Acrylic, also known as plexiglass, is a high-transparency, visually appealing polymer material with excellent plasticity. It is crystal-clear with a soft light reflection and exhibits outstanding color vibrancy after dyeing. With superior weather resistance, surface hardness, and high-temperature stability, acrylic finds extensive applications in advertising, interior decoration, architecture, lighting, and handcrafted gifts.

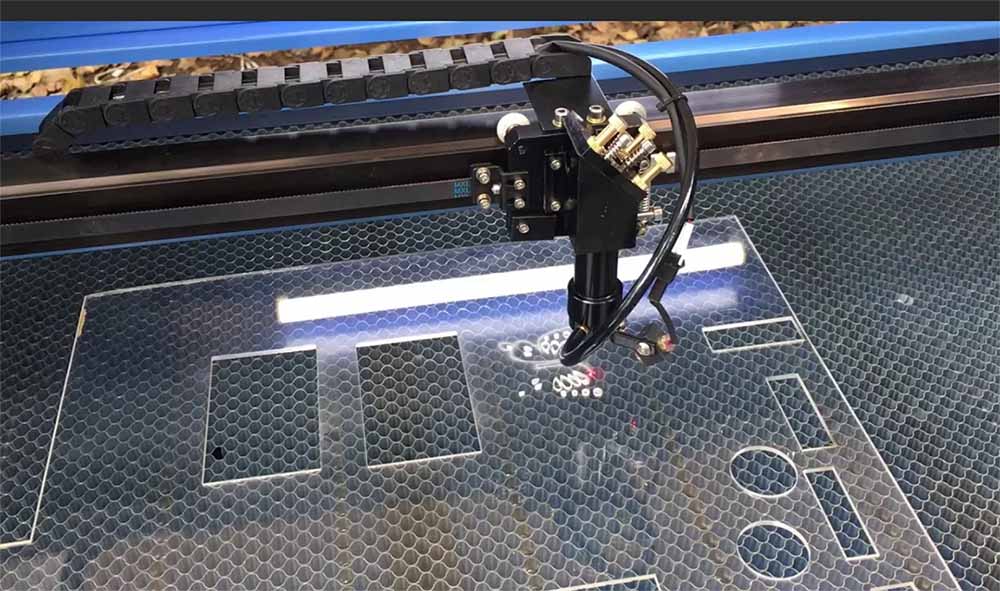

Laser cutter for acrylic and wood with remarkable efficiency. Controlled by computers and utilizing focused laser beams, these machines are capable of precise cutting and intricate engraving on materials such as acrylic, dual-color boards, ABS sheets, rubber, plastic, fabric, leather, wool, crystal, glass, tiles, jade, and bamboo. CO2 laser cutting machines deliver intricate details and smooth edges, making them the ideal choice for acrylic processing.

Can You Cut Acrylic with A Laser Cutter?

Yes, you can use laser cutting acrylic sheets, and it is one of the most common materials used in laser cutting projects. Laser cutters are highly effective for cutting, engraving, and etching acrylic sheets, producing clean and precise results.

Can Any Laser Cutting Machine be used to Cut Acrylic?

Not all laser cutting machines are suitable for cutting acrylic. CO₂ laser cutting machines are the preferred choice for acrylic processing, as their wavelength (typically 10.6 microns) and power output are perfectly suited for cutting and engraving non-metallic materials. CO₂ lasers can achieve efficient cutting and engraving without damaging the material, while ensuring smooth edges with no need for secondary finishing.

Does Laser Cutting Acrylic Produce Smoke?

Yes, laser cutting acrylic does produce smoke. It is essential to have a ventilation system in place to effectively reduce the spread of smoke and dust, ensuring safe operation.

How does an Acrylic Laser Cutting Machine Work?

Acrylic laser cutting machines use a high-powered laser beam to precisely cut or engrave acrylic sheets. The laser is focused onto the material, where it melts, burns, or vaporizes the acrylic along the design path. The machine’s movement is controlled by computer software, ensuring accurate cuts and smooth edges.

What can an Acrylic Laser Cutter Do?

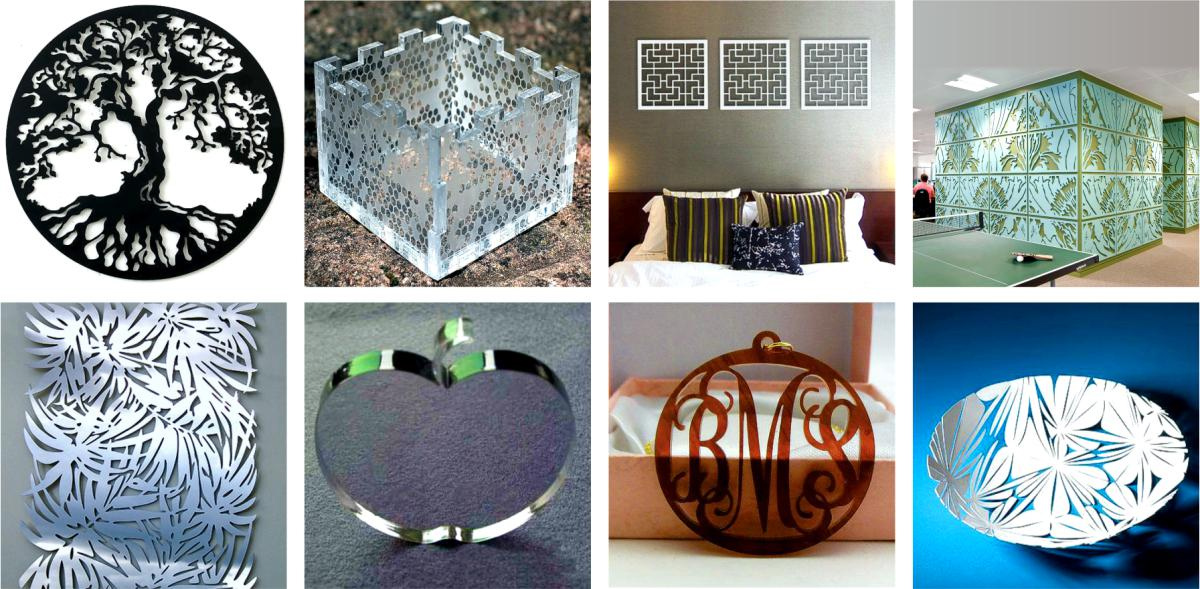

2D Cutting Designs: Laser cutting machines handle straight and curved lines with ease, making them ideal for creating various flat designs such as text, logos, geometric shapes, and more.

Engraving and Etching: Beyond cutting, the machine can adjust its parameters for surface engraving or etching, allowing for intricate textures or patterns to be created on the acrylic surface.

3D Structures: By assembling multiple 2D-cut pieces or using specialized programming to control the laser head’s angle and movement, complex 3D structures can be produced, such as models, display stands, lampshades, and more.

Advantages of Laser Cutting Acrylic

High Edge Quality: Laser cutting achieves precise cuts on acrylic sheets, leaving smooth, polished edges that require no additional finishing.

High Precision: With an extremely narrow cutting line width (around 0.3mm), laser cutting is ideal for intricate designs, ensuring excellent cutting results.

High Efficiency: Laser cutting combines speed with precision. For instance, cutting 3mm or thinner acrylic sheets typically achieves speeds of 10~30 cm/min.

Non-Contact Cutting: The process requires no physical contact, reducing the risk of material damage and eliminating the need for fixtures.

Cost-Effective: Laser cutters are ready to operate without preheating or mold preparation, saving both time and costs.

Flexible Design Capability: Powered by CNC technology, laser cutters can precisely create complex shapes and patterns, significantly expanding design possibilities.

Industrial-Grade Performance: As an industrial-grade cutting method, laser cutting integrates with automated systems for efficient workflows, enhancing productivity and product quality.

Environmentally Friendly: Laser cutting optimizes energy use, reducing consumption and emissions, making it both economical and eco-friendly.

Laser cutting is the most commonly used method for processing acrylic due to its ability to deliver high precision and efficiency without direct contact with the material. For intricate or three-dimensional acrylic designs, laser cutting offers superior accuracy, multi-angle capability, and flexibility, making it a versatile and indispensable tool.

Disadvantages of Laser Cutting Acrylic

High Equipment Costs: The initial investment in a laser cutting machine is significant, and acrylic itself is relatively expensive. Additionally, the smoke generated during cutting necessitates a well-ventilated working environment, further increasing costs. For small-scale producers or beginners, these high equipment and operational costs can be a major barrier.

Requires Expertise and Experience: Operating a laser cutting machine demands specialized knowledge and experience. Without proper guidance, there is a risk of equipment damage or material waste. Incorrect temperature settings can also cause the material to burn. While the automation level of laser cutting machines is high, careful operation is still essential.

Unstable Productivity: The productivity of acrylic laser cutting can be inconsistent, as it depends on factors like the type of material, workpiece thickness, and cutting characteristics, which may lead to fluctuations in production efficiency.

Applications of Laser Cutting Acrylic

Laser cutting machines are widely used in processing acrylic (also known as plexiglass) due to their ability to efficiently handle complex shapes and deliver high-quality edges. This technology is suitable for various finely cut glass products and decorative applications across industries such as construction, automotive, furniture, and more. Laser-cut acrylic is commonly used to create architectural doors and windows, soundproof barriers, booths, advertising signs, exhibition structures, and light boxes.

Advertising Industry

Acrylic is a popular material for signage, light boxes, and display stands. Laser cutting enables the creation of custom shapes, sizes, and colors for advertising signs, offering great versatility in design and enhancing visual appeal.

Home Decor

With its lightweight, high transparency, and durability, acrylic is ideal for home products. Laser cutting allows the creation of uniquely designed items such as tableware, storage boxes, and more, catering to personalized needs.

Crafts and Artwork

Laser cutting facilitates the production of intricate acrylic crafts, including 3D engravings, business card holders, certificate bases, trophies, fishbowls and keychain, resulting in innovative and elegant creations.

Electronics Processing

High-precision laser cutting is used to manufacture acrylic components for electronic devices, such as casings and panels, ensuring accuracy and consistent quality.

Laser cutting technology allows acrylic materials to retain their inherent advantages while being shaped into diverse and complex designs, meeting the specific needs of various industries.

How to Use a CO2 Laser Cutting Machine for Acrylic

Cutting thin acrylic sheets with a CO2 laser cutter is typically straightforward and yields excellent results. However, cutting thicker acrylic or colored acrylic may result in uneven edges or whitening at the cut. By following key operational techniques, you can optimize cutting quality.

Step 1: Material and Equipment Selection

Acrylic Material:

Choose high-quality, uniformly dense acrylic sheets to avoid cracking or bubbling during cutting.

Recommended thickness: 2mm~6mm, which is within the capacity of most laser cutters and ensures good results.

Laser Cutter:

Use a CO2 laser cutter with a power rating of at least 80W.

Ensure the machine is equipped with a reliable cooling system and stable operation design.

Step 2: Parameter Settings

Before starting the cutting process, ensure the following configurations are properly set:

Material Fixation

Secure the acrylic sheet flatly on the worktable to prevent movement during the cutting process.

Software Configuration

Laser Power: Adjust the laser power based on the thickness of the acrylic sheet, typically maintaining it between 70% and 80%. Excessive power may scorch the material, while insufficient power may result in incomplete cuts.

Focus Adjustment: Set the focal point of the laser beam to align precisely with the cutting surface, based on the material thickness and selected laser power, to achieve optimal cutting results.

Cutting Speed: Adjust the speed according to the material’s thickness and type. For thicker acrylic sheets, use a slower cutting speed, typically around 100mm/min. For thinner sheets, a faster speed of approximately 350mm/min is suitable. Speeds that are too fast may lead to incomplete cuts, while speeds that are too slow may cause overheating.

Frequency (Pulse): For some laser machines, you may also need to set the laser emission frequency. Higher frequencies are generally ideal for more detailed work.

Testing and Optimization

Since actual cutting results are influenced by various factors—such as the type, thickness, and color of the acrylic, as well as the laser machine’s performance—always conduct a test cut to finalize the settings. Testing helps to optimize parameters and achieve the best cutting results.

Step 3: Cutting

Once all preparations are complete, and safety measures are confirmed, you can begin the cutting process.

Step 4: Post-Cutting Processing

After cutting, inspect the edges of the finished product. For certain applications, additional polishing or other treatments may be required to meet specific quality standards.

2024 The Best Laser Cutter for Acrylic

The laser cutter for acrylic and wood features a standard working area of 1300mm×900mm, with customizable options available. It offers a repeat positioning accuracy of ≤0.05mm and operates on an AC220V ± 5% / 50Hz power supply. This machine is ideal for cutting, trimming, engraving, hollowing, and perforating acrylic products, including plexiglass items, acrylic crafts, window lenses, transparent cases, advertising materials, packaging boxes, display stands, and crystal letters. It is widely used in industries such as advertising, packaging, and crafts.

Key Features

Focus Adjustment and Automatic Origin Setting:

Equipped with patented technology for quick laser focus adjustments and automatic origin setting. Standard industrial interfaces ensure powerful and stable performance.

Advanced DSP Control System:

Includes a professional motion control chip that supports continuous high-speed curve cutting and shortest path optimization, significantly improving productivity.

Flexible Power Options:

Can be configured with CO2 laser sources of varying power levels to meet specific application needs, ensuring an excellent cost-to-performance ratio.

High-Precision Structural Design:

Utilizes a three-way reflective system and linear guide rail structure to ensure smooth laser head movement, achieving precise engraving and cutting results.

Efficient CNC System:

Incorporates a CNC control system that supports large-format processing, fast processing speeds, streamlined workflows, and user-friendly operation.

This cutting-edge laser machine delivers outstanding performance and versatility, making it an essential tool for professional-grade acrylic processing.

How to Get the Acrylic Laser Cutting Machine Price?

We invite you to fill out the form or contact us directly with your detailed address, product specifications, and requirements. Based on your process needs, we will customize a suitable laser cutting machine for you and estimate the final cost of the acrylic laser cutting machine.

Please note that international shipping may incur customs duties and additional charges. To receive an accurate final price, don’t hesitate to reach out to us for a free quote.

In conclusion, laser cutting is an excellent method for working with acrylic sheets, offering high precision, clean edges, and the ability to create intricate designs. While it comes with some limitations, the benefits far outweigh the drawbacks, making it a preferred choice for many applications. The best laser cutter for acrylic provide perfect edge and accuracy, ensuring the best results for acrylic and wood cutting projects. Whether you’re in design, manufacturing, or crafting, acrylic CO2 laser cutting machine can elevate your production capabilities.