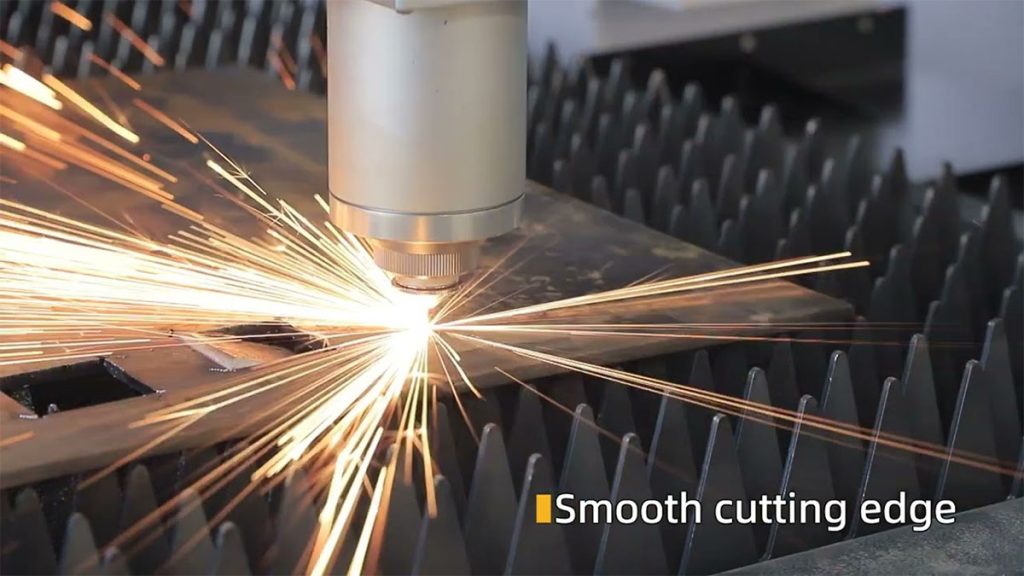

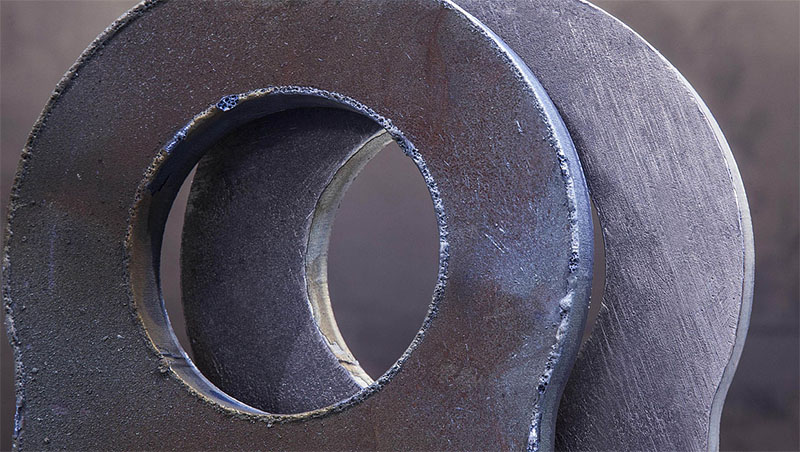

Burr refers to various sharp corners, burrs and other irregular metal parts that appear at the transition of the workpiece surface in laser cutting processing. These burrs will affect the dimensional accuracy, shape accuracy and surface roughness of the processed parts, thus reducing product quality. In addition to the direct impact on product quality, burrs will also cause a series of problems in the subsequent inspection, assembly, performance and aesthetic aspects. Therefore, in order to ensure product quality, laser cut metal parts should be avoided as much as possible to produce burrs. This article discusses how to reduce burr in laser cutting and is designed to help your cutting projects.

What Factors Produced Burr in Laser Cutting?

Here I will analyze several common reasons for the generation of burrs in laser cutting and corresponding solutions.

During laser cutting, the laser beam irradiates the surface of the workpiece, generating extremely high temperatures that rapidly vaporize and evaporate the surface of the workpiece, achieving the purpose of cutting metal. The role of the auxiliary gas is to blow away the residual slag on the surface of the workpiece after it has been vaporized by the laser beam. If this is not done, when the slag cools, it will form an attached burr on the cutting surface of the workpiece.

Reason 1: The laser beam focus of the laser cutting machine has a deviation in the vertical position, resulting in insufficient energy focusing on the workpiece, preventing complete vaporization, increasing slag production, and making it difficult to effectively blow away, thus easily forming burrs.

Solution: Regularly calibrate the laser cutting machine, check the focus, and adjust it appropriately. This helps achieve burr-free cutting. Sometimes, there may be deviations in the position of the beam.

Reason 2: Insufficient output power of the laser cutting machine, leading to ineffective vaporization of metal and the generation of excessive slag and burrs.

Solution: First, check whether the laser cutting machine is in optimal condition, especially the output value. Timely maintenance to ensure the machine operates at the best output power is crucial for reducing burrs. Test and choose the appropriate laser cutting machine power to achieve optimal cutting results.

Reason 3: The cutting line speed of the laser cutting machine is too slow, damaging the surface quality of the cutting face and causing burrs.

Solution: It is necessary to control the cutting speed. If the cutting speed is too fast, the material may not burn completely, and the workpiece will not be cut through. On the other hand, if the cutting speed is too slow, the workpiece may burn excessively, leading to melting and deformation. Adjust and increase the cutting line speed promptly.

Reason 4: The purity of the auxiliary gas in the laser cutting machine does not meet the standard, resulting in the generation of burrs on the workpiece.

Solution: Replace the auxiliary gas with high purity, and nitrogen is preferred because it is a non-combustible gas that can immediately oxidize and melt metal, preventing burrs. When using CO2 and fiber laser cutters, increase the purity of the auxiliary gas to 99.95% or higher (99.98 or 99.99%) to significantly improve cutting speed in production.

Reason 5: The laser cutting machine operates for an extended period, causing the equipment to be in an unstable state and promoting the generation of burrs.

Solution: Shut down the laser cutting machine, restart it after a proper rest, and ensure that the equipment gets sufficient rest.

Increasing the Smoothness of Cutting Metal Cross-Section

By adjusting the nozzle height and cutting air pressure, the laser cutting process can be optimized to enhance the smoothness of the cutting cross-section, ensuring improved process stability while maintaining cutting quality.

Selecting the appropriate nozzle

The nozzle plays a crucial role in laser cutting by precisely controlling the quality of laser cutting through the regulation of the spraying area of the auxiliary gas. Therefore, parameters such as the structure, dimensions, and height of the nozzle directly impact the final cutting result. Damaged parts of the nozzle can lead to uneven airflow, affecting cutting quality.

Materials with different cutting thicknesses require nozzles with corresponding diameters. For instance, a Φ1.2 nozzle is suitable for stainless steel sheets with a thickness of 1-6mm, while a Φ2.0 nozzle is suitable for stainless steel sheets with a thickness of 6-10mm.

During the laser cutting process, users need to pay constant attention to protecting the nozzle to prevent collisions, deformation, or localized melting. Additionally, for optimal laser cutting results, the nozzle needs to maintain coaxially with the laser beam.

It is also essential to pay attention to the distance between the nozzle and the workpiece, as the nozzle height affects beam quality, oxygen purity, and airflow direction. Lowering the nozzle results in better beam quality, higher oxygen purity, and smaller airflow direction.

Gas Pressure

Different metal materials require different optimal gas pressures. If the pressure is too low, melted materials may not be blown away promptly, leading to adhesion on the back of the cutting edge. If the gas pressure is too high, it weakens the cutting ability of the laser beam, resulting in larger and rougher cut seams. To ensure the smoothness of the cutting cross-section, it is recommended to control the pressure within an appropriate range. Generally, reducing the pressure helps achieve a brighter cutting cross-section. Still, to ensure cutting stability, a certain proportion can be added to moderate pressure.

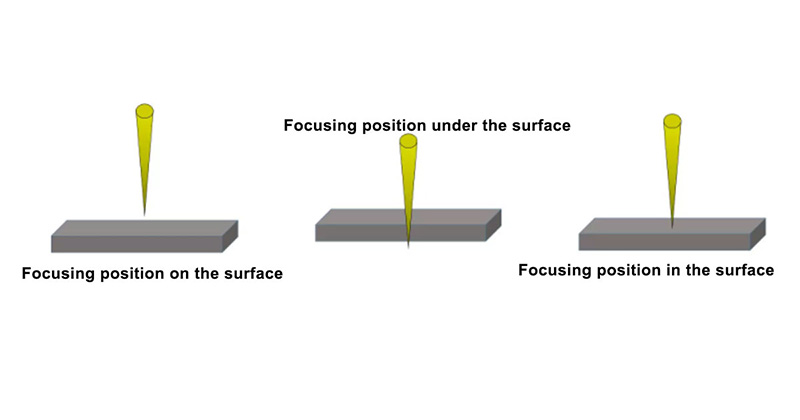

How to Select the Right Focal Length for Laser Cutting

When processing different workpieces, it is essential to adjust the focus mode selectively and match factors such as cutting gas, gas pressure, and cutting speed to ensure the optimal processing results.

The impact of focus position on laser cutting is manifold, influencing beam diameter, power density on the workpiece surface, and the cut’s shape. Directly modifying the focus position affects cut width. By adjusting the focal length, the focus diameter becomes flexible. Changing the focus position essentially varies the spot size on the surface and within the sheet. Increasing the focal length thickens the spot, widening the cut and impacting heating area, cut size, and slag removal ability.

Zero Focus Cutting

At the zero focus point, the spot is minimal, yielding a narrow cut. This is suitable for precision cutting of thin sheets, offering fast cutting speeds, especially applicable to thin metal sheets.

Positive Focus Cutting

Positive focus cutting produces a smooth cross-section but at a relatively slower speed. It is more fitting for cutting medium-thick plates with higher section quality requirements. As sheet thickness increases, the focus position rises, suitable for various materials and processes, such as stainless steel with nitrogen/air cutting, carbon steel with oxygen cutting, etc.

Negative Focus Cutting

Negative focus cutting is faster, approximately double the speed of positive focus, but results in a relatively rough cut. This method is preferable for cutting medium-thick plates with lower section quality demands. As sheet thickness increases, the focus position decreases, suitable for processes like carbon steel with oxygen cutting, aluminum, and brass with nitrogen/air cutting, carbon steel with nitrogen/air cutting, stainless steel with nitrogen/air cutting, etc.

How to Cut Clear Acrylic with Laser?

Acrylic has a reputation for being a striking material due to its luster, transparency, optical clarity and rich colors. This material is usually supplied in sheet form, and to create items with specific shapes or patterns on demand, laser cutting becomes one of the quickest and easiest options. With laser cutting, precise and delicate cuts can be achieved, further enhancing the appearance of the finished panel.

Laser cutting acrylic plate has the advantages of high precision, narrow kerf, fast speed and smooth cutting surface. But because the laser focusing energy will melt the acrylic, so there will be a jagged phenomenon in the cutting process, that is, the edge of the cut is carbonized. So how to make the laser cut acrylic smoother?

1. Choose the appropriate laser: CO2 laser cutting machines are a common choice because their emitted laser falls within the infrared range, allowing absorption by acrylic of any color.

2. Consider the laser machine’s power: Sufficient power helps achieve single-pass cutting or engraving, saving time and providing optimal results. High power and appropriate speed ensure cutting through acrylic in one pass, avoiding secondary processing and carbonization.

3. Ensure single-pass completion: While ensuring single-pass cutting through, select moderate laser power and speed to avoid secondary damage and burrs. High power and slow speed should be adjusted to ensure wood is cut through in one pass, increasing cutting speed and power under the premise of achieving a single pass. Lowering power may lead to multiple cuts, exacerbating carbonization.

4. Choose the appropriate acrylic grade and color: Different grades and colors of acrylic have varying effects on laser cutting, so it’s essential to choose materials that suit specific needs.

Cast acrylic and extruded acrylic are two common types of materials, both possessing characteristics suitable for laser cutting and engraving. By selecting an appropriate industrial laser cutting machine and adjusting cutting parameters, you can easily achieve precise cutting of acrylic, resulting in high-quality finished products.

We specialize in providing customized laser cutting solutions to meet various needs. To better cater to your expectations, we offer a convenient sample mailing service. Simply send us your samples, provide detailed information about your specific requirements, and our experienced engineering team will conduct free sample testing for you. We will tailor the most suitable laser cutting solution for your needs.

The Bottom Line:

In the continuing development of laser cutting machines, obtaining smoother cut edges has been one of the key challenges for the manufacturing industry. This article explores in detail the causes and solutions of laser cutting leave burrs and provides practical advice for different situations. Through an in-depth study of material selection, focal length adjustment and other aspects, we hope to have provided you with effective solutions to help you achieve smoother, more accurate cutting results.