The laser engraving power settings affect the depth, clarity, and speed of the engraving process, making it essential to understand the appropriate settings for each type of material. In this article, we’ll delve into which laser power for metal engraving, explore optimal settings for different metals and plastics, and guide you on selecting the best laser power for your needs. We will also introduce our fiber laser marking machines, designed to provide precision and efficiency for all your engraving applications.

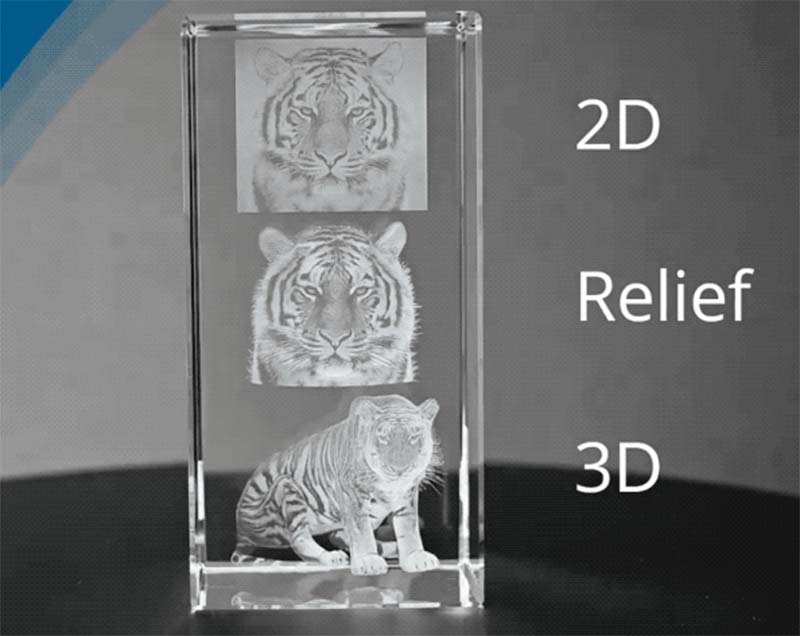

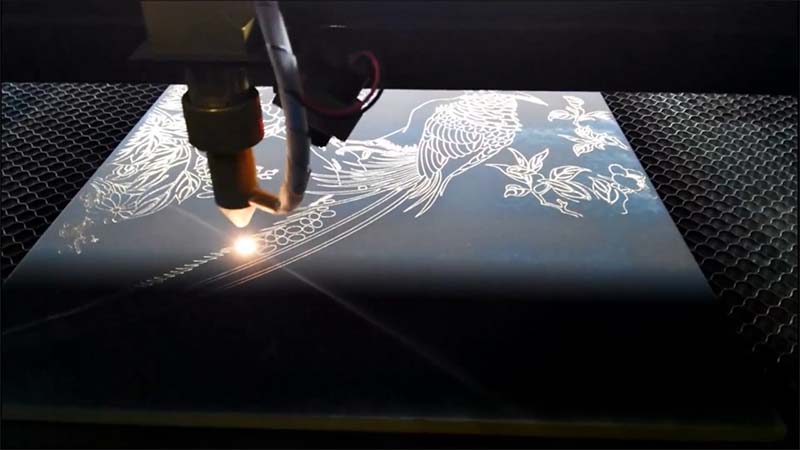

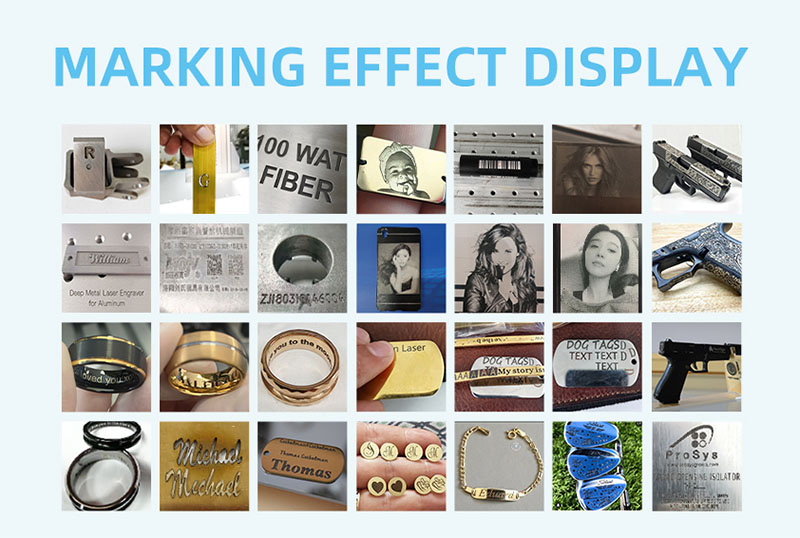

Laser engraving is a technology that inputs information from a computer file or image scanner into a laser engraving system, using a high-energy laser beam to engrave and print on the surface of the target material. In the metal processing industry, laser engraving is widely used. Laser engraving on metal mainly includes engraving logos and markings, making advertisements, nameplates, molds, handicrafts, leather products, circuit boards, and personalized products, among others.

Laser engraving power refers to the amount of energy radiated by the laser. The greater the laser power, the deeper the engraving depth and the faster the speed. However, if the power is too high, it may burn the material.

For example, a 20W laser marking machine marking on plastic samples actually only requires 5W of power; if the power is too high, the marked text and patterns may turn yellow. Therefore, when using laser engraving, it is necessary to adjust the appropriate power parameters according to the material being processed.

Which Laser Power Do You Need for Engraving?

In laser engraving system settings, the power is adjusted as a percentage, ranging from 0% to 100% output power. The default setting is usually 50% output power. The higher the output power is set, the greater the laser energy output, making it easier to achieve deeper or faster engraving.

Frequency of the Laser Marking Machine

The number of pulses per unit of time is called the frequency of the laser marking machine. When adjusting the frequency, a higher marking frequency results in denser laser dots, while a lower marking frequency results in more spaced-out laser dots.

Laser Type and Power for Laser Engraving

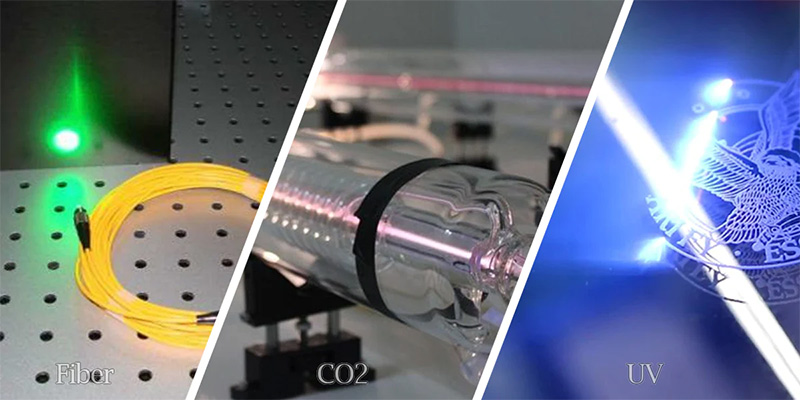

The power of laser engraving machines vary widely, ranging from 3W~200W. Based on the wavelength of the laser, the power is divided into three types: CO2 lasers, fiber lasers, and UV lasers.

CO2 Lasers

CO2 lasers have a wavelength of 10.6 μm and are primarily used for cutting, engraving, and etching non-metallic materials. Their power ranges from 20W to 150W. Generally, the thicker or harder the material to be engraved, the higher the power required to complete the task.

Fiber lasers have a wavelength of 1.06 μm and are suitable for cutting and engraving metal materials. Low-power fiber lasers (20W~200W) can be used for metal marking and deep engraving. High-power fiber lasers, such as those ranging from 1500W ~6000W, can be used for cutting large-sized metal sheets.

Metals: Fiber lasers are particularly adept at processing metals like stainless steel, aluminum, brass, and copper, which are ideal for creating high-contrast permanent marks.

Plastics: Not all plastics are suitable for laser engraving, as some may melt or burn. Fiber lasers are typically only effective on laser-friendly plastics that respond well to laser energy, such as ABS, PE, and PVC.

UV Lasers

UV laser marking machines typically use ultraviolet lasers with a shorter wavelength, around 355 nm, and usually have a power output of 3W~10W. This short wavelength and low power allow for more precise processing with minimal thermal impact on the material’s surface. Therefore, UV lasers are especially suitable for precision applications such as marking and micro-machining of glass, ceramics, plastic cosmetics, pharmaceuticals, food, PCBs, QR codes, metal surface coatings, and plastic buttons.

Laser Engraving Power Settings

When using a laser marking machine to engraving different materials, setting the correct power parameters is crucial for ensuring marking quality. Below is a basic laser engraving power and speed for some common materials.

Higher engraving speeds are suitable for shallow engravings and simple patterns, while lower speeds are better for deep engravings or intricate and complex patterns. The specific choice of engraving speed should consider the engraving precision, material characteristics, as well as the type and power of the laser.

These parameters can serve as an initial reference, but adjustments should be made based on specific conditions in practical applications.

| Materials | Lasers | Power range (W) | Speed (mm/s) | Tips |

| Wood | CO2 | 15-100 | 300-500 | Cannot be used at too high a power level or it will scorch |

| Leather | CO2 | 15-50 | 200-300 | Similar to wood, scorching must be avoided |

| Plastic | CO2/Fiber | 15-50 | 300-500 | Higher power should not be used as it can cause distortion of the plastic. |

| Acrylic | CO2/UV | 25-50 | 100-200 | Higher power can be used, but whitening must be avoided |

| Glass | UV | 3~10 | 100-200 | Do not use high power or it will crack |

| Metal | Fiber | 30-500 | 40-60 |

What Laser Power to Engrave Metal

Iron: requires at least 30W of laser power for engraving.

Aluminum: requires at least 20W of laser power for lettering.

Copper: Usually requires more than 30W of laser power for clear lettering.

Laser Power to Engrave Stainless Steel

Different types of metals have varying thermal conductivity and reflectivity, requiring laser engraving machines of different power levels for processing. For example, stainless steel has good thermal conductivity and reflectivity, necessitating a high-power laser engraving machine.

Laser Power: When marking stainless steel, a certain laser power is required. It is generally recommended to choose a laser power of 30W to 50W, with an initial power setting of 50%.

Distance between Laser Head and Stainless Steel: It is generally recommended to maintain a distance of 3-5mm.

Focal Length: The position of the laser focus affects the marking effect. A focal length of around 100mm is generally recommended.

Pulse Frequency: For stainless steel materials, the pulse frequency should be set between 20-80 kHz. A frequency that is too low will result in slow engraving speed, while a frequency that is too high will result in insufficient engraving depth.

Marking Speed: The speed should be set to 300mm/s. The marking speed should be chosen based on the thickness of the stainless steel; too slow a speed will result in poor marking effects, while too fast a speed may affect repeatability and quality.

Line Spacing: The line spacing is typically set to around 0.05mm. Different filling densities and line types can be tested to achieve the desired engraving effect.

Repeatability: High repeatability is required for marking stainless steel, typically within 0.01mm.

The marking pattern should be adjusted and checked before marking to ensure that the pattern is clear and accurate. Multiple proofs and parameter adjustments can be made first to find the most suitable stainless steel laser marking parameters.

Laser Power Settings to Mark Plastic

If you want to use a 30W fiber laser marking machine for ABS plastic. You should set the initial power setting to 30% and the speed setting to 500mm/s.

How to Adjust Laser Engraving Power and Speed?

- Initial Setup and Testing: Start by setting the power and speed to around 50%. Choose a test sample for an engraving experiment to check the engraving effect.

- Adjust the Power: If the pattern is too light or the engraving is insufficient, increase the power. Conversely, if the material is overcut or the engraving is too deep, decrease the power. Generally, for materials with higher density, you need to increase the power, while for more brittle or softer materials, the power can be reduced appropriately.

- Adjust the Speed: If the pattern is not clear enough or there are burrs, try reducing the speed. Similarly, if the engraving is too deep, too wide, or has too many rough edges, increase the speed.

- Test on Scrap Material: Before engraving the final workpiece, test the laser power on similar scrap material to determine the appropriate settings and ensure satisfactory results.

How to Choose the Laser Engraver Power?

The power level is not only one of the main factors affecting the price of a laser marking machine, but it also directly determines the marking quality and efficiency. A higher-power laser marking machine means a higher price and demands more advanced hardware configuration for the equipment.

Power Specifications and Applications

20W Laser Marking Machine: This power level is typically sufficient for most everyday marking needs and is suitable for various common materials, such as stainless steel and aluminum alloys. For most standard marking tasks, 20W is enough

30W Laser Marking Machine: A 30W lasers greater flexibility, allowing faster processing speeds while maintaining the same marking effect by adjusting the power. It can also handle tasks that require more power.

50W Laser Marking Machine: This high power laser engraving machine is suitable for applications that require intense marking, such as marking heavy-duty industrial parts. In addition, the 50W laser has a wider adaptability range and can be adjusted to 20W~30W to meet different marking needs.

Power Adjustment Considerations

It is important to note that high-power equipment can be adjusted to lower power settings, but low-power equipment cannot provide high-power functions. This means that if there is a possibility of needing to handle more complex or thicker materials in the future, it might be wise to choose equipment with a higher maximum power.

Practical Operation Tips

Before actual operation, be sure to test gradually using samples to determine the optimal marking parameters. Even for the same type of material, the required marking parameters may vary under different environmental conditions (such as temperature and humidity). Therefore, every time you change materials or adjust the working environment, recalibrate the settings of the laser marking machine to ensure the desired marking effect.

Laser Engravers and Cutters

The DPLaser FC Series laser marking machines, equipped with 20-30W fiber lasers, meet most metal marking and engraving needs. The optional MOPA fiber laser offers adjustable frequency (1-3000kHz) and pulse width (2-500 nanoseconds), enabling vivid color marking on metal surfaces like stainless steel and aluminum, as well as precise cutting, drilling, and complex pattern design on plastic buttons, delivering high-quality and accurate visual effects.

Machine Advantages:

Fiber Laser Technology: Equipped with a powerful fiber laser source that ensures clear and precise engraving on metal surfaces.

High-Speed Engraving: Boost your productivity with lightning-fast scanning and engraving without compromising on quality.

Dynamic Focusing System: Dynamically adjusts the focal length to maintain consistent engraving depth across varying material thicknesses.

Versatility and Flexibility:

Compatible with Various Metals: In addition to aluminum, it can engrave stainless steel, brass, copper, and more, making it ideal for diverse projects.

Adjustable Engraving Depth: Easily customize engraving depth and intensity, giving you complete control over the outcome of your projects.

Seamless Software Integration: Seamlessly integrates with popular engraving software for intuitive control and a streamlined workflow.

When choosing a metal laser engraving machine, consider the diversity of technology, ensure high quality and precision, and factor in long-term cost-effectiveness, including maintenance costs and return on investment. Dapeng Laser (DPLASER) will be your top choice.

In summary, selecting the correct laser power for engraving different materials is key to achieving the best results in terms of clarity, depth, and speed. Whether you are working with metals, stainless steel, or plastics, understanding the power requirements for each material ensures efficient and precise marking. Explore our laser marking solutions to find the ideal machine that meets your engraving needs and maximizes your production efficiency.