High Power Fiber Laser Cutting Machine for Thick Metal Sheet

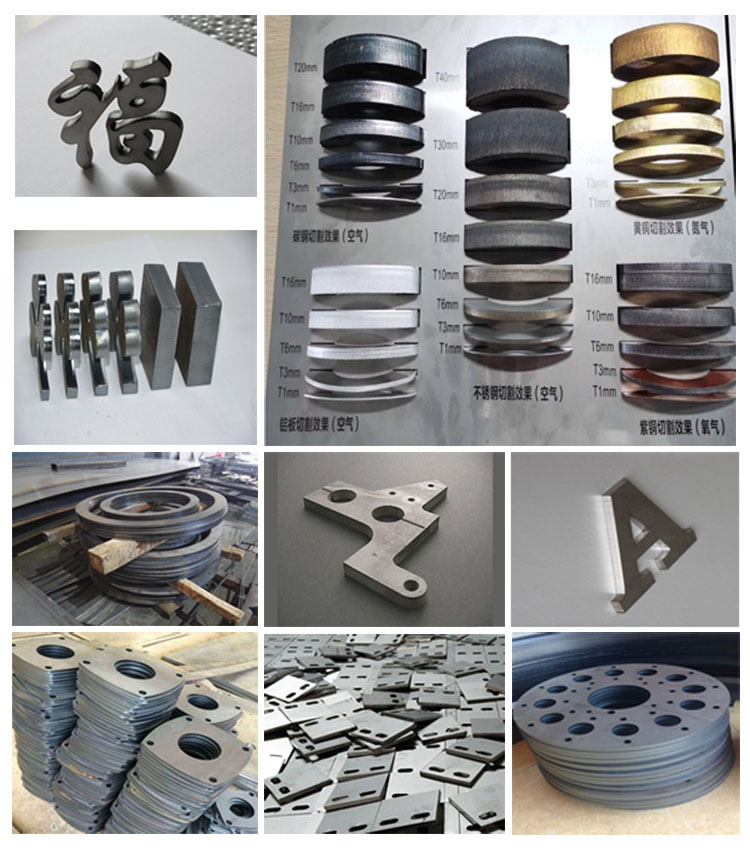

This CNC fiber laser cutting machine for metal is specifically engineered for processing a wide range of metal plates, including but not limited to stainless steel, galvanized steel, carbon steel, aluminum, alloy, brass, bronze, iron, and copper.

Its capability extends across various thicknesses, allowing for precision cutting of thin and thick metal materials. Whether dealing with intricate designs or bulk production, this High Power CNC laser cutting machine for metal offers consistent and accurate results across diverse metal types and thicknesses. It is an ideal solution for industries requiring robust cutting capabilities for thick metal sheets in applications like manufacturing, construction, and heavy machinery production.

The industrial metal laser cutting machine is designed for efficient material processing through a versatile platform that facilitates quick and automated exchange of materials. The exchange platform feature enhances productivity by allowing seamless transitions between different workpieces, optimizing workflow in a user-friendly manner.

Product Details:

- Easy to operate and maintain

The system is highly integrated, easy to operate and maintain, and can meet 24-hour production needs - Our laser cutting head has the function of stretching up and down, which can automatically adjust the height of the laser cutting head according to the thickness of the plate and the height of the cutting table.

- Any graphics can be processed

It has good processing flexibility and can process any graphics. It can cut any hardness materials such as pipes, special-shaped materials, steel plates, stainless steel, aluminum alloy plates, and hard alloys without deformation. - Cast iron bed

Excellent iubricating properties, lower heat sensitivity, higher strength and hardness. Effectively reduce equipment usage loss and bed vibration processing error. - Security

Optional Fully enclosed structure, visible protection window, standard protection system.

Application

1. Application Industries: Widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

2. Application Materials: Suitable for metal cutting with Stainless Steel Sheet, Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Iron Plate, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.