Fully Enclosed UV Precision Laser Cutting Machine

The ultra-precision UV laser cutting machine is a highly advanced and specialized piece of equipment designed for high-precision cutting applications. It utilizes ultraviolet (355nm) laser technology, which provides an extremely focused beam capable of making precise and intricate cuts on a wide variety of materials with minimal thermal impact. UV laser can apply high-contrast markings on sensitive products.

This machine is fully enclosed, ensuring a safe operating environment by containing potentially harmful laser emissions and preventing dust or debris from interfering with the cutting process. The enclosure also helps maintain a stable internal environment that is crucial for maintaining consistent cutting precision.

Equipped with advanced control software and high-accuracy positioning systems, it can handle complex designs with micron-level precision. It is commonly used in industries such as microelectronics, semiconductor manufacturing, medical device production, and other fields where fine detail and clean, accurate cuts are essential.

- This is an industrial UV laser marking machine with patented technology of self-adjusting Z-axis and all-around safety cover. Features include a large, easy-to-open door for comfortable and efficient loading and unloading.

- UV laser markers for highly sensitive materials enable precise marking of extremely fine lines and high contrast without compromising material performance and integrity.

- The workstation is equipped with a fully-enclosed shield to enhance overall safety and an advanced smoke purification system to reduce smoke and dust emissions during laser processing, protecting the environment and operator health.

- The UV laser marking system complies with EU and ISO standard certification and has been certified to maintain stability and reliability even under high-speed operation.

Features:

- The combination of high-precision, low-drift mirrors and servo system platform provides outstanding micrometer-level cutting accuracy, with cutting precision up to ±25um.

- Years of practical experience in process debugging ensure excellent beam quality, with a minimum line width of 25um, minimal heat-affected zone, and low thermal distortion.

- The integrated cabinet with a 60*60mm square steel structure and optical marble platform supports the laser and optical path system, ensuring equipment stability during operation.

- The integration of stress-free cutting mode with fully automatic CCD positioning system delivers perfect cutting results, with smooth edges, no burrs, and no cutting residue.

- Multi-board splicing cutting, automatic positioning, automatic calibration, and automatic expansion/contraction compensation achieve splicing accuracy up to 10um.

- Supports direct import of DXF files for cutting.

Applications:

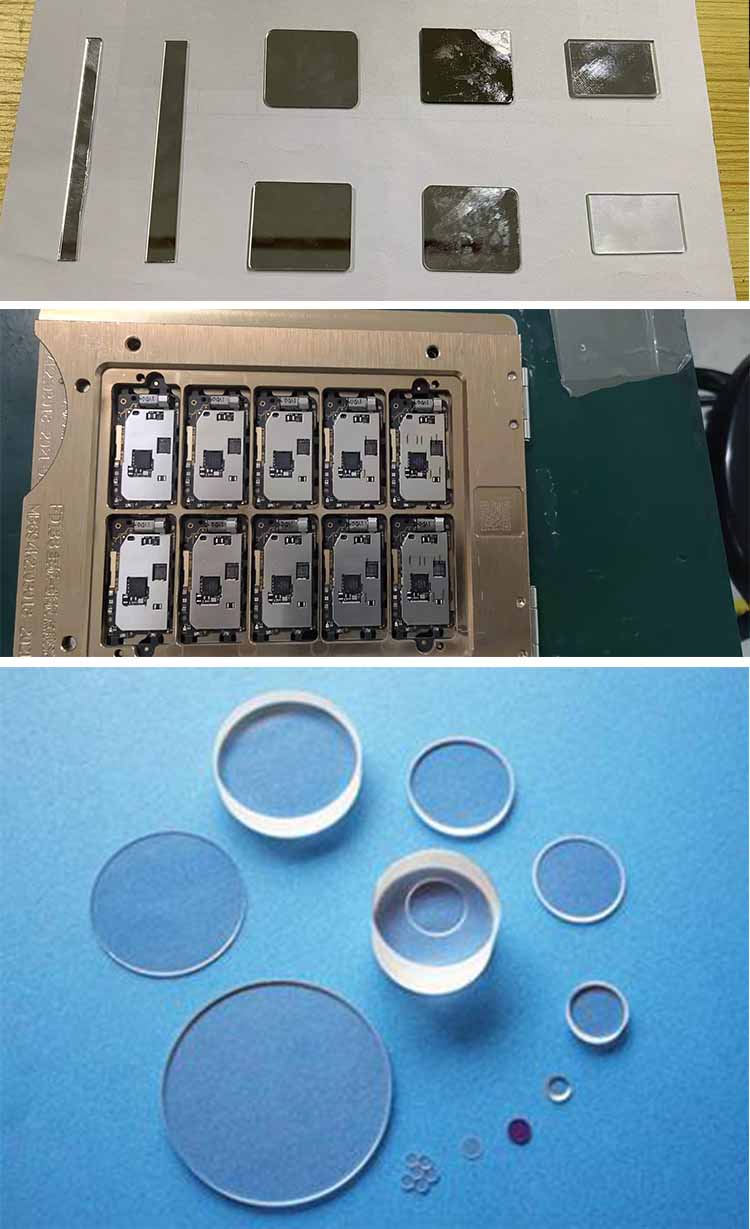

FPC/PCB, flex-rigid, FR4, cover films, ceramics, silicon, sapphire, silicon wafer micro-holes, blind hole processing, LCD glass QR code marking, drilling on glassware surfaces, coating marking on metal surfaces, plastic buttons, and marking on electronic components etc.

Reviews

There are no reviews yet.