Laser Cutting Machine for Wood & Cardboard

What can you make with a wood laser cutter?

Laser cutting can produce intricate shapes and contours as per design requirements, while laser engraving can create fine patterns, text, or images on the surface of wood.

Laser cutting technology is widely used for processing various wooden objects, including personalized toys, signage, puzzles, crafts, decorations, greeting cards, cardboard, and even architectural models and wooden cabinet.

CNC laser cutting machines can efficiently complete multiple repetitive cutting projects in a shorter time, minimizing material wastage and rough edges, offering flexibility, efficiency, and precision in wood product manufacturing.

What Projects Can Handle with a Wood Laser Cutters?

Wooden Crafts Manufacturing

Laser cutting technology can be used to create wooden crafts such as wood carvings, wooden figurines, wooden puzzles, and carved art pieces. It allows artisans to create intricate and complex designs to meet personalized needs.

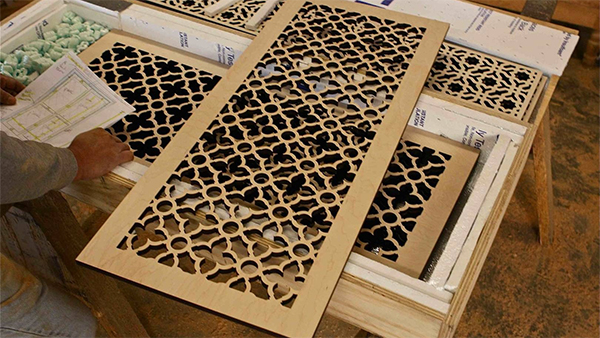

Interior Decor

Laser cutting systems can be used to produce interior decorations, including decorative wall panels, lighting fixtures, cabinets, and other furniture.

Wooden Toy Manufacturing

Laser cutting wood is used in the production of wooden toys, including wooden puzzles, building blocks, 3D model, and more. These toys often require batch production with precise cutting and engraving.

Textiles & Clothing

The laser cutting machine has the capability to precisely cut silk fabric, enabling the creation of intricate designs and patterns. It finds extensive applications in custom apparel production, embroidery, decorative item manufacturing, label and logo creation, as well as the production of home textiles.

Customized Cardboard Boxes

Laser cutting machines can cut cardboard in bulk to match the size and shape requirements of products. This provides a highly flexible and precise method for producing cardboard boxes.

Wooden Gifts and Souvenirs

Laser engraver is applied in the production of wooden gifts, such as gifts, greeting cards, wooden sculptures, souvenirs, and trophies. It allows for personalization by engraving text and patterns on wooden surfaces.

Architectural Models and Inlays

Laser cutting for creating models, including house models, architectural models, and landscape models. Additionally, it can be used to craft intricate wooden inlays such as parquet floors, door and window decorations, and wooden murals.

How to Choose the Best Wood Laser Cutter for Small Business?

1. Establish a Budget

Define a budget for purchasing a wood laser cutter. Laser cutter prices vary significantly, so having a clear budget will help narrow down your choices.

2. Determine Your Requirements

Consider the specific needs of your small business. What type of materials will you be cutting? What are the maximum dimensions of the materials you’ll be working with? What accurate is the cutting required? Clarifying your requirements will guide your selection.

3. Laser Power

Laser power determines the machine’s ability to cut through different materials and thicknesses. For wood applications in small businesses, a CO2 laser cutter with a power range of 40 to 100 watts is typically suitable.

4. Work Area Size

The work area size, also known as the cutting area, should be capable of accommodating the largest pieces you intend to process. When choosing the work area size, consider both the physical dimensions and thickness of the materials.

5. Laser Type

There are two primary types of laser tubes: CO2 and fiber. CO2 lasers are versatile and particularly well-suited for wood, while fiber lasers are better for metal applications. Choose a CO2 laser cutter for wood.

6. Maintenance and Support

Assess the ease of maintenance and repair for the machine. You’ll want the ability to perform routine maintenance on components or obtain replacements at a reasonable cost.

Please tell us more information to get the equipment that is more suitable for your business.

For small businesses, the primary challenge is the initial cost of the machine. Additionally, acquiring some specialized knowledge may be necessary to effectively set up and operate the equipment. As a leading laser equipment manufacturer in China, we are committed to assisting our customers’ business growth with competitive pricing. Our comprehensive training and support systems ensure a hassle-free experience after your machine purchase.

Get a Free Laser Cutting Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.