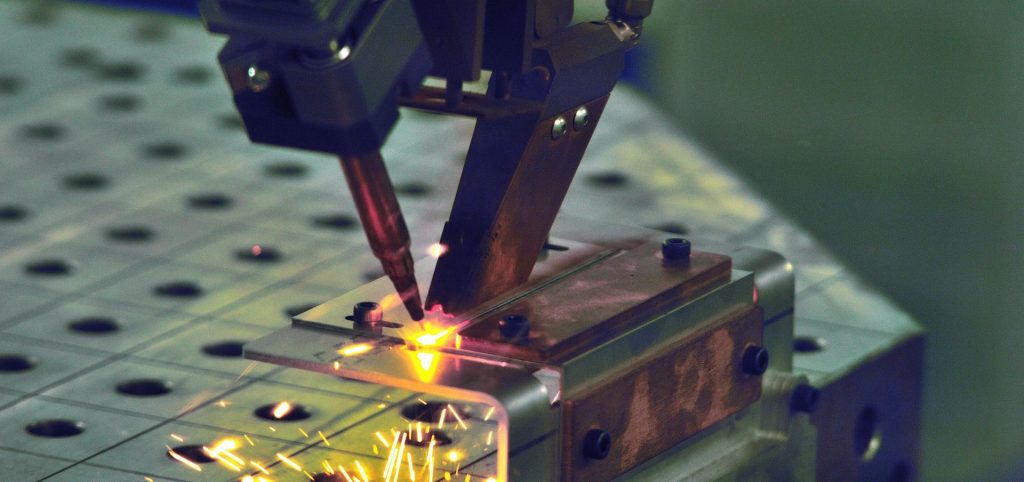

Laser engraving machines have become a ubiquitous tool in modern manufacturing, leaving their mark on countless products in our daily lives. From mobile phones, earphones, and chargers to power strips, remote controls, and elderly-friendly phones, their applications are endless. Logos, patterns, models, CE marks, serial numbers, and customized designs on items like USB drives, Coke cans, and mobile phone cases are all examples of laser engraving in action. However, depending on the material—metal or plastic—different types of laser engraving machines are used, each with unique capabilities and effects.

Metal Laser Engraving Machines

Metal laser engraving machines are typically fiber laser engraving machines, often referred to as “red light machines” due to the red laser light they emit. Operating at a wavelength of 1064nm, these machines excel in marking metals and certain non-metal materials. They produce clear, precise results on metal surfaces, capable of creating black-and-white markings by adjusting the laser’s power and parameters.

While fiber laser machines can also engrave plastics, the results are less ideal. Plastics, being heat-sensitive materials, often exhibit raised textures and less refined markings when processed with fiber lasers. For applications without stringent marking requirements, fiber lasers can suffice due to their affordability. However, for high-quality plastic engraving, a different machine is preferred.

Plastic Laser Engraving Machines

Plastic laser engraving machines utilize ultraviolet (UV) laser source. These are known as “purple light machines” because of the purple light they emit, with a wavelength of 355nm. This shorter wavelength allows UV lasers to be absorbed by a wider range of materials, making them ideal for engraving plastics. The fine laser spots create detailed, high-quality markings without leaving a tactile texture.

UV laser engraving machine use a “cold processing” method, which minimizes heat damage and ensures a smooth, refined finish. This contrasts with the “hot processing” method of fiber lasers, which can cause more noticeable heat effects on materials like plastic.

While fiber laser machines can mark plastics, the results are suboptimal. Conversely, UV laser machines can mark metals, but they typically operate at lower power levels (e.g., 3W), making them less efficient for metal applications. Using UV lasers on metals can strain the laser source and reduce its lifespan.

Choosing the Right Laser Engraving Machine

When selecting a laser engraving machine, it’s essential to consider the material and marking requirements of your product. Fiber lasers are cost-effective and suitable for metal engraving and basic plastic applications, while UV lasers are better for high-quality plastic engraving and intricate designs. Most manufacturers offer sample testing services, allowing you to evaluate the engraving results before making a decision.

In conclusion, understanding the differences between metal and plastic laser engraving machines helps ensure the best results for your specific application. Both machines have their strengths and are integral to achieving precision and quality in modern manufacturing.