In industrial manufacturing, product packaging and information marking are essential for efficiency and traceability. From signage, trademarks, and company logos to barcodes, QR codes, production dates, serial numbers, and alphanumeric text, accurate and efficient marking is vital for mass production.

Industrial laser marking machine offers high precision, non-contact processing, and permanent marks, making them ideal for handling complex engraving tasks. These machines help manufacturers improve marking quality and production efficiency while meeting the increasing demands for precision, traceability, and customization in modern manufacturing.

Can the Laser Marking Machine Achieve Industrial Mass Production?

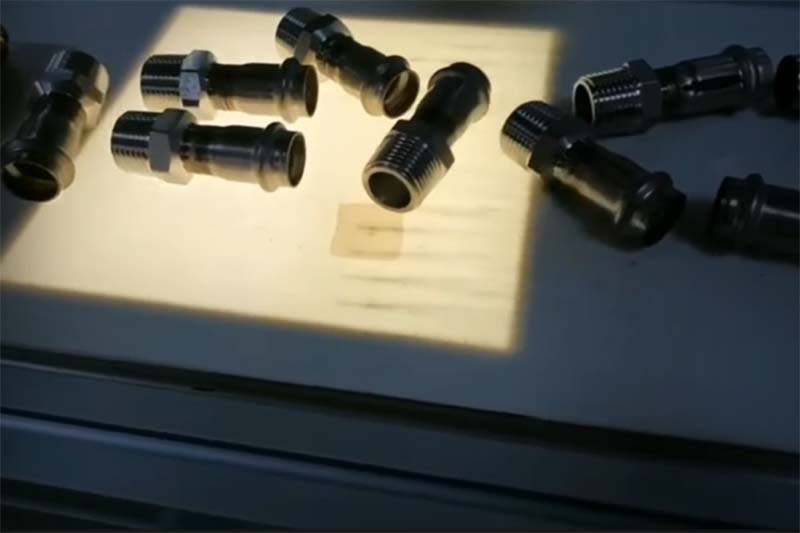

Yes, laser marking machines are highly suitable for industrial mass production. They are widely recognized for their high processing efficiency, broad material compatibility, and superior marking quality. Laser marking is a non-contact process, meaning there is no mechanical force exerted on the workpiece. This results in no physical wear, minimal thermal impact, and preservation of the original precision of the parts. Additionally, laser marking is compatible with a wide range of materials and can produce highly detailed and durable marks on various surfaces.

Automatic laser marking for industry is designed with specialized mechanical, electrical, and software interfaces, allowing seamless integration with the customer’s existing production equipment and assembly lines. These systems can be customized to meet specific production and process requirements, with tailored auxiliary function modules developed to better align with customer needs and deliver optimized marking solutions.

When integrated into a production line, industrial laser marking machines offer capabilities such as synchronized material feeding, centralized conveying, rapid positioning, intelligent marking, automatic unloading, and automated stacking. This enables fully automated marking operations on products of varying shapes and sizes, meeting the demands for high-speed production, smart marking, and precise positioning in modern industrial environments.

Why Use Laser Marking for Mass Production?

1. High Processing Efficiency

Laser marking offers exceptionally fast processing speeds, capable of completing engraving or marking tasks within seconds. This significantly boosts output per unit of time, making it ideal for continuous operations on production lines and fulfilling the high-throughput demands of modern manufacturing.

2. Clear and Durable Markings

Laser-marked patterns feature high resolution, permanence, and strong resistance to wear and fading. This makes them ideal for marking critical information such as serial numbers, QR codes, and production batches—supporting product traceability, quality control, and anti-counterfeiting efforts.

3. No Consumables, Low Maintenance

The laser marking process requires no ink, labels, or other consumables, and operates without physical contact with the workpiece. This reduces material waste and mechanical wear, leading to lower maintenance costs and making it well-suited for long-term, high-intensity industrial use.

4. Widely Material Compatibility

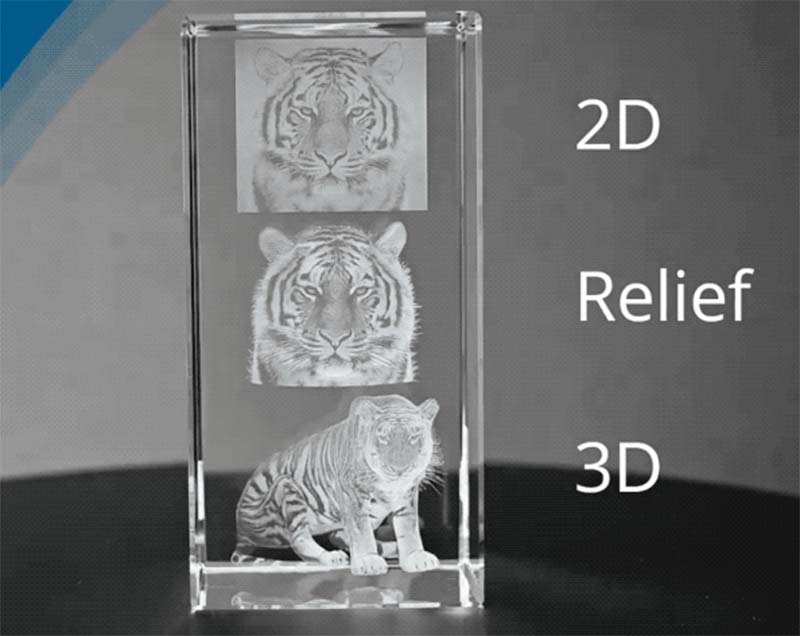

Laser marking machines can handle a wide variety of materials, including metals, plastics, ceramics, and glass. With advanced 3D marking capabilities, they can also mark curved or irregular surfaces with precision, enabling customization and meeting the complex structural requirements of diverse products.

5. Easy Integration with Automation Systems

Laser marking equipment is easily integrated into automated production systems, including robotic arms, vision inspection systems, and conveyor lines. This facilitates unattended, continuous processing and enhances overall productivity and manufacturing intelligence.

More Powerful Functions of Laser Marking on Production Lines

1. Flexible Handling of Varying Heights and Irregular Workpieces

Laser marking machines—especially those equipped with advanced 3D marking technology—are capable of rapidly adjusting laser focal length and beam path. This enables precise and efficient marking on workpieces of varying heights and complex geometries, including cylindrical, curved, and irregularly shaped parts. Such adaptability significantly enhances production flexibility and efficiency.

2. Multi-Color and Grayscale Marking Capabilities

Through precise control of laser parameters and defocusing distances, laser marking machines can produce vivid multi-color or grayscale patterns on metal surfaces. Whether it’s deep black marking on anodized aluminum or full-color effects on metallic finishes, this technology meets both the functional and aesthetic demands of high-end products.

3. Versatile Integration and Broad Industry Applications

Laser marking machines offer outstanding versatility, capable of marking flat surfaces, curved components, and irregular shapes with equal ease. They are widely used across industries such as automotive, electronics, medical devices, and food packaging. With broad material compatibility and flexible system integration, laser marking provides an ideal solution for scalable, automated production environments.

What Are The Industrial Production Applications of Laser Marking?

1. Electronics Manufacturing

In integrated circuit (IC) production, laser marking machines efficiently mark chip surfaces with batch numbers, QR codes, and other identifiers—enabling nanometer-level traceability and full quality control. For miniature components such as resistors and capacitors, UV laser marking offers non-contact, permanent, and high-precision marking, perfectly suited for the high-speed demands of SMT (Surface Mount Technology) production lines.

2. 3C Product Manufacturing

Laser marking is widely used in the 3C (Computer, Communication, Consumer Electronics) industry for tasks like engraving logos on metal phone casings and coding on flexible printed circuit boards. UV lasers, known for their precision and speed, ensure all markings are sharp, durable, and aesthetically pleasing—meeting both appearance and efficiency standards in high-volume consumer electronics manufacturing.

3. Automotive Industry

Laser marking plays a critical role in marking key automotive components such as engines, frames, and tires with serial numbers, batch codes, and safety markings. This permanent, high-precision marking supports full lifecycle management and traceability of auto parts, enhancing quality control throughout the manufacturing and post-sales process.

4. Food and Beverage Packaging

Laser marking is used to mark expiration dates, batch numbers, and anti-counterfeit codes on product packaging. Its non-contact, clean, and chemical-free process ensures food safety and hygiene while improving production efficiency and eliminating pollution risks associated with traditional ink printing. Clear and readable markings are also achievable on transparent or semi-transparent packaging materials.

5. Medical Devices

Laser marking provides high-precision, permanent identification on surgical instruments, medical consumables, and biological sample tubes. These durable markings enhance the traceability of instruments and ensure accurate sample identification—contributing to improved patient safety and more efficient medical inventory management.

6. Mold Manufacturing

In mold production, laser marking machines replace traditional nameplate labels by engraving batch numbers, material information, and embedded QR codes directly onto mold steel surfaces. This enables full lifecycle data management for molds. The technology is also widely used for anti-counterfeit marking on injection molds and die-casting molds, as well as in industries such as medical devices, jewelry, and construction materials.

Online Flying Laser Marking Machine for Mass Production

The Flying Laser Marking Machine is a high-performance marking solution specifically engineered for high-speed, continuous-flow production lines. Its core advantage lies in its ability to perform precise, uninterrupted marking on moving workpieces, significantly boosting production efficiency. It is ideal for large-scale, fast-paced automated manufacturing environments.

Energy-Efficient and Compact Design

Featuring a streamlined, compact structure, the system is air-cooled for low energy consumption and stable long-term operation. All key components are imported to ensure superior performance and extended service life. The optical system is fully sealed and includes a red light preview for easy alignment. The design combines functionality with a modern industrial aesthetic.

High Precision Marking with Fine Detail

With excellent beam quality and high photoelectric conversion efficiency, the machine delivers ultra-fine marking lines and smaller laser spots. It is perfectly suited for precision marking applications where exceptional detail and marking quality are critical.

Versatile and Highly Compatible

The system supports a wide range of marking formats, including barcodes, QR codes, text, graphics, serial numbers, as well as deep engraving, black marking, and rotary marking. It is compatible with major graphic file formats such as PLT, AI, DXF, BMP, and JPG.

Customizable for Industry Production Needs

Tailored customization options are available to meet diverse industrial requirements. Marking content, processing methods, and auxiliary features can be flexibly configured to adapt to automated lines, special materials, or complex component marking.

Not only highly efficient, the machine also delivers exceptional marking precision. Powered by advanced laser control technology, it achieves micron-level clarity, ensuring every product is marked with perfect accuracy. This capability is especially critical in industries with stringent marking requirements, such as electronic components, medical devices, and food packaging.

With its high speed, precision, and stable performance, the flying laser marking machine has become an essential tool for modern manufacturing—enhancing productivity, ensuring quality, and streamlining production processes. Laser marking technology is emerging as a new benchmark in smart manufacturing, driving the industry toward greater automation and sustainability.

Conclusion:

Explore our comprehensive industrial marking solutions, designed to meet the diverse needs of various industrial applications. Whether engraving on paper, plastic, metal, or non-metal materials, our industrial laser marking systems deliver precise and reliable results tailored to industry-specific requirements. As a leader in the laser technology sector, Dapeng Laser is dedicated to the research, development, and manufacturing of advanced laser equipment—providing end-to-end laser marking on production lines and empowering customers to upgrade and modernize their manufacturing capabilities.