When we refer to “portable laser welding machine,” we are primarily talking about handheld portable laser welding machine. The flexibility of handheld laser welding machines allows operators to easily carry and use them in various welding scenarios. Small handheld laser welding machines, also known as portable laser welding machines, are highly favored across various industries for their efficient welding capabilities, lightweight design, and user-friendly operation. This is particularly true in the field of metal welding.

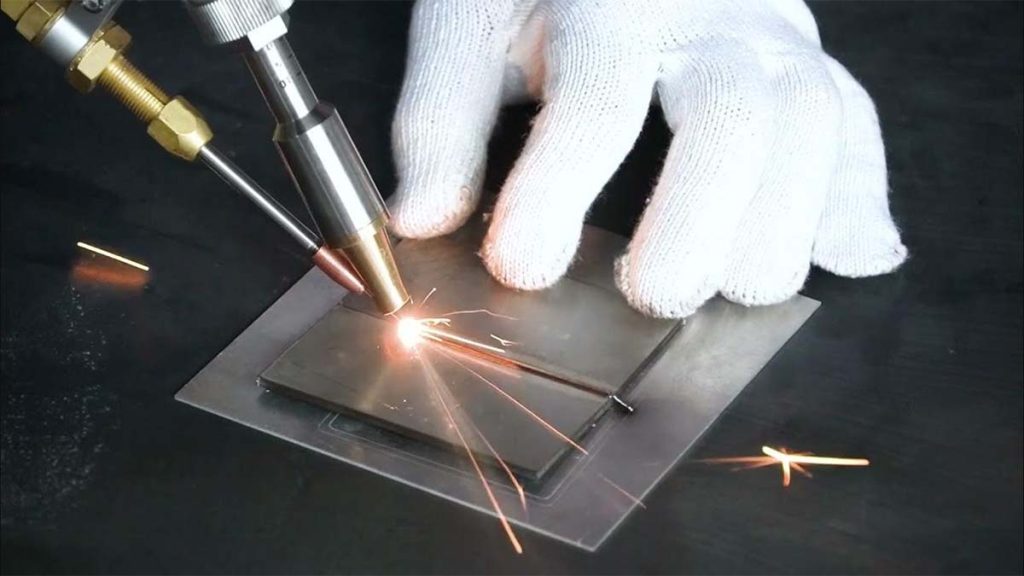

The portable handheld laser welder achieves highly precise welding processes. Its uniqueness lies in its applicability to various material types and complex designs, providing flexibility and wide applicability for industrial use. This device concentrates the heat source highly in a specific area, allowing for the precise melting and connection of materials, especially suitable for welding small components. The outstanding maneuverability of the handheld welding gun enables operators to freely control the welding angles and positions, providing convenience and high adjustability to meet various welding requirements.

Advantages of Handheld Portable Laser Welding Machine

Easy to use: First of all, from the point of view of operation, it is easier to use than other welding equipment. Even those who lack welding experience can quickly master the skills in a short period of time. More importantly, no welder’s license is required to operate the handheld laser welding machine, providing users with more flexible options.

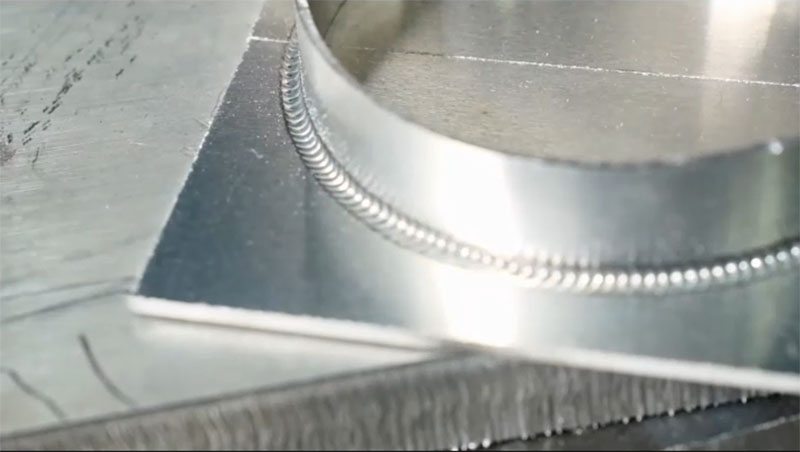

Accuracy: The high precision of the laser beam and the welding CNC system ensure precise control of the welding process, resulting in a perfect weld.

Welding Efficiency: Portable laser welding machines exhibit higher and faster welding efficiency than traditional welding methods due to their simple operation. With good seam conditions and the number of operations on the equipment, the efficiency of the handheld laser welding machine can even reach as much as 3-10 times of the traditional welding method.

Welding Effect: The weld seam is more aesthetically pleasing and basically takes shape in a single pass, eliminating the need for secondary grinding and thus eliminating the cost of grinding workers.

Minimal Distortion: The focused laser beam minimizes the heat affected zone. As a result, handheld laser welding reduces the risk of distortion of the weld material while maintaining its structural integrity.

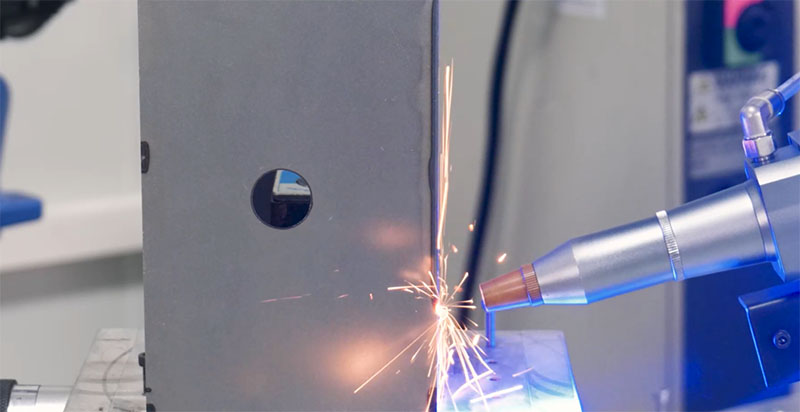

Compact design and versatility: Handheld portable laser welders offer a wide selection of torches, such as the common 3-in-1 and 4-in-1 function torches, which integrate multiple functions of welding, cutting and simple cleaning, enhancing their flexibility and versatility of applications.

4 In 1 Small Portable Laser Welding Machine

The 4 in 1 portable laser welding machine integrates four key functions commonly used in industrial production. In the fields of industrial manufacturing, repair and maintenance, as well as machining, this multifunctional laser welding machine demonstrates its unique versatility, offering users a wide range of applicability and flexibility. Whether it is complex production tasks or delicate machining needs, this state-of-the-art equipment meets the urgent need for efficient and precise welding.

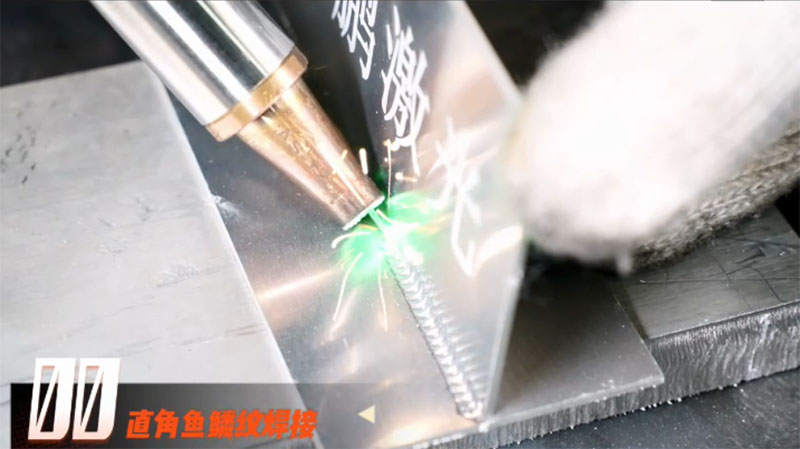

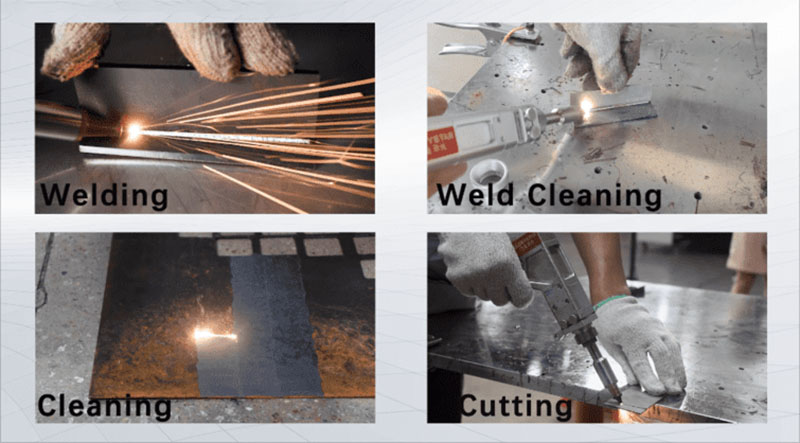

Laser Welding

The main function is welding. It is designed to join materials together using a high-powered laser beam, ensuring a precise and efficient welding process.

Laser Cleaning

It removes rust, contaminants or unwanted materials from the surface of the workpiece before and after welding, ensuring a clean, smooth surface.

Laser Cutting

It can be used to cut materials with high precision, making it a versatile tool for a wide range of applications requiring welding and cutting.

Seam Cleaning

Seam cleaning is a specific function related to welding. After welding, the tool cleans the weld seam to ensure a polished and finished appearance.

Portability and Compactness: The integration of four functions in one design makes the unit compact and easy to carry and move. Users don’t need to carry multiple separate units, which increases flexibility and convenience.

Space-saving: The integrated design utilizes space efficiently and reduces the work area occupied by the equipment, making it ideal for work environments with limited space. This helps to improve line efficiency and optimize the layout of the workplace.

Versatility: The integration of four key functions allows the machine to perform in a variety of welding situations. This eliminates the need to purchase multiple units with a single function, reducing equipment costs and management complexity.

Integrated control: The integrated design means that the equipment can be operated through a single control system, simplifying the process. Users can switch between different welding modes more easily, improving ease of use and operational efficiency.

However, handheld portable laser welding machines do come with some limitations. They are primarily designed for welding conventional small metal components and may not be as suitable for larger equipment. Additionally, there are thickness constraints, typically effective for materials below 7mm. If the material exceeds this thickness, the welding efficiency can be significantly impacted. Despite the relatively high initial investment cost, for instance, the 1500W portable laser welding machine price is approximately $8,000, when considering the efficiency improvements and the reduced labor costs compared to traditional welding methods, it proves to be a highly worthwhile investment.

As we delve into the working principles of portable laser welding machines and compare their advantages with traditional welding technologies, it becomes evident that handheld laser welding machines are increasingly gaining popularity in various parts manufacturing industries.

How to Use Portable Fiber Laser Welding Machine?

Before starting laser welding, it is essential to conduct thorough preparation. For more guidance for how to use a handheld portable laser welder, please refer to our laser welding machine YouTube playlist. Here is the most complete guide to laser welding.

Firstly, check the water level in the tank and ensure it is adequate. If it is found to be insufficient, promptly add distilled or pure water. Also, ensure that the wire feeder is correctly installed, and the selected welding wire meets the requirements.

Simultaneously, verify the proper installation of the welding head. Conduct a meticulous check on equipment such as power sources and protective gas supplies.

Correctly setting welding parameters is crucial. Adjust welding parameters based on the material, angle, and desired welding effects. This involves adjusting parameters in the wire feeder control system and welding operation, such as laser power, laser beam diameter, and welding speed. Due to the significant impact of different parameter settings on welding quality, it is imperative to carefully adjust each parameter.

Precisely position the object to be welded on the welding table and ensure it is securely fixed to ensure the accuracy of the welding operation, resulting in clear weld seams.

For welding different materials, adjusting the laser focal length is necessary. By adjusting the focal length, ensure that the laser welding effect can reach its optimal state. This step is crucial for achieving high-quality welding results.

2024 Best Portable Handheld Laser Welding Machine

DP LASER portable air-cooled laser welding machine features a compact design with efficient air cooling, weighing only 35kg. Easily packable, it can be taken anywhere for rapid welding tasks. Laser welding ensures clean and uniform results, reducing maintenance costs and enhancing welding speed.

Advanced Laser Technology: User-friendly and efficient, delivering faster and more precise results than TIG welding!

Adjustable Welding Parameters: Easily customize welding parameters for various welding modes, including fillet welding, corner welding, spot welding, flat welding, stack welding, and bevel welding.

The portable metal laser welding machine is highly versatile, efficiently handling laser welding tasks on various metals and alloys, such as aluminum, copper, nickel, titanium, carbon steel, galvanized sheets, and stainless steel. The laser welding system can also join different materials. However, it is essential to use appropriate filler materials and metals with similar thermal conductivity.

The welding capabilities of our handheld portable laser welders vary by power output and can weld the following thicknesses:

1000W portable laser welder: for welding carbon and stainless steel up to 3mm and aluminum up to 2mm.

1500W portable laser welder: for welding carbon and stainless steel up to 4mm long and aluminum up to 2.5mm.

2000W portable laser welder: Suitable for welding carbon and stainless steel up to 5mm and aluminum up to 3.5mm.

3000W portable laser welder: High-power portable laser welder handles carbon and stainless steel up to 7mm and aluminum up to 5mm.

For 3000w Dual Sided Welding: Excels at welding carbon and stainless steel up to 15mm thick and aluminum up to 10mm thick.

Portable handheld laser welding machine is a high-precision and high-efficiency industrial laser welding equipment, especially suitable for welding thin metal materials.

Where to Buy Portable Laser Welding Machine

Dapeng Laser is portable laser welder manufacturer, specializing in R&D, production, sales and service. Our products cover fiber laser cutting machine, laser welding machine, fiber laser cleaning machine and laser marking machine. We are proud that our laser cutting machines have successfully passed CE, FDA and ISO9001-2015 certifications, which signifies our excellence in product quality. With multiple service centers around the world, we are committed to providing localized service and technical support to our global customers to ensure that they enjoy perfect quality and service.

Local Service

We have a number of local dealer service points, while the global dealer recruitment is still in progress.

1) Equipped with showroom, sales manager, engineers and machines.

2) Prices, local technical support, components, features and warranty are all available at the same global level.

Pre-sales Service

1) Provide customized solutions and equipment information accordingly to customer’s development needs;

2) Producing solutions to problems according to the feasibility and development requirements of the local market;

After-sales Service

1) Seller provides free installation, technical guidance and training services at buyer’s factory.

2) Provide e-mail, telephone, WeChat, WhatsApp etc. for technical guidance.

3) If local maintenance is required during the warranty period, we will send engineers to the site.

In short, portable laser welding machines offer versatile and efficient solutions for a wide range of welding needs. Their compact design, lightweight construction and user-friendly features make them an indispensable part of a wide range of applications. Whether you are dealing with small metal parts or complex welding tasks on materials such as aluminum and stainless steel, these machines demonstrate excellent versatility. Benefit from favorable portable laser welding machine price, they not only improves the speed and quality of the welding process, but also help cost saving and operational efficiency.