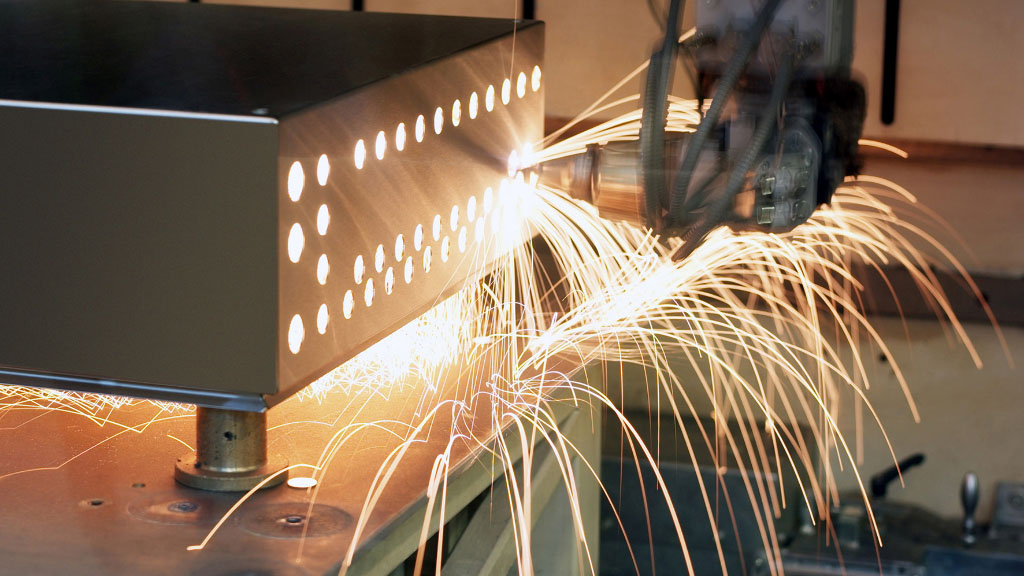

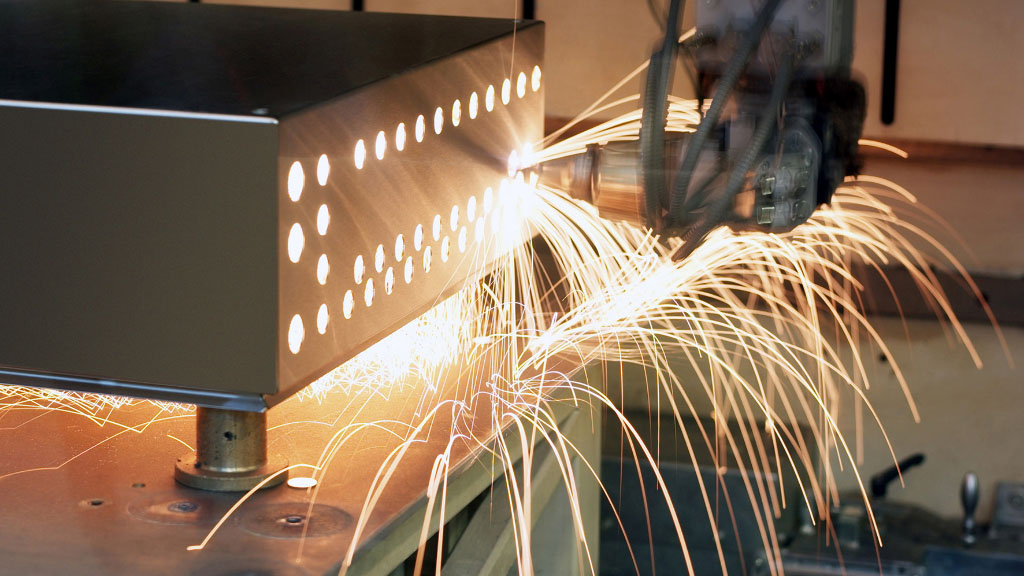

3D Metal Laser Engraving & Cutting

What is 3D laser cutting?

3D laser cutting machine is an industrial device capable of precisely cutting within three-dimensional space using a laser beam. Unlike traditional flat laser cutting, 3D laser cutting systems possess the ability for multi-axis movement, enabling precise engraving, drilling, and cutting of complex three-dimensional workpieces, sheets, and pipes in various directions.

Its distinctive advantages lie in high precision and complexity, meeting the cutting and engraving needs of intricate structures; efficiency, rapidly completing the cutting of large quantities of workpieces; non-contact cutting, thereby reducing the likelihood of mechanical damage; applicability to various materials, demonstrating strong material adaptability; and high automation, achieving process automation through multi-axis movement systems, ultimately enhancing overall production efficiency.

What Can 3D Laser Cutter Do?

The fiber laser cutting machine is primarily designed for engraving and cutting on flat surfaces. With the rotary axis, it can also be employed for marking on some three-dimensional objects, such as cups, trophies, and bracelets. However, Laser engraving of curved surfaces is still subject to many limitations. Therefore, 3D fiber laser engraving machines have gained widespread popularity for curved embossing engraving, cylinder engraving, three-dimensional cutting, and etching.

- Home and Building

3D metal laser cutting technology finds application in crafting metal decorative materials, such as staircase handrails, railings, and artistic engravings. - In the Energy Sector

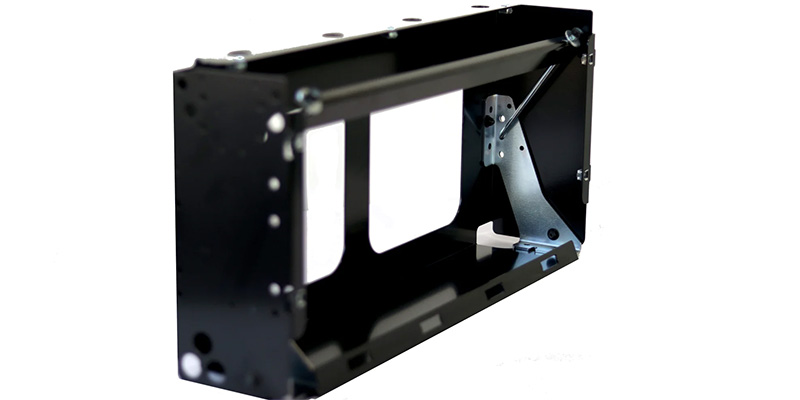

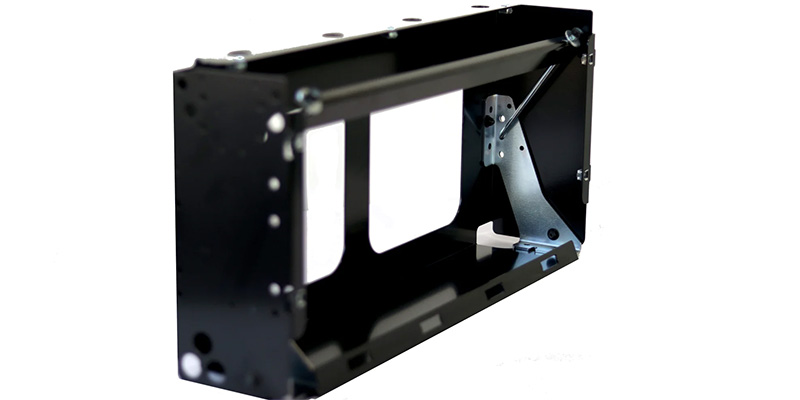

Utilizing 3D metal laser cutting techniques contributes to the fabrication of components for energy equipment, including items like brackets for solar panels and parts for wind turbine generators. - Electrical Industry

In the realm of the electrical industry, 3D laser cutting systems for metal prove valuable in producing outer shells and structural elements for electrical devices, ensuring products meet high precision and dimensional standards. - Light Industry

The versatile application of 3D metal laser cutting machines spans various light industries, encompassing the manufacture of furniture, metal artworks, and decorative items. - Artwork

The 3D cutting and engraving technology in art allows artists to create unique and vibrant artworks by realizing complex three-dimensional structures, personalized customization, utilizing diverse materials, and achieving intricate patterns. Simultaneously, it offers a solution for small-batch production.

- Mechanical Manufacturing

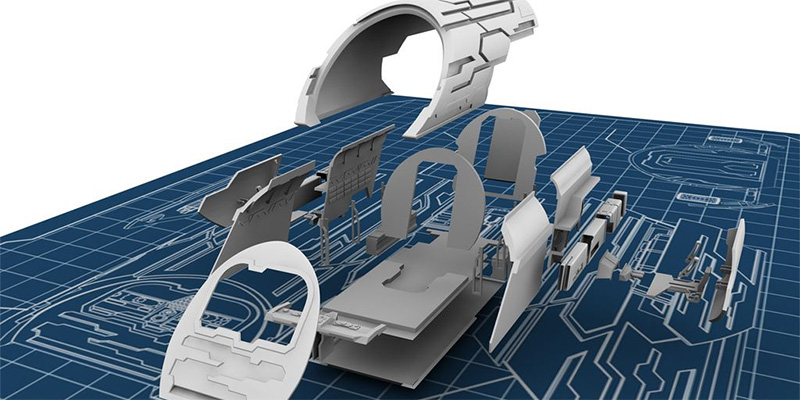

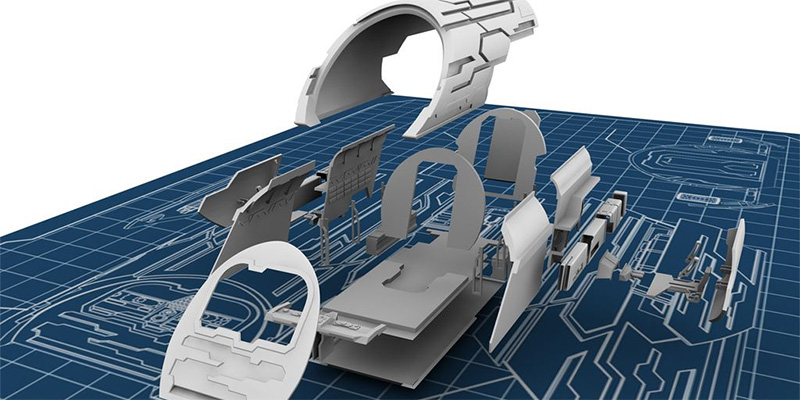

Within mechanical manufacturing, the implementation of 3D laser cutting for metal extends to the production of mechanical components like gears, bearings, and connecting elements. - Aerospace Industry

The aerospace sector leverages the capabilities of 3D laser cutting in metal for crafting aircraft components such as wings, fuselage sections, and engine parts. The technology’s high precision and intricate capabilities make it an indispensable tool for aerospace manufacturing. - Automotive Manufacturing

In the automotive manufacturing arena, the widespread use of 3D fiber laser cutting in metal is evident in the production of diverse automotive components, ranging from body structures to chassis components and interior elements. - Shipbuilding

3D laser cutting metal is integral to shipbuilding processes, contributing to the precision cutting and shaping of structural components for ship hulls. This application enhances manufacturing efficiency while ensuring the accuracy and uniformity of the ship’s structure.

3D Laser Engraving vs 2D Laser Engraving

2D Metal Sheet Laser Engraving

3D Metal Laser Engraving

Benefits of 3D Laser Cutting & Engraving in Industry

3D Shape Adaptability – 3D laser cutting & engraving excels in handling intricate contours and three-dimensional shapes.

Increased Design Freedom – The technology allows greater design flexibility, accommodating components with varying heights and shapes, providing designers more creative freedom compared to traditional flat cutting.

Precision on Complex Surfaces – Laser engraving maintains high precision on irregular or contoured metal surfaces, overcoming the limitations of flat cutting in accuracy across diverse shapes.

Efficient 3D Prototyping – 3D laser cutting enables rapid prototyping of three-dimensional components, facilitating quick design iterations.

Seamless CAD Integration – three-dimensional laser cutting aligns seamlessly with 3D CAD models.

Precision in Layered Structures – In applications with layered structures, such as additive manufacturing, 3D metal laser cutting provides precise cutting across multiple layers.

GET YOUR SOLUTIONS

Get a Free Quote

Share your needs, and our professional engineers will offer tailored machines and free quotes for your business.

Contact Us

Welcome to DPLaser to experience and learn to use laser equipment.

Live Chat

We are always here!