In the field of industrial manufacturing and surface treatment, removing metal coatings has long been a technical challenge. Whether dealing with rust, grease, paint, or oxide layers, traditional cleaning methods often suffer from low efficiency, high costs, and the risk of damaging the base material. When it comes to maintaining the performance, appearance, and structural integrity of metals, understanding how to remove oxide from metal is essential. Traditional methods such as mechanical polishing and chemical etching have long been used, while electrochemical removal offers more controlled results. However, advanced laser cleaning technology is emerging as a precise, efficient, and eco-friendly solution for removing oxide layers from titanium surfaces.

Why Need to Remove Titanium Oxide Layer?

Titanium alloys, prized for their light weight, high strength, exceptional corrosion resistance, excellent performance across extreme temperatures, non-magnetic properties, and outstanding biocompatibility, have shown immense potential in high-end sectors such as aerospace, defense, and medical technology.

However, during melting, machining, and service, a dense and stable oxide film readily forms on the titanium alloy surface. This oxide layer can degrade the material’s mechanical properties, increase potential safety risks in use, and dull its metallic luster—compromising both the visual quality and commercial value of the product.

Laser removing oxide coating and other surface contaminants (such as grease, dirt, and rust) from titanium creates a clean, smooth, and uniform substrate. This not only enhances the adhesion of subsequent coatings but also ensures a superior, aesthetically pleasing, and professional finish for the final product.

How to Remove Oxide from Titanium: a Challenge to Remove Oxide

Common methods for removing oxide layers from titanium alloys include mechanical polishing, chemical etching, and electrochemical processes.

Mechanical methods

Such as sandblasting, grinding, and polishing—can effectively remove surface oxides. These techniques are relatively low-cost and require no chemical reagents. However, they may damage surface flatness and increase roughness.

Chemical etching

Chemical etching involves dissolving the oxide layer using acid pickling solutions, typically a mixture of hydrofluoric acid and nitric acid. This approach offers rapid processing, is suitable for large-area treatment, and can also remove surface stains for a smoother finish. On the downside, it requires chemical preparation and generates large volumes of wastewater, posing significant environmental pollution risks.

Electrochemical

Electrochemical removal uses electrolytic action to strip the oxide layer from titanium alloys. It allows precise control over removal depth and area with minimal impact on the underlying surface. However, this method comes with high equipment costs, complex operation that requires skilled technicians, and additional expenses for chemical waste treatment.

Laser Cleaning: A Precise, Efficient, and Eco-Friendly Solution for Titanium Surface Treatment

Laser cleaning technology employs high-frequency, high-energy laser pulses to irradiate the surface of a workpiece. The coating layer instantly absorbs the focused laser energy, causing surface contaminants such as oil, rust, or paint to vaporize or peel off within microseconds. This enables the rapid and effective removal of surface deposits or coatings. With properly tuned parameters, the ultra-short laser pulses will not damage the underlying metal substrate.

Titanium and its alloys, known for their excellent corrosion resistance and high strength-to-weight ratio, are widely used in medical devices, machine components, and aerospace applications. However, their surfaces are prone to unevenly distributed oxide scales. Mechanical grinding struggles to treat complex geometries, while chemical etching poses challenges such as high gas emissions, difficult liquid waste management, and risks of over-corrosion or perforation.

Laser cleaning can effectively remove oxide layers 1–20μm thick, avoiding the environmental and material damage associated with chemical treatments. By precisely adjusting laser parameters, oxide films—such as titanium oxide—can be eliminated without harming the base material, restoring a clean, bright titanium surface ready for engineering reuse. This makes laser cleaning an ideal alternative to traditional etching and grinding methods.

Why Choose Laser Cleaning Titanium Dioxide?

High Efficiency

Laser cleaning systems can rapidly remove contaminants such as oil, rust, and paint from automotive metal parts, significantly improving cleaning speed. They support continuous or pulsed operation modes, making them ideal for batch automated processing, shortening cycle times and boosting production efficiency.

Environmentally Friendly

The process requires no chemical reagents and produces no wastewater or exhaust emissions. Particles and fumes generated during cleaning are captured and treated via integrated dust collection systems. Additionally, laser cleaning consumes relatively low energy, aligning with green manufacturing trends.

Precision

The laser beam offers high-precision targeting and energy control, enabling effective cleaning of titanium alloy parts with complex structures and fine features. This makes it especially suitable for industries like aerospace, electronics, and medical devices, where surface quality is critical.

High Automation

Laser cleaning equipment can be integrated with robots or automated production lines to achieve fully automated cleaning control. Automation enhances cleaning consistency and efficiency while reducing labor costs.

Versatility

Laser cleaning is applicable to various metal materials, including steel, aluminum alloys, and titanium alloys. Whether dealing with flat surfaces, curves, or intricate shapes, laser cleaning systems handle them with ease.

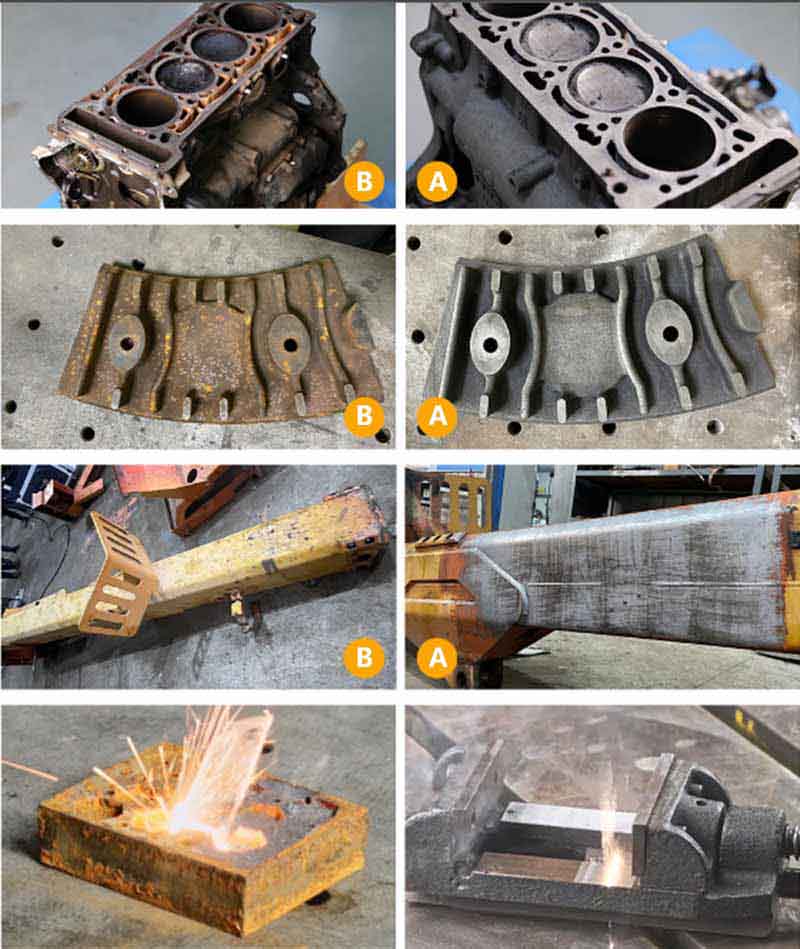

Application of Laser Cleaning of Oxidized Layer on Titanium

Laser cleaning is an effective method for removing oxide layers and contaminants from titanium and titanium alloy surfaces.

1. Surface Cleaning of Titanium Alloy Components

In high-end manufacturing fields such as aerospace and medical devices, titanium alloy parts often carry oxide scales, trace oils, or dust that can affect subsequent processing accuracy and service performance. Laser cleaning efficiently removes these contaminants, especially on complex geometries and fine features, ensuring stable surface quality and improving overall assembly performance and reliability.

2. Laser Cleaning of Titanium Alloy Automotive Parts

Titanium alloys are widely used in critical automotive components like engines and chassis, where surface oil, rust, and other impurities can impact performance and lifespan. Laser cleaning provides a high-efficiency, precise, and non-contact cleaning solution that significantly enhances the durability and reliability of these parts.

3. Pre-Welding Treatment of Titanium Materials

Removing oxide layers and surface contaminants from the weld zone is crucial before titanium alloy welding to prevent defects and maintain joint performance. Laser cleaning allows precise control of the cleaning area and depth, quickly stripping oxide films without damaging the substrate, effectively improving weld strength and consistency. It is a key step in high-quality titanium welding processes.

4. Surface Refinement of Titanium Components

Titanium surfaces may develop discoloration, stains, or dullness after heat treatment, storage, or prolonged use. Laser cleaning restores the original appearance and enhances metallic luster, improving product aesthetics. This is especially beneficial for medical devices, titanium jewelry, and high-end structural components, as the process does not cause mechanical abrasion or thermal damage to the substrate.

Fiber Laser Cleaning Rust Removal Machine

Laser cleaning, as a pollution-free, consumable-free, and fully visualized and controllable industrial cleaning technology, shines in rust removal, paint stripping, mold cleaning, and metal surface processing. It is the ideal choice for manufacturing enterprises upgrading their industrial structure.

Using advanced laser technology, this equipment rapidly removes surface oxides, oils, coatings, and other contaminants, making it especially suitable for cleaning and pretreatment of titanium alloys, steel, aluminum, and other materials. Featuring wide cleaning widths and all-weather operational capability, combined with intelligent control and ergonomic design, it represents a green cleaning solution for modern manufacturing.

Key Features:

Renowned Laser Brands: Equipped with stable, energy-efficient, and low-maintenance lasers from top brands such as Raycus and MAX, suitable for diverse working conditions.

Intelligent Control Panel: Full touchscreen operation supporting multiple languages, with a built-in process library for easy, repeatable settings.

Integrated Water-Cooled Cabinet: Industrial-grade sheet metal structure ensures durability and efficient heat dissipation, ideal for high-intensity, large-scale production.

Ergonomic Design: Well-structured chassis allows easy maneuvering, deployment, and onsite operation.

High Flexibility and Efficiency: Non-contact 360° cleaning unrestricted by space or position, suitable for diverse industrial cleaning scenarios.

Wide Cleaning Area: Cleaning width increased by 130%, with efficiency gains between 37% and 69%, supporting 24/7 continuous operation.

Dual Swing Smart Head: Supports seven scan modes, enabling automatic reciprocation, rotation, and cross-beam output for uniform cleaning and enhanced surface appearance.

Smart Remote Connectivity: Mobile app support for one-touch operation and real-time parameter adjustment, breaking distance barriers for efficient remote management.

Multi-Scenario Applications: Ideal for paint removal, pretreatment before coating, aerospace component cleaning, oxide removal before and after welding, oil and residue cleaning, and more.

How to Use Laser Cleaning Machine Removing Oxide Coating from Titanium?

- Install the laser cleaning equipment in a well-ventilated and safe area.

- Wear protective goggles and strictly follow all safety procedures.

- Set the appropriate laser parameters based on the condition of the oxide layer on the titanium surface.

- Hold the handheld laser head firmly and aim it at the oxidized area.

- Move the laser beam slowly and evenly to cover the cleaning surface. The laser efficiently removes the oxide layer without damaging the metal substrate.

- Inspect the cleaned area; if oxide residue remains, repeat the process as needed.

Laser cleaning requires no chemicals and produces no secondary pollution. It is highly efficient and suitable for cleaning complex structures and hard-to-reach areas, applicable for both small precision cleaning and large-scale surface treatment.

Post-Cleaning Storage of Titanium Metal

- After each cleaning, rinse the titanium surface with deionized water and thoroughly dry it to prevent subsequent reactions.

- It is recommended to apply a protective coating, such as paint, anodizing, or a clear sealant, to isolate the surface from moisture and air.

- Store titanium materials in a dry and secure environment whenever possible.

In summary, removing oxide coating from titanium is a critical step to ensure the metal’s optimal performance. While traditional methods like mechanical polishing and chemical treatments have their place, laser cleaning machine offers a modern alternative that is both precise and environmentally friendly. By adopting advanced laser cleaning machines, industries can achieve efficient oxide removal with minimal surface damage, improving the quality and reliability of titanium components across aerospace, medical, and manufacturing sectors.