Metal parts and finished equipment often develop oxide layers during forging, hot rolling, or welding processes. For example, steel used in railway tracks can form dense oxides after heat treatment, and weld seams are particularly prone to oxidation. These oxide layers not only affect subsequent processing but also reduce the surface quality and performance of the product. Compared with traditional cleaning methods, laser cleaning oxide on metals can restore the metal’s original luster and performance effectively.

How Does a Laser Oxide Removal Machine Work?

The laser cleaning for removing metal surface oxides is based on the physical interaction between high-energy laser beams and metal oxides. The core mechanism relies on the stripping of the oxide layer through photothermal, photochemical, or photomechanical effects, while simultaneously protecting the underlying substrate.

Photothermal Effect

When a laser beam is focused, it generates high temperatures, causing the metal oxide to rapidly absorb energy and heat up. Once the temperature exceeds the melting point or decomposition threshold of the oxide layer, the oxides melt, vaporize, or decompose, eventually detaching from the substrate surface. This process leverages the differential absorption of laser energy by various materials, ensuring efficient removal of the oxide layer without damaging the substrate.

Photochemical Effect

Lasers of specific wavelengths can break chemical bonds within metal oxide molecules, decomposing them into smaller molecules or volatile substances. This process does not require high temperatures; the photon energy directly disrupts the chemical structure of the oxide layer, enabling low-temperature, non-thermal-damage cleaning.

Photomechanical Effect

Laser pulses can generate plasma shockwaves or stress waves on the surface of the oxide layer, mechanically vibrating and stripping the oxide from the substrate. This mechanism is particularly effective for hard or strongly adherent oxide layers, relying on physical impact rather than heat to achieve efficient removal.

Why Choose a Laser Cleaning Machine for Oxide Removal?

High Efficiency and Speed

Laser cleaning can process large surface areas in a short time, far surpassing traditional methods such as sandblasting or chemical cleaning. It is especially suitable for fast rust and oxide removal on large metal components.

Non-Contact Cleaning

Laser cleaning requires no physical contact or chemical agents. The beam operates remotely, eliminating risks of mechanical wear and chemical corrosion. This makes it ideal for delicate, high-value, or complex metal parts, such as medical instruments or cultural relic restoration.

Eco-Friendly

No chemical reagents are needed during laser cleaning, and no wastewater or harmful gases are produced. Removed contaminants are mostly small, collectable solid particles, significantly reducing environmental impact.

Precise and Non-Damaging

Laser beams can be precisely controlled through focusing and scanning parameters, targeting only oxide layers on complex structures or delicate components without harming the substrate. This is critical for applications such as precision electronics or aerospace alloys, where the microstructure and performance of the material must be preserved.

Wide Applicability

By adjusting laser parameters—wavelength, power, and pulse width—cleaning can be optimized for different metals (e.g., steel, aluminum, copper) and their oxide characteristics. For example, low energy density can be used to remove aluminum oxide without overheating the substrate, while higher energy density can achieve deep oxide removal on stainless steel.

Easy Automation

Laser cleaning systems can be integrated with robotic arms or CNC machines for stable, high-speed, and repeatable automated cleaning. This significantly improves production efficiency and reduces labor costs.

Effective of Laser Remove Oxides from Metal

The effectiveness of laser cleaning is closely related to laser power. Choosing the appropriate power and parameters depends on the material type, oxide layer thickness, and desired cleaning outcome.

1. Material Type

Metals: For metal surfaces such as steel and aluminum, medium to high-power lasers (1000W~3000W) are usually required to ensure effective oxide removal.

Non-Metals: For plastics or composite materials, lower-power pulsed laser cleaners (100W~500W) should be used to avoid damaging the substrate.

2. Oxide Layer Thickness

Thin Oxide Layers: Light oxidation or surface contamination can be removed with low-power lasers (100W~500W) for fast cleaning.

Thick Oxide Layers: Heavily oxidized surfaces or long-term oxide buildup may require higher-power lasers (1000W~3000W) to ensure complete removal.

3. Desired Cleaning Effect

Precision Cleaning: For applications that require preserving surface smoothness or avoiding thermal effects on the substrate, pulsed laser cleaning is recommended. This enables high-precision surface cleaning.

Rapid Cleaning: For faster oxide removal, continuous-wave laser rust removers can be used. However, compared to pulsed lasers, continuous lasers may introduce some thermal impact on the substrate.

4. Cleaning Speed and Efficiency

Higher-power lasers generally provide faster cleaning speeds, but this may come at the expense of precision.

How to Choose a Laser Cleaning Machine for Metal Oxides

Small or Precision Cleaning

For small workpieces, precision components, or applications requiring high surface quality, a 100W~500W pulsed laser cleaning machine is recommended. It is ideal for delicate or detailed cleaning tasks.

Large or Heavy Oxide Cleaning

For thick oxide layers or large-area contamination, a 1000W~3000W fiber laser cleaning machine is recommended. It provides high efficiency and is suitable for large-volume industrial production

Industrial Applications of Laser Cleaning for Oxides

Metal Rust Removal

Laser cleaners can efficiently remove rust layers from metal surfaces. Higher laser power results in stronger rust removal capability and higher cleaning efficiency. Pulsed lasers with QBH output are ideal for system integration, offering strong cleaning ability and high efficiency.

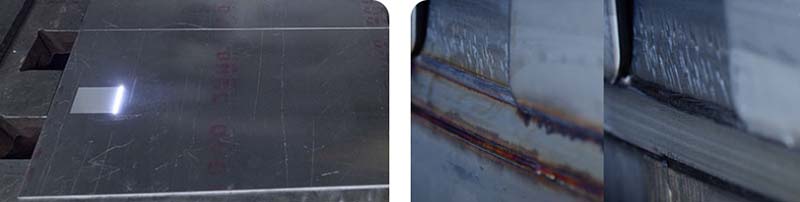

Weld Oxide Cleaning

Oxides and impurities formed during high-temperature welding can affect weld quality and appearance. Laser cleaning system precisely removes oxides from weld seams and surrounding areas, ensuring a smooth, aesthetically pleasing, and reliable post-weld surface.

Precision Component Cleaning

Laser cleaning produces minimal thermal impact, effectively removing surface contaminants with little material deformation. It is suitable for precision components and sensitive materials requiring careful surface treatment.

Mold Cleaning

Molds can accumulate plastic residue, metal debris, or dust during use, affecting product surface quality and accelerating wear. Laser cleaning efficiently removes residues without damaging the substrate, extending mold service life.

Laser cleaning provides a highly efficient, non-damaging, and precisely controllable surface treatment solution, making it ideal for metal processing, welding, precision manufacturing, and mold maintenance.

Laser Remove Oxide Layer from Aluminium

During processing and use, aluminum surfaces easily form a dense aluminum oxide film, which negatively affects appearance, gloss, electrical and thermal conductivity, and mechanical properties. It also interferes with subsequent coating and welding processes. The complex geometry of curved surfaces makes traditional cleaning methods difficult to apply comprehensively. In addition, aluminum alloys are relatively soft and prone to mechanical damage, while conventional chemical cleaning or grinding is inefficient and may harm the surface.

Laser cleaning offers a non-contact solution. A high-energy laser beam acts on the oxide layer, causing it to peel off instantly without introducing mechanical stress or damage. This protects the precision and integrity of complex surfaces. Laser parameters such as position, energy, and scanning path can be precisely controlled, enabling accurate cleaning even in deep grooves, curved areas, or edges—while preserving the original shape and properties of the substrate.

Beyond oxide removal, laser cleaning can also eliminate oil, dust, and organic coatings in a single process, without the need to switch cleaning agents or methods. This simplifies workflows and ensures consistent results. Intelligent control systems can automatically adjust parameters based on aluminum material, thickness, and oxidation level, enabling large-area plates or complex components to be cleaned efficiently and thoroughly, with no blind spots.

Laser cleaning of aluminum is widely applied in electronics manufacturing, automotive parts processing, and surface treatment of various aluminum products.

Application of Laser Remove Oxidation from Aluminum

Welding Preparation

Removing the oxide layer before welding aluminum is essential to ensure strong, defect-free welds. Laser cleaning is highly effective in this process, as it precisely cleans the welding area, improving weld quality and reducing defects.

Surface Restoration

Laser cleaning can restore aluminum components by removing oxide layers, corrosion, and old coatings. This process renews the surface without altering the dimensions or mechanical properties of the part.

Pre-Coating Treatment

For applications requiring coatings or adhesive bonding, laser cleaning ensures an oxide- and contaminant-free aluminum surface. This improves adhesion strength and extends surface finish durability. With its precision, laser cleaning provides uniform treatment across the entire surface, which is critical for achieving high-quality coatings.

The Best Laser Cleaning Oxide on Metals

This fiber laser cleaning system provides a non-contact, eco-friendly, and highly efficient solution for removing rust, oxides, coatings, and surface contaminants from metals. With integrated design, intelligent control, and versatile cleaning modes, it delivers precision, stability, and adaptability across a wide range of industrial applications.

Integrated Design with Flexible Laser Options

Available with either a MOPA pulsed fiber laser or a flat-top pulsed fiber laser, ensuring stable performance and adaptability to diverse cleaning requirements.

Advanced Control System

Pre-installed with Dapeng’s self-developed multifunctional laser cleaning control system, allowing seamless integration with various industrial automation lines for efficient, intelligent operation.

Built-in Fume Purification

Equipped with a high-efficiency smoke and dust purification system to ensure low-emission operation in compliance with environmental standards.

Optional Dual-Temperature Water Cooling

Dual-temperature, dual-control water cooling system available to guarantee long-term stable operation of both the laser and cleaning head, extending equipment lifespan.

Versatile Cleaning Modes

Offers multiple beam oscillation patterns—including square, circular, and six others—with adjustable swing widths from 0 to 120 mm, delivering comprehensive cleaning results across different applications.

Wide Application Range

Ideal for precision molds, metal parts, shipbuilding, construction, automotive manufacturing, sheet metal, painting, and other metal surface cleaning or laser pretreatment processes.

Laser cleaning offers a precise, non-contact, and highly efficient solution for oxide removal. Unlike traditional methods, it can thoroughly clean even complex surfaces without damaging the substrate. By eliminating oxide layers, it not only reduces processing costs and labor but also improves welding strength, coating adhesion, and overall product quality, making it an ideal choice for metal processing.

When it comes to achieving superior processing results, choosing the best laser cleaning oxide on metals is essential. This technology ensures precise, non-contact removal of oxide layers without damaging the underlying surface, while improving efficiency and reducing environmental impact. By investing in the DaPeng laser cleaning solution, you can maintain metal quality, enhance production workflows, and achieve long-term cost savings.