The term “water cooling plate,” also known as “liquid cooling plate,” “Water Cooling Radiator,” or “Liquid Cooling Heat Sinks,” typically refers to a cooling component made of aluminum, designed for heat dissipation purposes. It is primarily used in high-power devices such as servers, variable frequency drives, inverters, electric motors, large batteries, Active Power Filters (APF), Static Var Generators (SVG), Insulated Gate Bipolar Transistors (IGBT), and more. These liquid cooling panels are customized based on customer application, including material, shape, manufacturing process, size, power capacity, and application industry. In this article, we will explore the impact of battery cooling plate laser welding, offering innovative solutions for cooling components welding.

Compared to traditional cars, new energy vehicles demand higher temperature management for batteries, motors, and electronic components. Currently, the main cooled solutions include air cooling, liquid cooling, and direct cooling. With the lower cost of liquid cooling plates and the increasing requirements for battery safety and performance, liquid cooling has emerged as the dominant technology for battery cooling method.

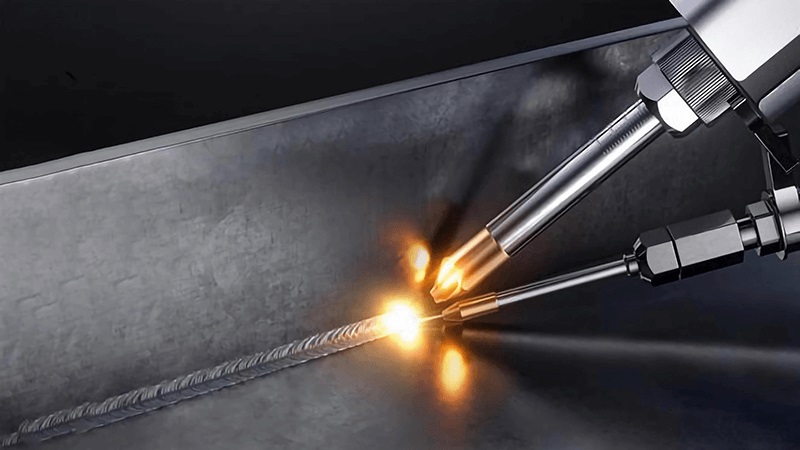

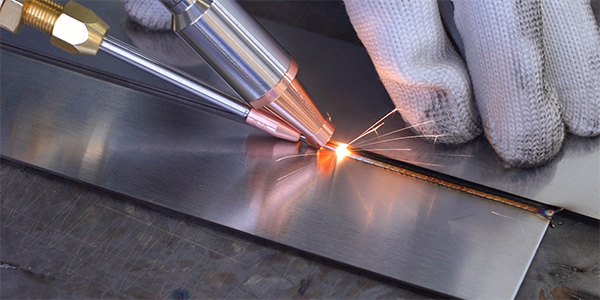

The new energy vehicle manufacturers prioritize the performance of thermal management systems, with the welding quality of the liquid cooling plate, directly affecting the reliability and safety of new energy vehicles. The battery cooling system in new energy vehicles primarily consists of critical components such as the battery, battery cooler, and liquid cooling plate. EV battery cooling plate laser welding requires extremely high-quality sealed joints to prevent any coolant leakage during the cooling cycle. These joints must be free from any cracks, as they can lead to mechanical failures.

Liquid Cold Plate Welding Process

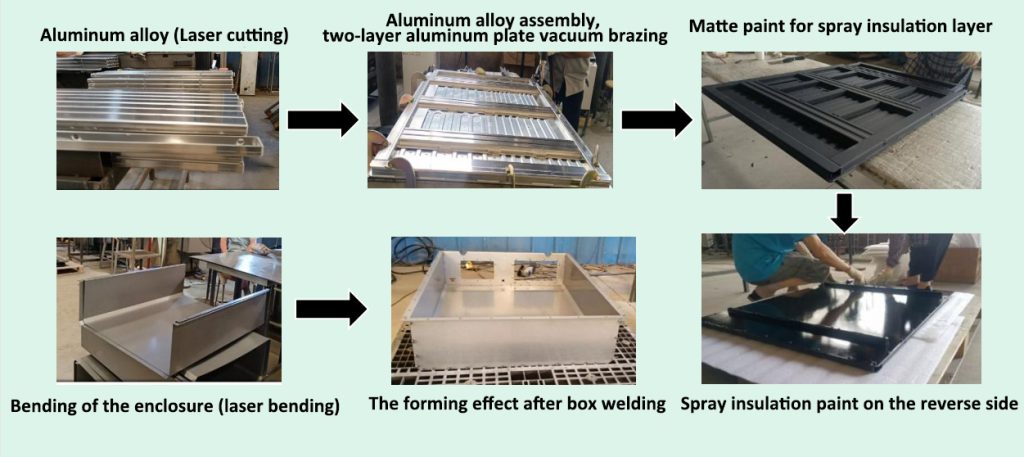

Liquid cooling plate manufacturing involves various welding processes such as vacuum brazing, friction stir welding, nitrogen shielded welding, argon arc welding, laser welding, diffusion welding, and more. Each of these welding methods serves different roles in the fabrication of liquid cold plates. Apart from considering the material’s inherent strength and the product’s corrosion resistance, the primary concern is ensuring welding quality.

Copper cold plate products typically employ vacuum brazing, while aluminum cold plate products often use friction stir welding. When it comes to laser welding for liquid cold plate manufacturing, it offers several advantages over brazing.

Laser welding joints have minimal changes in the heat-affected zone, lower stress levels, and do not affect the overall hardness. The process is conducive to mechanization, automation, and has low energy consumption. It demands minimal requirements for the working environment and doesn’t necessitate pre-drilled holes in the product. However, it’s worth noting that laser welding devices are generally straightforward in structure and may require further improvements for certain specialized welding needs, such as achieving better results in complex water channel designs for liquid cold plates through hybrid friction stir welding.

Welding Methods of Water Cooling Plate for Heat

Laser welding is one of the recommended methods for battery liquid cold plate welding. Why is it advisable to use laser welding instead of traditional methods for EV battery cooling plate? The rationale behind this recommendation lies in the numerous advantages offered by laser welding, including CNC precise control over accuracy, speed, and welding quality. All of these factors are of paramount importance for the safety and performance of electric vehicles and new energy applications. Here are some advantages of using laser welding for battery cooling plate applications:

Vacuum Brazing: High strength, void-free, suitable for high-temperature applications, expensive equipment, and complex operation.

Friction Stir Welding: No melting involved, suitable for difficult-to-weld materials, high strength, no porosity, suitable for thicker materials, relatively slower speed.

Nitrogen Shielded Welding: High-quality welding, suitable for various materials, control over weld appearance, high operational requirements, slower speed, requires gas shielding.

Argon Arc Welding: High efficiency, fast speed, not suitable for all materials.

Diffusion Welding: High-temperature applications, high-strength connections, require high temperature and pressure, relatively longer manufacturing time.

Laser Welding: High precision, high-speed welding, small heat-affected zone, suitable for complex geometries, expensive equipment, suitable for thin materials.

Why Choose Laser for Battery Cooling Plate Welding?

High-Precision Welding: Laser welding boasts exceptional welding precision, allowing for the joining of tiny seams and complex geometric shapes, making it well-suited for the intricate manufacturing requirements of liquid cold plates.

Small Heat-Affected Zone: Laser welding generates an exceedingly small heat-affected zone, reducing the risk of material deformation and thermal stress, thereby helping to maintain the dimensions and performance stability of the liquid cold plate.

High-Speed Welding: Laser welding is a high-speed welding method that can enhance production efficiency, making it suitable for large-scale manufacturing demands.

Quality Welds: Laser welding produces high-quality, clean welds with minimal porosity or defects. This ensures the integrity of the cooling plate, preventing leaks or weak points that could compromise the battery’s performance or safety.

Non-Contact Welding: Laser welding is a non-contact welding method that eliminates the need for physical contact with the workpiece surface, reducing the risks of contamination and damage.

No Filler Material Required: Laser welding typically does not necessitate additional filler materials, reducing costs and material wastage. Compared to traditional welding processes, laser welding lowers production expenses and enhances manufacturing flexibility and selectivity.

Suitable for Various Materials: Laser material processing can join a variety of materials, thus meeting the diverse material requirements for liquid cold plates.

Laser Technology Application for Heat Sink Liquid Cooling Plate

Liquid Cold Plate Welding Cost

The battery cooling plate laser welding cost can vary widely depending on several factors. These factors include the welding method chosen, the materials used, labor costs, equipment costs, and the complexity of the design.

The production of water cold plates requires tooling and welding, and the liquid cold plate price is also determined by different manufacturing processes and requirements. In the field of new energy, liquid cold plates typically cost around $800 per plate, while cooling plates for power generation equipment can be reduced to $300 per plate.

Liquid Cooled Heat Sink Application Industry

– Electronics and Power Industry

– Electric Vehicles

– Energy Storage and Temperature Control Industry

– Semiconductor Industry

– Smart Manufacturing Industry

– New Energy Industry

– Power Plants (Hydro, Thermal, Photovoltaic)

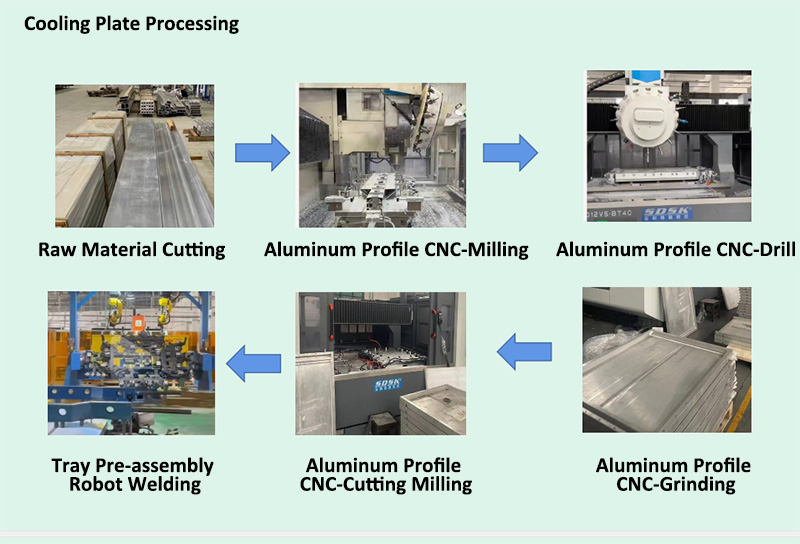

Water-Cooled Plate Laser Processing

Chassis Liquid Cooling Process

After the liquid cooling plate welding is completed, customers need to do following tests:

1) Leak Test

2) Seal Test

3) Destructive Testing

4) Customers are required to have safety certification qualifications.

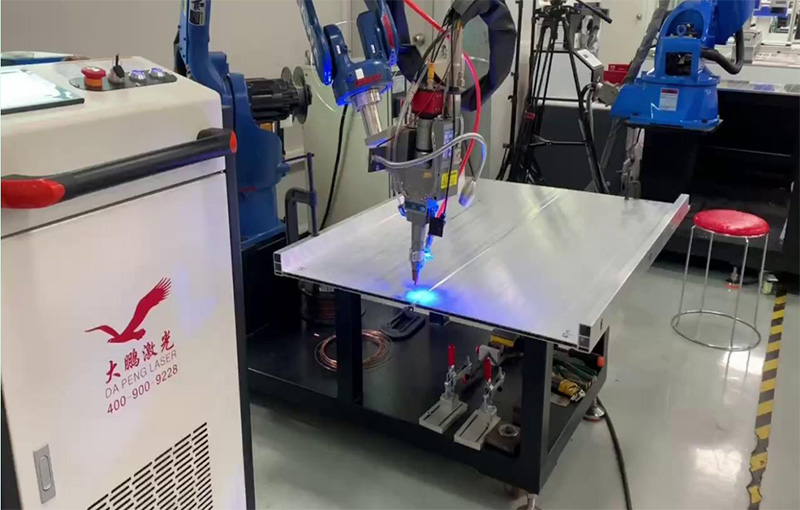

DPLASER Laser Robot Solution for Liquid Cooling System

To meet requirements such as sealing, collision safety, productivity, and flexibility in high-precision welding of internal components of battery liquid cooling plates and battery casings while maintaining process reliability, DPLASER offers innovative robotic liquid cooling plate welding solutions for the manufacturing and integration of cooling systems. This creates the optimal production conditions for reliable and high-performance battery packs.

Laser Welding Solution: Battery liquid cooling plates typically consist of multiple thin plates that require welding at various locations. With laser welding robots flexible arms and intelligent path planning algorithms, can perform welding operations in complex structural environments, achieving a high level of automation and accuracy.

Laser Cleaning Solution: Whether it’s paint, oxides, rust, or grease residue, automated cleaning robots offer a variety of laser cleaning solutions to address issues like pre- and post-welding surface contaminants. These robots efficiently and precisely use laser technology to clean welding surfaces, providing a better environment and conditions for welding. They typically possess intelligent sensing and navigation capabilities, allowing for precise positioning and cleaning operations based on the characteristics of the welding surface.

Laser Cutting Solution: Laser cutting robots are capable of processing complex shapes. Battery liquid cooling plates often have intricate structures and shapes that require precise cutting according to design specifications. Equipped with high-precision control systems and intelligent path planning algorithms, laser cutting robots can swiftly complete tasks involving complex shape cutting, thereby enhancing production efficiency.

Laser Marking Solution: Laser marking machines play a crucial role in EV battery liquid cooling plate manufacturing by marking QR codes, enabling verification and tracking, facilitating personalized customization, and enhancing anti-counterfeiting measures. By employing laser marking technology, you can achieve permanent, gentle, and flexible marking requirements, thus improving product traceability and quality management.

Whether it’s cutting, bending, or welding, we provide comprehensive laser solutions for all liquid cold plate welding. Benefit from our decades of application experience in various component processes and laser equipment implementations, you can receive professional support and guidance to ensure that your laser equipment operates stably for an extended period and achieves the expected performance.

Robot arms equipped with laser equipment require a deep understanding of laser technology. Many robot suppliers may not be well-versed in laser processes, leading to difficulties in resolving post-sales issues. We are a specialized laser equipment manufacturer with a dedicated team of experts in robotics research and development, offering cost-effective solutions to address all your needs in one station and providing top-quality after-sales service.

Conclusion:

In order to improve performance, safety, and productivity, laser welding for liquid cold plate manufacturing provides an indispensable tool. Laser technology has brought exceptional precision, speed, and superior control for complex component welding quality, significantly enhancing various industries such as electric vehicles, new energy, and semiconductors. The integration of laser welding precision with automation is driving many emerging industries towards a future of high-end manufacturing.