In today’s manufacturing and restoration industries, maintaining surface integrity while removing contaminants is a top priority, especially when dealing with delicate materials. Pulsed laser cleaning has emerged as the ideal solution for sensitive surface applications, offering precision without damaging the underlying material. In this blog post, we’ll delve into the benefits of laser cleaning sensitive surface, explore its applications across a variety of sensitive materials.

Can Laser Cleaning for Sensitive Surface?

Of course, laser cleaning technology refers to the use of high-energy laser beams to irradiate the surface of the workpiece, so that the surface of the dirt, rust spots or coatings undergo instantaneous evaporation or stripping, high-speed and effective removal of the cleaning object surface attachments or surface coatings. By controlling the system the laser can precisely target and vaporize the stain without damaging the underlying material. The process is tightly controlled and the power and duration of the laser can be adjusted according to the material and type of stain.

Laser cleaning is non-contact, which makes it very safe to clean precision workpieces or their fine parts to ensure their accuracy. Therefore, laser cleaning has unique advantages in the industry of cleaning precision instruments and sensitive materials.

Features of Laser Cleaning

- Efficiency: Laser cleaning operates at high speeds, enabling large mold surfaces to be cleaned in a short time.

- Precision: The focused laser beam allows for precise control of the cleaning area, avoiding damage to the mold’s base material.

- Eco-friendliness: The laser cleaning process requires no chemical agents or water, significantly reducing environmental pollution.

- Automation and Intelligence: With ongoing advancements in technology, laser cleaning equipment is gradually becoming more automated and intelligent, further enhancing cleaning efficiency and accuracy.

Laser cleaning offers great advantages for various materials. Its precision, efficiency, and eco-friendly nature make it a superior option compared to traditional methods. However, while large manufacturers may afford the high initial costs, laser cleaning for surface treatment may not be a cost-effective solution for small business owners providing surface cleaning and preparation services.

Why Use Laser Cleaning Sensitive Material?

Sensitive surface cleaning by laser, the parameters must be set according to the physical and chemical properties of the material. For example, heat-sensitive substances like synthetic materials, plastics, and rubber may melt, deform, or experience color degradation if too much heat accumulates during laser application. Similarly, certain polymers, coatings, and metal alloys can undergo thermal decomposition, melting, or oxidation when exposed to excessive laser energy, leading to burn marks or color changes on the material’s surface.

Laser cleaning is gaining popularity in industrial cleaning due to its efficiency, eco-friendliness, and non-contact approach to the substrate.

However, when using laser cleaning, it’s crucial to precisely control parameters such as laser wavelength, power, energy density, pulse duration, and frequency to avoid damage to the material.

Why Use Pulsed Laser Cleaning for Sensitive Materials?

Pulsed laser cleaning excels in sensitive materials due to its high level of protection for the substrate and the precise control it offers during the cleaning process.

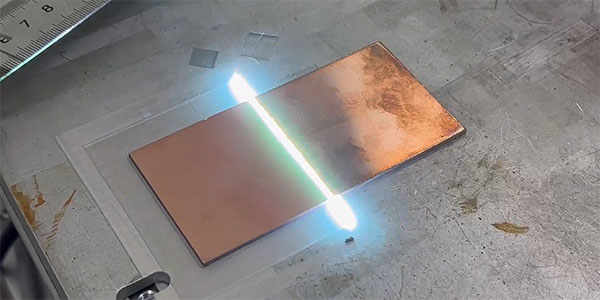

Wavelength Selectivity: By selecting the appropriate wavelength, the laser’s energy can be absorbed mainly by the surface contaminants rather than the underlying material. For instance, specific infrared lasers can effectively remove rust or oxide layers from metal surfaces without damaging the metal itself.

Application of Ultra-Short Pulses: Using ultra-short pulses at the nanosecond, picosecond, or femtosecond level allows for rapid energy release, causing contaminants to heat up, vaporize, or ablate quickly. The base material remains unaffected due to the extremely short heat diffusion time.

Precise Adjustment of Energy Density and Repetition Rate: By fine-tuning the laser’s energy density and pulse repetition rate, a balance can be struck between removing contaminants and preserving the substrate, ensuring effective cleaning without damaging the base material.

Non-Thermal Cleaning Mechanisms: Techniques like photo-induced shockwaves, mechanical effects, and plasma formation can physically remove contaminants without relying on high temperatures, minimizing thermal damage to the substrate.

Plasma Shielding’s Self-Limiting Effect: Once plasma is formed by the contaminants absorbing laser energy, it can absorb or reflect subsequent laser pulses. This self-limiting effect helps prevent over-cleaning and protects the base material.

Precision Focusing and Scanning Control: Advanced focusing systems and programmable scanning paths, speed, and power control allow for precise cleaning on complex geometries and intricate details, avoiding unnecessary damage.

Minimized Heat-Affected Zones: The extremely short laser pulses prevent heat from spreading into the substrate, keeping the heat-affected zone confined to the contaminant layer and avoiding thermal damage to the base material.

Applications of Laser Cleaning for Fragile Surfaces

Laser cleaning technology is widely used in industries such as microelectronics, rail transportation, aerospace, shipping, and automotive manufacturing. Common applications include the removal of particle contaminants, rust, paint, oil stains, and oxidation layers.

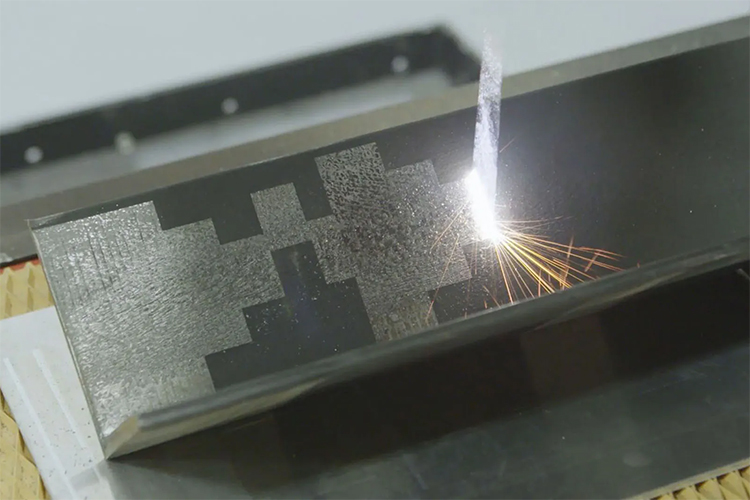

Laser Rust Removal: Metal materials exposed to humid environments can rust, reducing their performance and lifespan. Traditional methods like sandblasting and chemical cleaning are effective but harmful to the environment and health. Laser rust removal, being eco-friendly, efficient, and precise, has become a preferred method in industrial applications, effectively removing rust while preserving the base material.

Laser Paint Removal: Large equipment like ships, aircraft, and bridges require regular repainting, which first involves removing old, damaged paint. This process, known as paint removal, must ensure thorough removal without damaging the substrate. Compared to traditional techniques, laser cleaning is greener, safer, and more efficient, making it ideal for complex structures like aircraft, ships, and rail components.

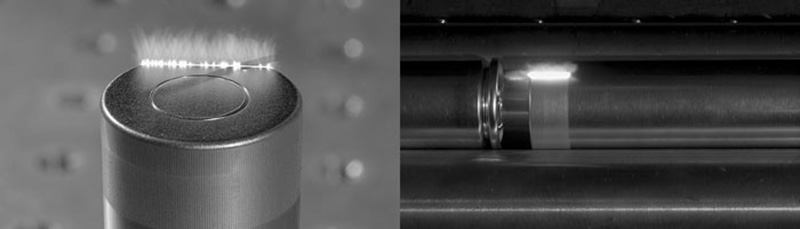

Laser Cleaning of Electronic Components: Tiny contaminants on electronic components can reduce efficiency or damage circuit boards. As semiconductors and microelectronics become smaller, the need for precise cleaning increases, making traditional methods insufficient. Laser cleaning is highly accurate, easily automated, and adjustable, effectively removing dust, grease, and oxides from surfaces, enhancing the reliability and lifespan of components. It is widely used in cleaning printed circuit boards, silicon wafers, integrated circuits, flexible circuits, and optoelectronic devices.

Precision Instrument Cleaning: Traditional chemical methods are commonly used to remove oils and greases from precision instrument parts, but residues often remain. Laser cleaning can completely remove oils without damaging the surface. It works by creating shockwaves from the rapid vaporization of surface oxides, removing contaminants without mechanical interaction.

Glass and Ceramics: Laser cleaning is ideal for removing coatings and contaminants from glass and ceramic surfaces. Its non-abrasive, non-contact nature ensures that these fragile materials are not damaged during the cleaning process.

Plastics and Rubber: In modern manufacturing, laser cleaning is also used to remove oil, coatings, and oxides from molds and precision rubber seals. This process prepares surfaces for subsequent production steps while avoiding damage with traditional cleaning methods.

Laser Cleaning of Artifacts: Artifacts often have soil, corrosion, dust, organic stains, and rust on their surfaces. Given their value and irreplaceability, cleaning requires great care. Traditional methods like chemical or mechanical cleaning can damage the artifacts. Laser cleaning can safely remove dirt from sculptures and other objects (such as limestone, marble, and bones) without harming the artifact itself. The technology’s selectivity, eco-friendliness, non-contact approach, and high control make it a leading solution for cleaning, restoring, and preserving cultural relics.

What Materials are Not Suitable for Laser Cleaning?

- Highly Reflective Materials

Laser cleaning relies on directing a high-energy laser beam onto the material’s surface to remove contaminants through the photothermal effect. However, highly reflective materials, such as mirror-finished metals or certain types of plastics, can reflect most of the laser energy. This reduces the effectiveness of the cleaning process, as the laser energy is not efficiently absorbed by the contaminants.

- Heat-Sensitive Materials

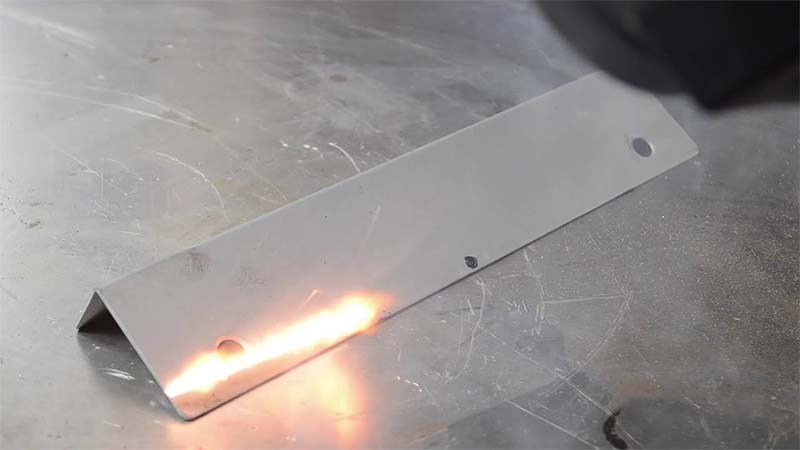

The laser cleaning process involves exposing the surface to high temperatures. For heat-sensitive materials, like some types of rubber or paper, this can cause damage, deformation, or even ignition, making them unsuitable for laser cleaning.

- Heat deformable materials

Certain materials, such as thin metal sheets or lightweight plastic products, are prone to warping or bending under laser heat. The heat stress during laser cleaning may deform these materials.

- Items with Special Coatings

Many items have special coatings, such as anti-reflective coatings on optical lenses or conductive coatings on electronic products. Laser cleaning can damage these coatings, reducing performance or causing the item to lose its intended function.

Why Choose DPLaser for Custom Laser Cleaning Machines?

- Tailored Solutions

We understand that each industry has unique requirements. That’s why we offer custom laser cleaning system designed to meet your specific needs. Whether you require portable handheld laser cleaner or integrated automated systems, we can provide the right laser cleaning systems for surface treatment of metals, non-metals, and sensitive or fragile materials.

- Comprehensive Customer Support

Our team offers professional technical support and after-sales service. From installation and training to troubleshooting, our experts ensure that your machine operates smoothly with minimal downtime. We are committed to delivering the best customer experience and supporting your business needs.

- Affordable Price

The price of laser cleaning machine depends on factors such as brand, model, and power. Current market prices range from several thousand to tens of thousands of dollars. The specific cost will depend on your needs, budget, and machine configuration. Share your material type and requirements with us, and we will help you select and customize the perfect laser cleaning machine for your application.

In summary, laser provides an efficient solution for cleaning sensitive materials, providing precision and control to minimize substrate damage. Understanding the specific needs of the material and choosing the right laser cleaning machine for sensitive material is essential for achieving the best results. Using Dapeng Laser’s cleaning equipment can non-destructively process the surfaces of metals, non-metals, and even delicate materials. Choose us to improve your cleaning needs and ensure optimal performance for a variety of industrial applications.