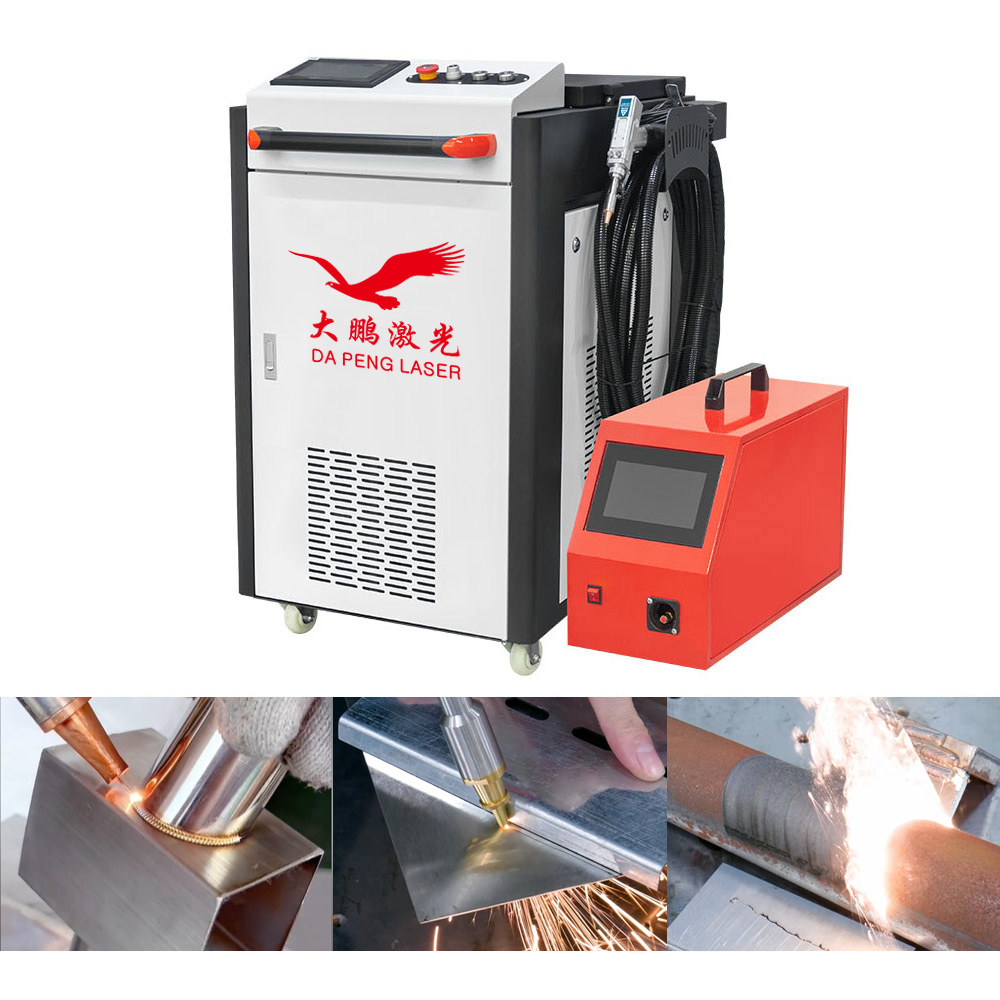

3 in 1 Handheld Fiber Laser Machine for Cleaning Welding Cutting with Automatic Wire Feeder

3 in 1 handheld fiber laser welding machine is composed of fiber laser generator, 3 in 1 handheld laser gun, water chiller, and control system, which is used for handheld welding, cleaning and cutting. Its handheld laser guns can weld, cut and metals and clean rust, paint, resin, coatings, oil, and stains. Users can perform multiple tasks with just one machine, no need to purchase and operate multiple machines. The 3 in 1 laser welding system can be adapted to various brands of fiber lasers, and the optical system and water-cooled design is optimized so that the laser head can work stably for a long time even at 3000W and 6000W power.

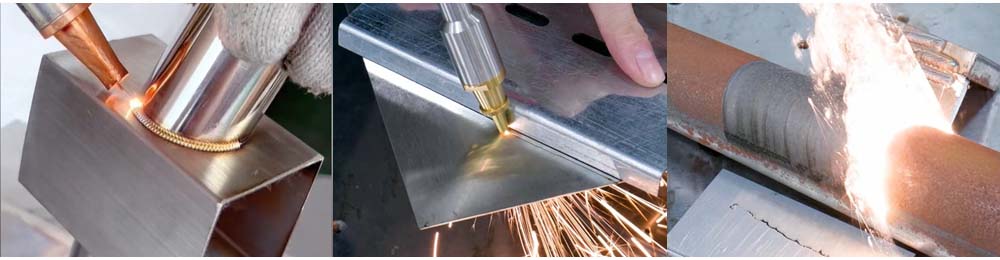

Laser Welding

This machine allows for precision laser welding of various materials, including metals like steel, aluminum, and copper. With the ability to deliver high-power laser output, it enables efficient and accurate welding operations. The handheld laser welding systems is easy to learn and operate, capable of producing high-quality welding results on various materials and thicknesses. The weld seams are smooth and aesthetically pleasing, requiring no secondary grinding or post-processing. The high-speed welding efficiency contributes to increased productivity. This handheld metal laser welding machine has 5 in 1 metal welding functions, including spot welding, seam welding, pulse welding, continuous welding and repair welding, which can meet a variety of welding needs.

Laser Cleaning

The fiber laser welding machine is also capable of laser cleaning, which is a non-abrasive method used to remove contaminants, rust removal, paint, and oxides from the surface of different materials. It offers a fast and efficient way to clean surfaces without damaging the base material.

Laser Cutting

By focusing a high-power laser beam on specific areas, it serves as an effective auxiliary cutting tool for metal materials, including galvanized sheets, carbon steel, aluminum, and stainless steel. It is especially well-suited for cutting thin metal sheets.

3 in 1 laser welding machine with triple functions of laser welding, cleaning, and cutting simultaneously. It can quickly and easily remove oil, rust, and coatings before welding, and clean debris and welding seam after welding, while performing various sheet metal cutting processes. It can conveniently and efficiently assist customers in achieving optimal work efficiency and meet the requirements of most working scenarios.

- 3 in 1 Handheld Laser Gun: The handheld laser gun offers welding, cleaning, welding seam cleaning and cutting capabilities through an intelligent controller. It facilitates flexible processing, is compact and portable, and comes with low operating costs due to it requires no consumables.

- Mobile Use: Handheld 3 in 1 welding gun, 10m fiber optic cable length.

- Compact: Small size, high flexibility, wider working range, can be used in onsite, factory, outdoor applications.

- Easy Function Switching: Welding function converts to cleaning function by simply replacing the focusing lens and laser head.

- Laser Source Options: Options for fiber laser generators include brands like Raycus, MAX, which offer higher photoelectric conversion efficiency, lower power consumption, maintenance-free operation, and a compact structure.

- Built-in Cooling System Design: The built-in cooling system design, making it compact and portable for various production. It also provides excellent dust protection.

- Intelligent Control System: With an integrated parameter adjustment range and one-touch start feature, the intelligent control panel ensures simplicity and ease of use.

3 in 1 Laser Welder Cutter Cleaner Features

Portable design: These handheld laser welders are compact and portable, making them easy to carry and operate in different settings.

Multifunction: These welders have three functions, including laser welding, laser cutting, and laser cleaning, making them versatile tools for different welding applications.

High precision: These laser welders are capable of achieving high levels of precision, leading to accurate and aesthetically pleasing welds.

Wide range of metal weldability: These handheld laser welders can weld a wide range of metals, including stainless steel, aluminum, copper, brass, titanium, and others.

User-friendly control system: Most 3 in 1 handheld laser welders feature a user-friendly control panel that is easy to understand and use, making it easy to adjust power and frequency settings.

Safety design: To reduce the risk of accidents, these handheld laser welders come equipped with various safety design and alarm that prevent damage to the machine or injury to the user.

3 in 1 Handheld Laser Welding, Cleaning, Cutting Machine

Advanced Laser Source: User-friendly and efficient, achieving faster and more precise results than TIG/MIG welding!

Digital Control System:The operation screen features a user-friendly touchscreen and intuitive operating system. Easily adjust welding parameters and switch between multiple welding modes at will. From precise spot welding to continuous welding, it ensures optimal results and consistent quality every time. Even beginners can get started quickly.

Humanized Design: Our hadheld laser welding gun is lightweight, ergonomic design weighs just 0.8kg. It’s built for comfort during long hours of work.

HandHeld Laser Welding Mode

Various Metal Materials

|

|

|

|

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel |

laser welding copper |

Laser Cleaning VS Traditional:

- No damage to substrates, better appearance of molded.

- Laser cleaning machine is the high efficiency, energy saving metal laser cleaning equipment.

- Simple operation, can be hand-held or with manipulator to achieve automatic cleaning.

- Flexibility, removes almost any organic material

- Laser cleaning since rust is removed with greater precisionis, it is a great alternative to manual and chemical cleaning methods.

- Non-contact 360° cleaning, not limited by space and location, environmentally friendly without consumables.

- With universal casters, it is easy to move and install.

3 in 1 Handheld Laser Welder Cleaer Cutter Applications:

It was applied to steel, stainless steel, aluminum alloy, carbon steel, aluminum plate, hardware sheet metal, copper, etc. Laser non-contact enables cleaning, welding and cutting processes. The Multipurpose laser equiment is used in manufacturing including bracelet earrings necklace customization, advertising industry, building material, lithium battery, mining, farms, clothing stores, machine shops, manufacturing plants, construction engineering and other industries with complex welding, cutting and cleaning processes.

Why Choose DPLASER ?

Quality Management

According to the IS09001 quality management system, our company controls the finalized products in their incoming materials, processing process, complete machine and shipment to ensure the performance and quality of the shipped products. Several product series have obtained EU CE certification.

Service Network

The company has set up a marketing management center, sales and service network.

The network covers the whole country, all over the world. DPLASER has established a complete production, sales and after-sales service system, established a laser industrial park in Nantong, Jiangsu, Shenzhen, Wenzhou, Suzhou. We more than 20 offices in major domestic industrial cities and regions office, each office has equipment display, process proofing, sales and after-sales service, resident technical service personnel, to provide customers with timely and comfortable pre-sale, sale and after-sale support and services.

Rich Product

DPLASER provides comprehensive laser solutions and supporting facilities for the manufacturing industry. Our main product lines include laser welding machines, laser marking machines, laser cutting machines, laser drilling machines, ultrafast laser micromachining machines, and customized non-standard equipment. With over 200 types of industrial laser equipment, we offer diverse solutions to meet various manufacturing needs.

FAQs

Q1: What functions does the 3 in 1 laser welding machine offer?

A: It integrates laser welding, laser cutting, and laser cleaning into one unit, allowing flexible switching between functions for multiple applications.

Q2: What are the advantages of the all in one laser welding machine?

A: It is easy to operate, produces clean and aesthetically pleasing welds with minimal heat-affected zones, and offers high efficiency. It supports a wide range of metal materials, helping reduce equipment investment and save workshop space.

Q3: Which industries are best suited for the 3-in-1 laser welding machine?

A: It is ideal for sheet metal processing, hardware manufacturing, machinery production, kitchen and bathroom equipment, signage, and repair industries.

Q4: Is the laser welding machine safe to use?

A: The laser machine includes multiple safety features such as temperature control, light-locking, and anti-misoperation systems. Compared to traditional TIG welding, laser welding offers better control and enhanced safety with significantly reduced exposure to harmful radiation. When operators wear proper protective gear like laser goggles and gloves, it is very safe.

Q5: What’s the difference between the cleaning function of a 3-in-1 laser welder and fiber laser cleaning machine?

A: The 3-in-1 machine is suitable for light rust and surface contamination, making it ideal for daily maintenance and small applications. Professional laser cleaning machines offer higher power and efficiency, making them better suited for precision components and large-area industrial cleaning tasks.

Q6: How about the price? Can you make it cheaper?

A: The price depends on your configuration and requirements (function, size, quantity). We will quote you the best discount after receiving your inquiry. Please contact us via WhatsApp now!