In modern automated manufacturing, collaborative robots are widely used to achieve faster and more precise operations. These robots are easy to program and can seamlessly switch between different tasks while maintaining the same level of accuracy. An automated laser cleaning machine works by combining a control system with cleaning trajectories and methods, supported by different cleaning media and processes to complete the task efficiently. The control system of an industrial laser cleaning robot enables intelligent automation, adjusting and optimizing operations based on workpiece shapes, contamination types, and cleaning requirements, which greatly improves efficiency and precision.

The robotic laser cleaning machine uses a focused laser beam to irradiate and ablate the surface of workpieces, efficiently removing stains and rust. It is particularly well-suited for cleaning parts with complex geometries and high precision requirements. Combining efficiency with accuracy, it cleans without damaging the surface and easily handles intricate designs, making it highly favored by manufacturers and widely applied across multiple industries. Although the initial investment is relatively high, laser cleaning offers superior efficiency and lower long-term costs compared to ultrasonic, chemical, or sandblasting methods.

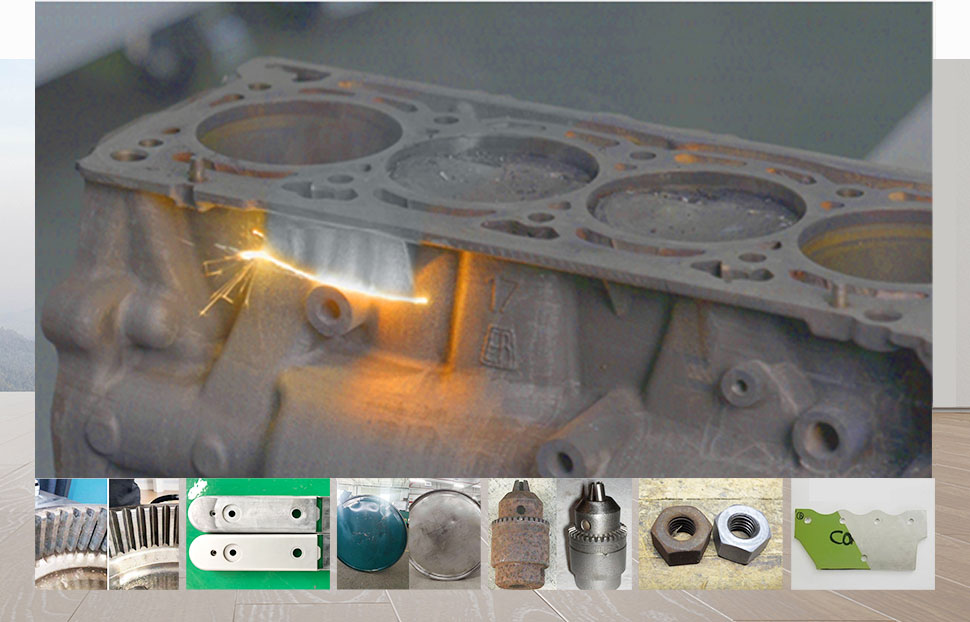

Application of Automatic Laser Cleaning Robot

The industrial laser cleaning robot is particularly well-suited for complex 3D components such as engine blocks, gearboxes, and wheels. By combining a robotic arm with our unique auto-focusing function, laser head positioning is greatly simplified, enabling precise cleaning and surface texturing.

1. Mold Cleaning

In manufacturing, mold cleanliness is critical to product quality and production efficiency. The laser cleaning robot quickly removes oil, rust, and residues from mold surfaces, improving cleaning efficiency while extending mold service life.

2. Precision Parts Cleaning

Traditional cleaning methods may risk damaging delicate components. In contrast, the laser cleaning robot effectively eliminates microscopic particles and contaminants without harming the surface, ensuring part accuracy and performance.

3. Artwork & Cultural Heritage Preservation

Laser cleaning provides a gentle yet effective solution for removing stains and dust from artworks and historical artifacts. It preserves the original texture and luster of materials, making it an essential tool in restoration and conservation.

4. Aerospace Applications

The aerospace industry demands exceptional cleanliness standards. The laser cleaning robot efficiently removes oxides, coatings, and oils from metal surfaces, ensuring components meet stringent requirements and contributing to flight safety.

Why Choose Automated Laser Cleaning Machine?

1. Precision & Controlled Cleaning

The laser cleaning machine offers adjustable laser energy and cleaning speed, enabling precise parameter control tailored to both the base material and contaminants. This makes it ideal for delicate instruments and precision components.

2. Flexible & Efficient

By fine-tuning laser power, frequency, aperture, and focal length, the cleaning range and intensity can be accurately controlled. In addition to cleaning, the process can also modify surface roughness to improve adhesion, boosting efficiency while reducing operational costs.

3. Green & Eco-Friendly

Laser cleaning requires no chemical solvents, eliminating the environmental hazards associated with chemical cleaning methods such as acid pickling or phosphate. It introduces a cleaner, safer, and more sustainable approach to industrial cleaning.

4. Easy Waste Management

Contaminants removed by the laser are converted into small, solid particles that are easy to collect and dispose of. This prevents secondary pollution and aligns with the growing demand for sustainable, green cleaning solutions.

5. Remote & Intelligent Operation

As a non-contact cleaning method, laser technology can be delivered via optical fibers and integrated with robots or manipulators to perform remote cleaning—reaching areas that traditional methods cannot. With automation and smart control systems, it adapts seamlessly to high-volume, large-scale production environments, enhancing both productivity and quality.

6. Versatility across Materials & Contaminants

The system is effective on a wide range of materials and contaminant types, achieving exceptional cleanliness. Pulsed lasers are particularly suitable for removing oxide layers from titanium alloys, cleaning stainless steel weld seams and spots, and performing pre- and post-weld surface treatments on precision parts—representing a new frontier in surface engineering applications.

Industrial Robot Laser Cleaning Machine

Laser power: 200W, 300W, and 500W available.

Cleaning efficiency: 3~6 ㎡/hour.

Efficient & Eco-Friendly Cleaning

The laser cleaning machine effectively removes rust, paint, oil, grease, and weld residues from surfaces. Compared with traditional cleaning methods, it offers higher efficiency, zero pollution, no damage to the substrate, and easier operation.

Multi-Functional Applications

Capable of removing rust, paint, coatings, oxides, and adhesives from metal surfaces, while also suitable for cleaning non-metal materials such as stone, wood, and sculptures.

Non-Contact Cleaning

Both pulsed and continuous laser cleaning machines use a focused laser beam to remove contaminants without physical contact. The ultra-short laser interaction time avoids surface deformation and protects the integrity of the base material.

Eco-Friendly & Pollution-Free

No chemicals are required and no secondary waste is produced, ensuring a safe, sustainable, and environmentally friendly cleaning process.

Low Maintenance Costs

Operation only requires routine lens cleaning and occasional replacement, keeping maintenance costs minimal.

Why Choose Dapeng Laser’s Industrial Laser Cleaning Robotic?

1. Easy Operation

The fiber laser cleaning machine features a simple structure, consisting of the laser cleaning system, workbench, and a 6-axis laser arm. Cleaning parameters can be easily adjusted, and the visualized cleaning process allows immediate detection and re-cleaning of any contaminated areas.

2. Customizable Automation

With automated and intelligent functions, the system ensures efficient and stable operation while reducing manual intervention. By adding industrial lenses, it can achieve automatic positioning and automatic contaminant removal.

3. Time-Saving

Compared with traditional cleaning methods, laser cleaning quickly and effectively removes surface contaminants. Even thin paint layers can be cleaned in a single pass, eliminating the need for re-cleaning and saving both time and labor costs.

Robot Laser Cleaning Machine Price

With the growing adoption of laser cleaning technology in the mold industry, demand for mold cleaning machines has steadily increased. However, many companies often notice a wide price range when purchasing seemingly similar machines.

A laser cleaning system represents a deep integration of laser technology and industrial robotics. It typically includes a laser source, robotic arm, laser cleaning head, control system, chiller, and various accessories. During automated cleaning, the system enables precise and consistent operations.

1. Level of Automation

- Basic Automatic Laser Cleaning Machine: Priced around ¥10,000, suitable for small-batch cleaning where manual involvement is higher.

- Mid-Range Automatic Laser Cleaning Machine: Typically ¥20,000–30,000, meeting the daily needs of medium-capacity manufacturers.

- High-End Fully Automatic Laser Cleaning Robot: Prices range from ¥30,000–50,000, equipped with intelligent controls, robotic arms, and tracking/positioning systems. The final cost depends on the base laser system and the customization of additional modules.

Automatic Laser Cleaning Systems

Laser parameters such as power and scanning width directly affect cost. Expanding the working area requires higher investment. Additional features like automation setups and custom configurations also increase the price.

Laser cleaning machines can collaborate with robots, rotary fixtures, and clamps for fully automated cleaning. The more customized the system, the higher the investment—but it significantly reduces manual intervention, making it ideal for large-scale production.

2. Cleaning Size & Laser Power

Larger molds require bigger cleaning chambers and higher laser power, which naturally increases equipment costs. High-power laser sources and larger systems are especially necessary for large injection molds or die-casting molds.

3. Cleaning Method & Process

Different cleaning processes—such as pulsed or continuous lasers, or integration with rotary tables and robotic arms—directly affect the system structure and cost. The higher the required cleaning precision, the more complex the process configuration, and consequently, the higher the price.

4. Functional Features & Customization

Some companies require additional capabilities such as intelligent monitoring, automatic recognition, fine oxide layer removal, or weld seam treatment. While these custom features enhance cleaning efficiency and stability, they also significantly increase equipment costs.

5. Brand & After-Sales Service

Well-known brands often offer greater stability, longer laser source lifespan, and more reliable after-sales support. As a result, their prices tend to be higher. For businesses focused on long-term operating costs, brand reputation and service quality are important investment considerations.

✅ Summary

The price differences of mold cleaning machines mainly depend on factors such as cleaning requirements, equipment configuration, cleaning process, level of automation, and brand/service quality. When selecting a system, companies should not focus solely on price. Instead, they should consider their production capacity, cleaning frequency, and long-term maintenance costs to make a comprehensive evaluation and choose the most suitable solution.

Is Investing in a Robot Laser Cleaning System Worth It?

The value of investing in industrial laser cleaning equipment depends on your specific needs. If your budget allows, a fully automated laser cleaning machine is a great choice. For limited budgets, a compact, mobile laser cleaning system can be a more economical option—meeting short-term cleaning needs while leaving the option to upgrade to a larger system later.

Investing in a robot laser cleaning machine offers significant long-term benefits, including higher precision, consistent cleaning quality, and reduced labor costs. While the initial robot laser cleaning machine cost may seem substantial, the improved efficiency, minimized maintenance, and versatility across different industrial applications make it a worthwhile investment for manufacturers seeking to modernize their cleaning processes and maintain competitive production standards.