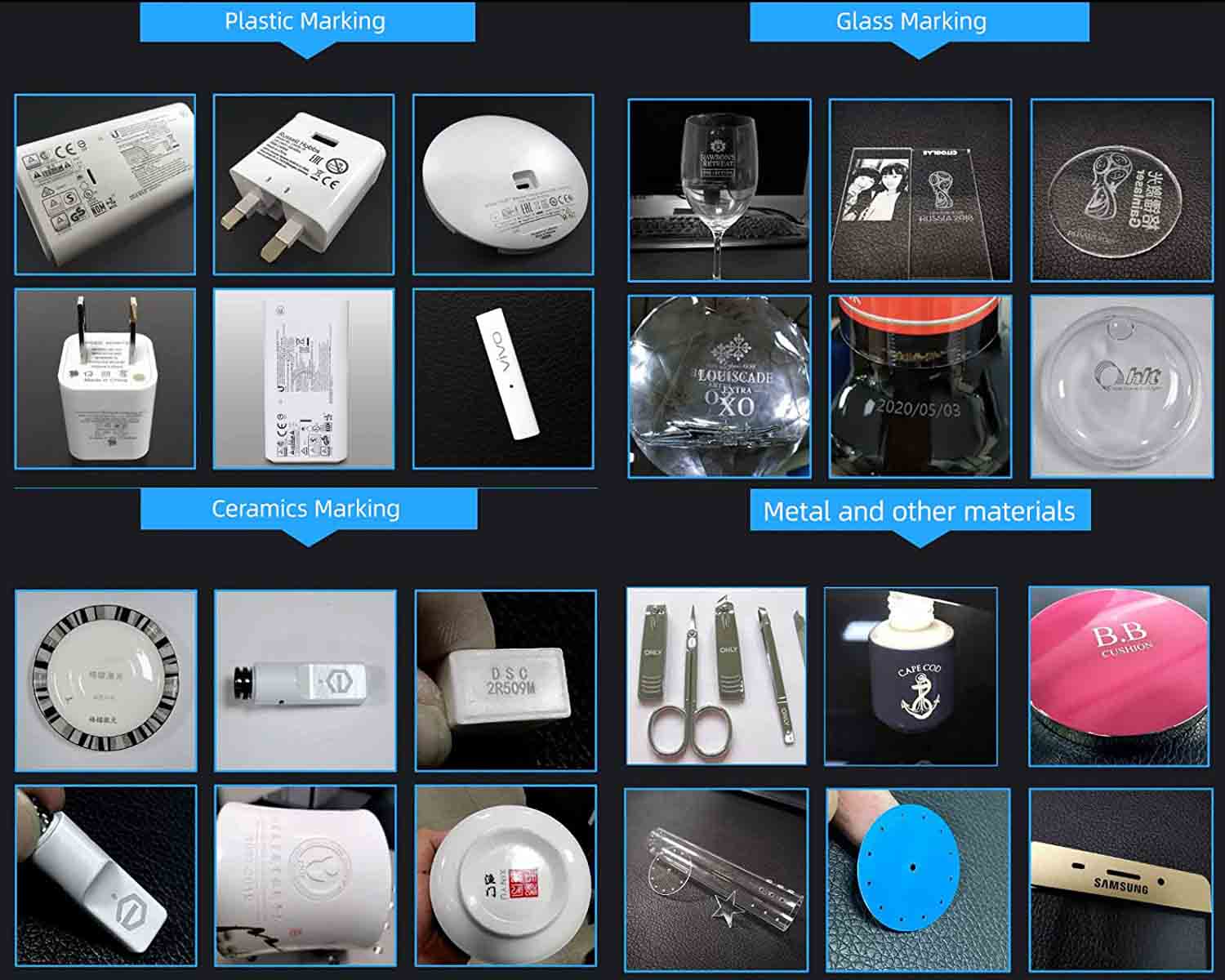

Flying online laser marking system with automated conveyor is equipped with fiber laser, CO2 laser source, and UV laser source, allowing for marking on both metal and non-metal materials, such as metal sheets, glass, plastic, acrylic, wood, and fabric, among others. It can print permanent codes and information on glass bottles while the conveyor is in operation. Importantly, the laser marking machine does not require any consumables, leading to significant cost savings in production.

Automatic CO2 fiber UV fly laser markers suitable for precision and fine logo printing on electronic products and components, auto parts, hardware tool products, precision instruments, food and beverage packaging, glasses, medical equipment, medal & craft gift making etc.

Features:

1. Cost and Labor Reduction: Traditional printing methods often require manual labor for loading and positioning parts for marking. Laser marking on the fly eliminates the need for manual intervention, reducing labor costs and the potential for human errors.

2. Improved ROI: Laser marking on the fly can lead to a significant improvement in return on investment (ROI) compared to other forms of marking. The increased speed and efficiency of the process can result in higher throughput and lower production costs over time.

3. Continuous Production Flow: With on-the-fly laser marking, parts can be marked as they move seamlessly along the production line. This continuous flow of parts ensures that the manufacturing process remains uninterrupted, contributing to increased productivity and reduced cycle times.

4. Adaptability to Part Orientation: Vision systems integrated with laser marking machines can identify and adapt to variations in part orientation. This flexibility allows parts to arrive in the laser field in different orientations, and the laser system can automatically adjust to ensure accurate and consistent marking, even at high speeds.

5. High-Speed Marking: Laser marking on the fly is known for its high-speed capabilities. The use of galvanometer scanners and precision optics enables rapid marking without compromising quality or accuracy.

6. Customization and Versatility: Laser marking technology allows for the customization of markings, making it suitable for various applications, including text, logos, serial numbers, barcodes, and more. This versatility makes it an ideal choice for industries with diverse marking requirements.

7. Precision and Consistency: Laser marking delivers precise and consistent markings, ensuring product quality and traceability. This is especially important in industries where product identification and traceability are critical, such as aerospace, automotive, and medical device manufacturing.

8. Part Alignment: The ability of the laser system to adapt to different part orientations means less time is spent on manual adjustments or additional handling to ensure that parts are positioned correctly for marking.

|

Laser Source

A CO2 laser utilizes a mixture of gases as the gain medium, including carbon dioxide, helium, nitrogen, and possibly some hydrogen, water vapor, and xenon. This type of laser is electrically pumped by gas discharge, which can be achieved using direct current, alternating current, or radiofrequency. |

| ScanQuick3 Scanning Galvanometer λ=10.6um

The L Series high-speed scanning galvanometers accommodate mirrors with a spot size of 14mm to 18mm, ideal for optical scanning, laser marking, drilling, micro-processing, and medical industrial applications. This system offers low drift, high positioning accuracy, and reliable operation, supporting mirrors with different wavelengths and power levels, and adhering to the XY2-100 international standard protocol. |

|

|

Lens λ=10.6um/9.3um

The F-theta scanning lens, also known as a field lens, flat-field focusing lens, or linear lens, has an image height equal to the focal length multiplied by the scanning angle (y=f *θ). Unlike typical focusing lenses that concentrate the beam into a single point, the scanning lens disperses the laser beam into multiple points over the scanning area or workpiece, creating uniformly sized focused spots across the entire marking plane. |

| Control Software: EzCad

Software Kernel: 32-bit or 64-bit. Laser Support: Supports CO2, YAG, FIBER, etc. The software can adjust parameters such as current, pulse frequency, and duty cycle based on different laser parameters. IO Control: Added port control function, enabling easy automation of the machine (one input port, two output ports). Multi-language Support: Built-in Chinese, English, Korean, Japanese, French, German. It can be easily localized by using language packs for translation. |

|

|

Industrial PC (IPC)

The industrial PC chassis adopts a steel structure, providing high resistance to magnetic interference, dust, and shocks. It features a dedicated motherboard with PCI and ISA slots. Additionally, it is equipped with a specialized power supply unit boasting strong anti-interference capabilities. |

| Computer Monitor

HKC 21.5-inch V2210 – 178-degree viewing angle – Flicker-free technology – 16.7 million colors – Low power consumption ≤0.5W – Resolution/Refresh Rate: 1920*1080/60Hz – Dot pitch: 0.248mm – Display colors: 16.7M – Brightness: 220cd/m² – Contrast ratio (DCR): 20,000,000:1 |

|

Applications of Flying Online Laser Engraver:

Automatic CO2 fiber UV fly laser markers suitable for precision and fine logo printing on electronic products and components, auto parts, hardware tool products, precision instruments, food and beverage packaging, glasses, medical equipment, medal & craft gift making etc.

- Product Traceability: These machines are commonly used in industries like automotive, electronics, machine part to mark serial numbers, barcodes, QR codes, and other identification information on parts and products for traceability and quality control.

- Packaging: Flying laser markers are used to mark packaging materials like cartons, labels, and foils with logos, expiration dates, batch numbers, and other product information.

- Cutting and Engraving: In addition to marking, some flying systems are equipped with the capability to cut and engrave materials like plastics, metals, and wood.

Automatic focus flying laser marking system is typically used in industries such as electronics, e-cigarettes, pharmaceuticals, and food packaging, where high-speed and continuous marking on products or components is required. These machines offer advantages such as increased production efficiency, reduced downtime, and the ability to achieve precise and permanent marking on a variety of materials, including metals, plastics, ceramics, and more.

Reviews

There are no reviews yet.