In modern commercial manufacturing, it is vital to employ laser technology to improve productivity and product quality. This post involves the advantages of laser marking versus traditional printing methods, as well as practical applications in manufacturing, medical and creative fields. Discover how to start laser engraving business with important advantages and lead to success.

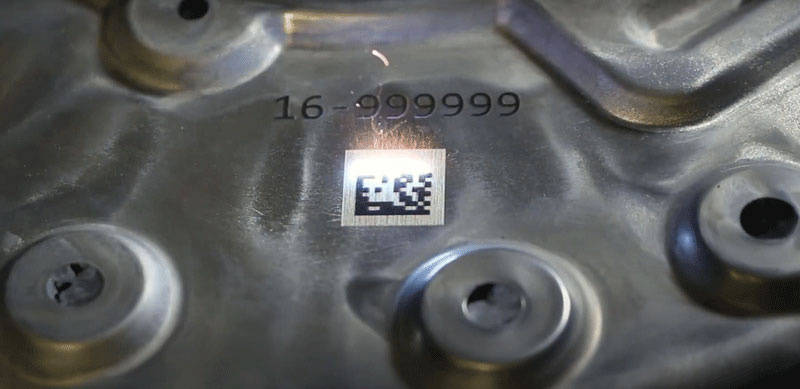

Laser marking machines achieve marking of patterns, barcodes, logos and characters by using different types of laser beams to irradiate different material surfaces and trigger physical or chemical changes in the surface material. This technology allows high precision marking on a wide range of materials to meet the needs of different industries.

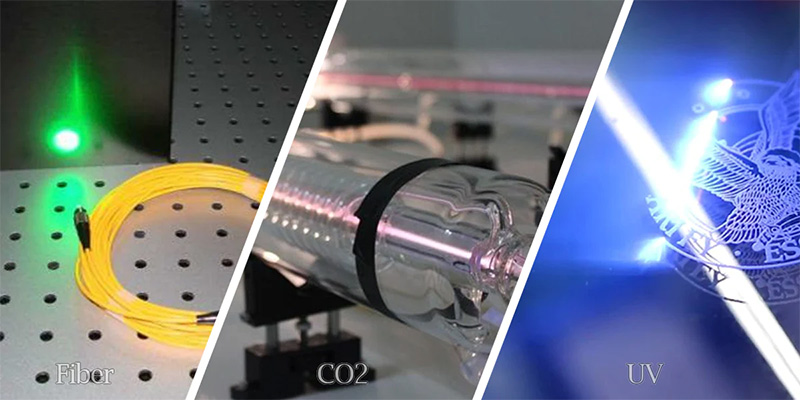

There are three main types of laser marking machines: fiber laser marking machine, CO2 laser marking machine, and UV laser marking machine. Each type is suitable for different applications based on the laser’s wavelength and power. The choice of machine depends on the characteristics of the material and the desired marking precision and quality.

Laser marking system are used in a wide variety of applications including, electronic components, integrated circuits (ICs), electronic products, tool accessories, precision instruments, eyeglasses and clocks, jewelry, automotive accessories, plastic products, product packaging, and PVC pipes.

Fiber laser marking machines are suitable for most metallic materials and some high-density plastic materials such as glass, polymers, electronic components, hardware, jewelry, and tobacco. It is particularly effective for marking and engraving metal surfaces.

CO2 laser engraver machine are typically used on most non-metallic materials, including paper, leather, wood, plastic, glass, fabric, acrylic, wood and bamboo, rubber, crystal, jade, ceramics, glass, and artificial stone. These laser markers are suitable for applications that require clear marking and engraving of non-metallic surfaces.

UV laser markers are mainly used for applications that require fine marking and engraving, such as marking on semiconductor materials, micro pores, glass cutting, and silicon wafer cutting. UV lasers have shorter wavelengths, which allow for higher resolution and fineness.

Laser Engraving vs. Traditional Engraving: Benefits of Laser Marking for Your Business

Non-Contact Processing: Laser marking is a non-contact processing method in which the laser beam is directed at the surface of the workpiece without physical contact, thus reducing the risk of wear and damage to the workpiece.

High precision: laser marking can achieve very high precision and resolution. It can accurately draw complex patterns, text or logos on the surface of the workpiece, making it suitable for applications that require high-precision marking.

Highly efficient processing: Laser marking is fast and can mark a large number of workpiece in a very short time. This is very favorable for mass production and efficient production lines. Laser marking technology can be easily integrated into automated production lines for unmanned and highly automated production processes.

Less consumables: Unlike some traditional printing and engraving methods, laser marking does not require consumables such as ink, graphite or engraving knives, thus saving costs and environmental resources.

Wide applicability: Laser marking can be used on different types of materials, including metal, plastic, ceramics, glass, etc. It is widely applicable and can meet the needs of many industries.

Permanent marking: The marking effect of laser marking is usually permanent and cannot be easily worn, faded or removed. This is important in applications that require long-term marking.

Flexibility: The laser marking system can be highly flexible by adjusting the parameters and the position of the focus point of the beam through the control system to achieve different types of marking effects, such as deep scribing, shallow scribing, and color changes.

How Laser Marking Enhance Your Business?

Laser marking system can significantly enhance an organization’s business by providing the advantages of high-quality permanent marking, efficient production, real-time tracking and anti-counterfeiting protection. By applying laser marking technology, companies can not only improve product quality and efficiency, but also enhance their brand image, strengthen market competitiveness, and provide a better shopping experience for their customers.

Laser Engraver How Enhance Your Business

Laser marking and engraving on fabric

Laser marking machines have a wide range of applications in the field of clothing marking. Mainly used on leather fabrics, the advantage of laser marking machine lies in its ability to engrave and skeletonize various patterns quickly and accurately. What’s more, it will not cause any deformation of the leather surface, thus perfectly retaining the natural color and texture of the leather. As a result, laser marking machines are highly popular in the manufacturing fields of shoes, shoe uppers, bags, leather goods, handbags, leather garments and so on. Clothing studio can take full advantage of the capabilities of laser marking machines to enhance their creative and production processes.

Laser marking for fashion and clothing industry

Customized Designs: Individual apparel studios can use laser marking machines to custom design their clients’ garments. This involves engraving personalized patterns, logos, text, or decorative elements on fabrics to meet a customer’s specific needs. This customized design can enhance the uniqueness of the garment and increase its market appeal.

Producing Labels and Logos: Laser marking machines can be used to produce labels, logos and emblems for garments. These logos often require high precision and detail, and laser marking machines enable crisp marking and engraving to ensure logo quality and longevity.

Material Engraving: Laser marking machines can also be used to engrave different types of fabrics such as leather, silk and linen. This can add unique textures and decorations to garments to enhance their fashion sense and quality.

Cutting and Sewing Aid: Laser marking machines can mark the position of cut lines and seams during the cutting and sewing process to improve production efficiency and accuracy.

Laser marking machines provide a powerful tool for individual apparel studios to help them realize creative and customization requirements while improving production efficiency and quality.

Laser engraving crafts small business

Many craft manufacturing studios starting a laser engraving business are replacing the traditional handmade method of making woodblock prints. Artists can now have their computer-created graphics accurately engraved onto a wooden plate by laser scanning technology in order to preserve and carve out the unevenness of the pattern. This method offers a high degree of precision and control, allowing for fine adjustments in depth and area, ultimately producing prints that can be used for topography.

Making Patterns and Details: laser engraving can realize very fine and intricate patterns, texts and details, which make the crafts more artistic and unique.

Producing Personalized Crafts: Producers can create personalized crafts according to customers’ needs and requirements, such as items engraved with names, dates or special logos.

Material Cutting and Engraving: Laser engraving machines can be used to cut and engrave a variety of materials including wood, glass, leather, plastic, metal, etc. in order to quickly create different types of crafts.

Decoration and Logo Making: laser engraving can be used to make decorative elements and logos for crafts to enhance their visual appeal and market competitiveness.

Complex Structure Production: Laser engraving technology allows makers to create complex structures and textures on crafts, thus presenting more creative and design possibilities.

Laser engraving machine has become one of the common tools in crafts. It offers highly accurate and efficient cutting and surface scanning compared to traditional processing methods, allowing artists to express their work in a more creative way. Due to the different properties of different materials, laser engraving technology can give a special burnished texture to the material, presenting unique laser colors and textures.

Laser marking machine for packaging industry

Laser marking machine is the packaging and printing industry’s right-hand man, can be used for product packaging cartons, covers, product packaging and labeling marking and so on. Laser marking not only makes the packaging more sophisticated, but also makes the information clearer and permanent.

For designers and operators engaged in packaging and printing industry, laser marking machine helps to enhance the professionalism and attractiveness of product packaging.

Personalized Packaging: Laser marking technology can be used to personalize packaging with a sense of design, which helps to provide unique products and value-added services to attract more customers.

Brand Image: Small businesses can use laser marking to signify their brand and increase brand awareness and recognition. This helps to build brand image and attract more target customers.

Anti-counterfeiting and Quality Control: Laser marking can be used to add anti-counterfeiting logos and tracking codes to ensure product authenticity and traceability, enhancing consumer trust. It can also be used to mark product production dates, batch information and expiration dates to help maintain product quality and compliance.

Environmentally Friendly Packaging: Laser marking typically does not require the use of inks or chemical solvents, thus reducing the environmental impact of packaging and meeting the growing demand for sustainable packaging.

Decorative and Decorative Elements: Laser marking can be used for decorative elements and logo creation for packaging, improving its appearance and marketability.

Rapid Production and Iteration: Laser marking technology offers the ability to produce and iterate quickly. Startups can quickly build prototypes and test them in the marketplace, then make improvements based on feedback.

Customized Gifts: Small businesses can use laser marking to create customized gifts, such as items engraved with a customer’s name or a special design. This can add to the appeal of the product and provide a personalized gift option.

Laser marking technology provides individuals and small businesses with a powerful tool to enhance the creativity, quality and competitiveness of their package printing business.

Precision laser marking for medical & pharmaceutical industry

UV laser engraving machine using 355nm ultraviolet laser research and development, the beam is more detailed, faster out of the light, the beam quality is better. Marking effect through the short wavelength laser directly interrupts the molecular chain of the material, greatly reducing the mechanical deformation of the material.

In the process of processing materials, for conventional materials using the YAG laser marking machine and fiber laser marking machine can be competent, but fine ceramics, glass, PCB and other special materials marking need the UV laser engraving machine, the reason is that the ultraviolet laser engraving machine belongs to the cold process, in the processing of the thermal effect of the relatively low, incidental thermal damage Smaller.

Laser engraving machines usually use UV laser technology with high precision and fineness, and are suitable for marking, engraving, cutting and other various processing techniques on materials. They play an important role in different fields, such as date marking on food and pharmaceutical packaging, pattern engraving on leather products, and marking on electronic components. These applications usually require high quality and precision, which uv laser marking machines are able to fulfill.

Laser marking for iPhone back glass replacement

The use of UV laser engravers is becoming increasingly common in the field of cell phone repair. Cell phone screens are often made up of multiple layers of materials, including glass, plastic, metal and LCD screens, and removing these screens requires high precision and efficiency to ensure that no damage is done to the screen or other critical components.

UV laser engravers can provide fine cutting and engraving capabilities during cell phone repair and screen replacement. By controlling the intensity and focus of the laser beam, it can very precisely cut or engrave specific areas of a cell phone screen without causing damage to the surrounding area. This allows cell phone repairers to more easily remove and replace cell phone screens without introducing additional damage or defects.

How to Start Laser Engraving Business?

Laser marking technology is increasingly used in business and plays an important role in improving the efficiency and quality of business operations.

1. Precision: laser engraving machines can engrave details and lines with great precision, so the technology provides high precision engraving and cutting when it comes to demanding and intricately patterned products.

2. Customized Text: Laser engraving machines can imprint customized text, images or logos on products, such as letters, numbers, dates and logos.

3. Pattern Customization: Laser engraving machines can imprint intricate patterns, logos, fonts and shapes onto the surface of products. These customized and distinctive patterns help increase brand awareness as well as product appeal.

4. Automated Production Lines: Automatic laser marking machine allows for the integration of automated production lines, so companies can process orders and production schedules faster and more efficiently.

5. On-Demand Production: The cost of customizing and manufacturing products using laser engraving machines is relatively low, and there is flexibility to produce and manage inventory as needed.

Laser engraving machines provide businesses with exceptional tools for customization, personalization and digital production. They help companies improve productivity, product quality, and the responsiveness and fulfillment of consumer needs.

Summary:

Laser marking machine is an important industrial marking equipment, which plays a key role in production. It can not only improve production efficiency and product quality, but also achieve personalized customization to meet consumer demand. For enterprises, having a high-quality laser marking machine will bring a great competitive advantage. DPLASER as a company leading manufacturer of laser equipment, is committed to providing customers with high-quality, high-performance laser marking machine to help customers starting a laser engraving business.