Picosecond lasers are quickly becoming the preferred choice for precision material processing due to their ability to deliver ultra-short pulses with exceptional accuracy. Picosecond laser marking machines minimize heat generation, ensuring high-quality engraving, marking, micro-drilling, and cutting across various materials. Whether for creating intricate designs on stainless steel, cutting glass, or processing semiconductor components, picosecond lasers offer unmatched precision and efficiency. Notably, picosecond laser marking on stainless steel, which results in sharp contrast and fine, detailed markings, is one of the most common applications for picosecond laser marking.

Picosecond Laser Technology

A picosecond fiber laser is a type of fiber laser that generates laser pulses on the picosecond (10^-12 seconds) timescale. Its working principle combines fiber laser technology with ultrashort pulse technology, achieving highly concentrated laser energy and precise control.

Fiber Laser Technology

In fiber lasers, the optical fiber acts as the gain medium. Pump light excites rare-earth ions within the fiber, causing them to transition between energy levels and emit stimulated radiation. This radiation continuously reflects and amplifies within the fiber, ultimately outputting continuous or pulsed laser light. Fiber laser technology is known for its excellent beam quality, high efficiency, and compact structure, making it an ideal platform for generating picosecond pulses.

Ultrashort Pulse Technology

To generate ultrashort pulses in a picosecond fiber laser, techniques like Q-switching and mode-locking are commonly employed. Mode-locking is a method that synchronizes the phase of different longitudinal modes within the laser cavity to achieve pulse compression. When the phase difference between the cavity modes is constant, they coherently add up to form ultrashort pulses. By precisely controlling factors such as gain, loss, and dispersion within the cavity, picosecond fiber lasers are able to produce stable picosecond pulses with remarkable precision.

This combination of fiber laser and ultrashort pulse technologies allows picosecond lasers to be used for a wide range of applications, such as material processing, engraving, and micro-machining, where high precision and minimal heat damage are essential.

Building on the advanced principles of picosecond fiber laser technology, the pico-second laser marking & engraving machine leverages ultra-short pulses to deliver exceptional precision in material processing. With the ability to generate picosecond pulses, this machine ensures minimal heat generation, allowing for intricate, high-contrast markings and engravings on a variety of materials, including glass, plastics, and ceramics. This precision makes it an ideal choice for industries where fine detailing and minimal thermal impact are critical, such as micro cutting and drilling, semiconductor manufacturing, glass film cutting, as well as biomaterials and medical device production.

What is Picosecond Laser Marking Used For?

Material Processing

In precision manufacturing, picosecond fiber lasers are used for micro-machining processes such as drilling, cutting, welding, and marking. Their ultra-short pulses allow for precise energy deposition, reducing the heat-affected zone and recast layer, resulting in high-quality, high-precision processing. Additionally, picosecond fiber laser machining machines are suitable for processing hard and brittle materials like glass, ceramics and sapphire.

Laser Medical Applications

In the medical field, picosecond fiber lasers are widely used in ophthalmic surgeries, dermatological treatments, and cosmetic procedures. Their ultra-short pulses enable precise tissue cutting, minimizing thermal damage and bleeding, thus improving surgical accuracy and safety. For example, in ophthalmic surgeries, picosecond lasers are used for cataract removal, corneal transplants, and other delicate operations; in dermatology, they are used for skin treatments such as spot removal, wrinkle reduction, and hair removal.

Scientific Research

Picosecond fiber lasers also play a significant role in scientific research. They are used in cutting-edge fields such as nonlinear optics, ultrafast optics, and quantum optics, providing powerful tools for scientists to explore the mysteries of the material world. Moreover, picosecond fiber lasers are also applied in areas like radar, laser ranging, and laser-guided systems.

Picosecond Laser Material Processing

Picosecond lasers enable precise micro-machining with pulse energies of up to 250 µJ for cutting, drilling, or engraving. The ultra-short pulse duration helps avoid the creation of a heat-affected zone (HAZ) within the material. This technology allows for high-precision marking and micro-machining features with accuracies down to a few microns, even on fine and tough materials. The result is sharp-edged workpieces without micro-cracks, burning, or recast material. Infrared picosecond lasers offer high pulse energy, long lifespan, and exceptional processing efficiency, making them ideal for precise marking, drilling, cutting, and other applications.

- Versatility across Materials and Industries

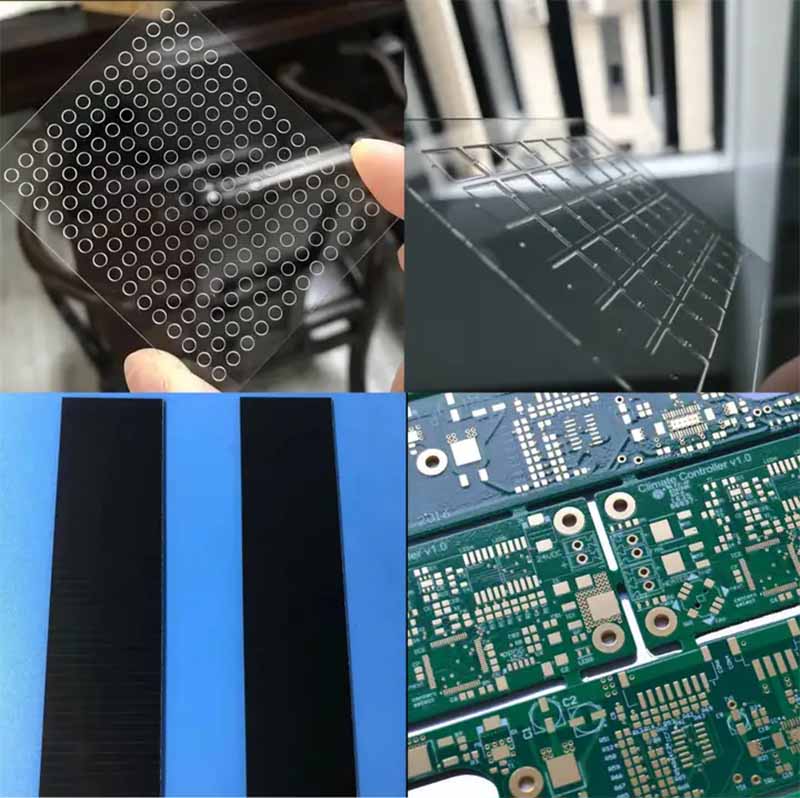

Picosecond lasers are suitable for a wide range of materials, including film cutting, ceramic drilling, metal blackening, glass cutting, and plastic marking. They are widely used in industries such as 3C electronics, semiconductors, solar energy, and precision manufacturing, offering high adaptability across various applications.

- Micro-machining and Laser Engraving

With their ultra-narrow pulse width and low thermal diffusion properties, picosecond lasers excel in applications such as metal blackening, plastic marking, and glass paint stripping. They ensure high contrast, fine detailing, and stability, outperforming traditional laser processes in terms of quality and efficiency.

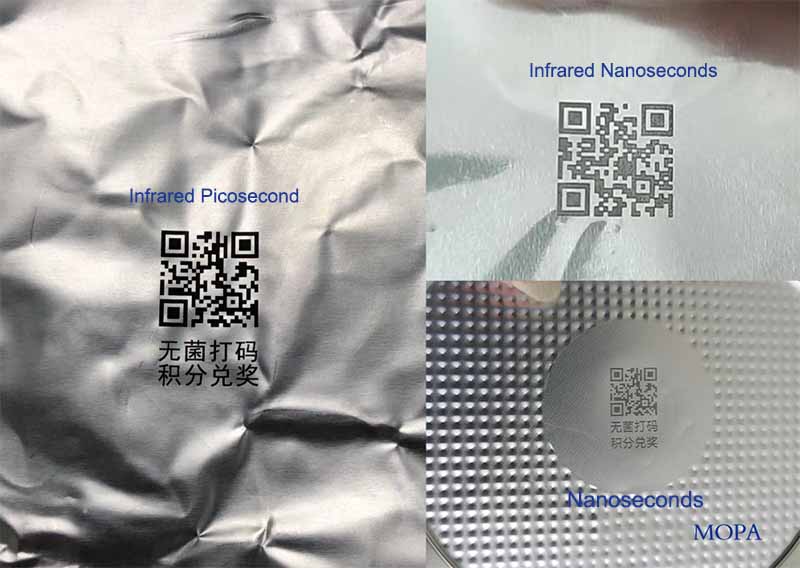

The image below shows the laser engraving effects on metal aluminum foil. It is evident that the infrared picosecond laser provides a much more contrast and clearer marking compared to the other lasers.

- Precision Drilling

In PCB (Printed Circuit Board) design, ceramic substrates are increasingly being used instead of conventional plastic substrates to achieve better heat dissipation. To connect electronic components, it is often necessary to drill hundreds of thousands of small holes, typically with diameters ranging from 40 to 100 μm. Ensuring that the substrate’s stability is not affected by heat input during the drilling process is crucial. This is where picosecond lasers become the ideal tool for micro-drilling precision holes on printed circuit boards (PCBs). The picosecond laser works in a “shock drilling” manner, ensuring uniformity in hole formation.

In addition to circuit boards, picosecond lasers can also be used for high-quality drilling in materials such as plastic films, semiconductors, metal films, and sapphire. These lasers are widely applied in industries such as mobile phone manufacturing, 3C electronics chips, FPC, PCB, and solar energy. Particularly for ultra-thin materials and glass drilling, picosecond lasers can achieve vertical cuts without tapering, ensuring high precision and superior quality.

- Glass Laser Cutting

With its ultra-short pulses and low heat diffusion characteristics, picosecond laser technology is highly effective in processing heat-sensitive and brittle materials such as glass, ceramics, metals, and thin films. In high-speed cutting modes, picosecond lasers ensure clean, straight edges, high verticality, and minimal internal damage, significantly enhancing processing quality. The ultra-fast pulses allow the laser to complete the cut before heat can diffuse into the surrounding material, preventing micro cracks and thermal damage. This makes picosecond lasers an advanced solution for high-precision glass cutting, widely used in electronics, optics, and high-end manufacturing fields.

- Precision Semiconductor Material Processing

In semiconductor manufacturing, picosecond lasers are primarily used for wafer cutting, marking, and micro-machining. Their high precision and low thermal impact help avoid thermal damage to semiconductor materials, improving yield rates. Additionally, picosecond lasers are used in photolithography processes to achieve smaller electronic component sizes. In thin-film solar cell production, picosecond lasers can accurately etch the desired patterns on the film without damaging its optical properties, ensuring efficient energy conversion. The no-thermal-damage, high-precision characteristics of picosecond lasers offer significant advantages in the semiconductor manufacturing industry, making them an ideal solution for improving thin-film solar cell processing quality.

- 3D Forming

Picosecond lasers achieve high-precision three-dimensional engraving through material ablation. Especially in the case of internal engraving, the laser has a very high degree of freedom to build complex three-dimensional structures inside and on the surface of the material. In polycrystalline diamond (PCD) tool manufacturing, picosecond lasers are the ideal processing tool for efficiently engraving milling cutter edges, chip grooves, and tooth profiles. The non-contact processing method ensures extremely high precision while avoiding material damage that may occur with traditional mechanical processing, making it the best solution for precision tool manufacturing.

- Excellent Results with Picosecond Black Laser Marking

Stainless Steel is an alloy composed of elements such as iron, chromium, nickel, and carbon. Using picosecond pulse lasers for black laser marking on stainless steel offers enhanced corrosion resistance. This type of marking remains clear and durable even in demanding environments, making it widely applicable in industries such as industrial manufacturing, medical devices, and consumer electronics.

Advantages of Picosecond Laser Marking on Stainless Steel and Aluminum

✅ Deep Black, High-Contrast Markings

Picosecond lasers can achieve long-lasting, high-quality deep black markings on materials like 316 stainless steel, meeting high standards for both visual clarity and durability.

✅ Enhanced Microscopic Structural Stability

The precise energy control of picosecond lasers minimizes thermal impact on the base material, effectively preserving the integrity of the microscopic structure of stainless steel. This enhances its corrosion resistance, outperforming traditional nanosecond and fiber laser processes.

✅ Uniform, Stable Oxidation Layer

The ultrafast picosecond pulses create an ultra-thin, stable oxidation layer on the material surface, improving corrosion resistance and ensuring lasting stability of the markings. Since the material is minimally affected by heat, its self-passivation mechanism remains intact. The marking originates from an optical nanostructure effect, not from an iron oxide layer, making it highly durable and resistant to fading even after multiple cleanings and passivation. The black marking created by picosecond lasers is considered non-corrosive.

✅ Pollution-Free, High-Quality Surface

The picosecond laser black marking process avoids molten residues and debris, producing clean, pollution-free marks with a shallow depth and minimal surface roughness.

✅ Low Thermal Impact

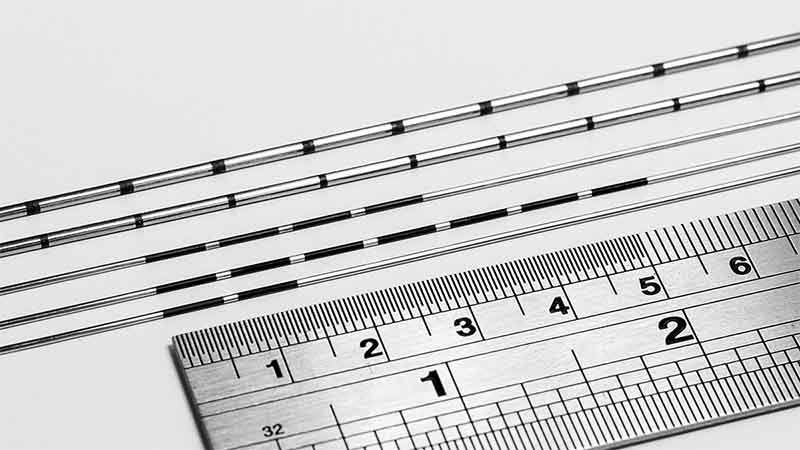

With minimal heat impact on the material, picosecond laser black marking is ideal for components that are sensitive to heat distortion, such as wires, pipes, thin sheets, and small implants. It will not alter the shape or performance of these parts.

With its exceptional processing precision and long-lasting marking results, picosecond laser black marking has become the preferred technology for stainless steel identification. It meets the stringent quality and reliability requirements of high-end manufacturing sectors such as medical devices and electronics.

Picosecond Laser Color Marking

One of the most prominent applications of picosecond lasers is metal marking and coloring. Ultrafast lasers can precisely control the microscopic structure of metal surfaces, making them rougher and increasing their light absorption, resulting in high-contrast black markings. These markings are not only clearly visible but also exhibit excellent weather resistance and corrosion resistance.

Additionally, by utilizing the precise thermal effects of picosecond lasers, different thicknesses of oxide layers can be formed on stainless steel and titanium surfaces, producing a range of vibrant colors. By finely adjusting the laser parameters, it is possible to achieve color markings in shades from blue and green to purple, offering highly customizable and visually striking results.

UV Picosecond Laser Marking and Cutting Machine for Materials

- PCB Industry Applications

Ideal for PCB laser depaneling, this machine can accurately cut FR4, reinforced steel sheets, FPC, rigid-flex boards, fiberglass boards, and more. It ensures no carbonization or burrs, improving PCB processing quality and production efficiency.

- Ceramic Substrate Cutting

Ceramic materials such as alumina and zirconia are often used as substrates in the electronics industry due to their excellent physical and chemical properties. The picosecond laser cutting machine easily handles cutting and perforating these ceramic substrates.

- Thin Film Material Cutting

The machine can directly cut PET films, PI films, and transparent film materials, while also supporting cutting, etching, and resistance tuning of conductive metal films like copper, aluminum, ITO, silver paste, FTO, etc., meeting the precision processing requirements of the electronics and display industries.

- Glass and Transparent Material Processing

It can precisely cut glass and thin films such as PI film or other coatings on the surface of glass without damaging the substrate. This feature is widely used in display panels, semiconductor, and optoelectronic industries.

- Thin Metal Precision Cutting

The machine offers high-precision cutting for copper foil, aluminum foil, stainless steel, and alloy materials thinner than 0.2mm, ensuring burr-free, low-carbonized, and undistorted cuts. It is particularly suitable for high-end manufacturing sectors like military parts and photovoltaic copper foil production.

Black and Color Marking on Stainless Steel

The picosecond laser is also widely used for black and color marking on stainless steel. By controlling the laser’s thermal effects, it can create high-contrast black markings as well as a variety of vibrant colors, such as blue, green, and purple. These markings are durable, corrosion-resistant, and ideal for applications that require both aesthetic and finesse labeling, commonly used in industries such as electronics, medical material, and luxury goods.

In conclusion, picosecond laser technology is revolutionizing industries by offering unparalleled precision and versatility in material processing. Whether it’s micro-machining, engraving, or high-quality cutting and drilling, picosecond lasers are transforming the execution of complex and delicate tasks—especially picosecond black laser marking, with the ability to create high-contrast, durable black markings. By minimizing heat-affected zones while achieving remarkable detail, picosecond lasers are becoming indispensable in fields such as semiconductor manufacturing, medical device production, and the creation of intricate designs on metals like stainless steel. Their exceptional performance is paving the way for innovative solutions in high-precision applications across a variety of industries.