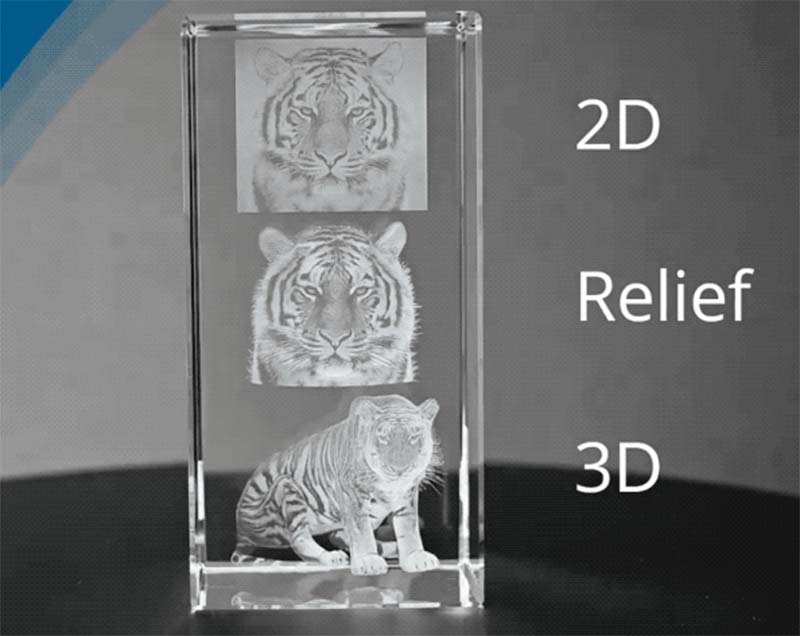

Laser engraving inside glass is an advanced processing technique that uses focused laser energy to create detailed 2D or 3D patterns inside transparent materials like glass or crystal. This non-contact, non-destructive method ensures the surface remains perfectly smooth while delivering high-definition, permanent results—ideal for applications ranging from industrial components to personalized gifts and luxury décor.

How Laser Internal Engraving Glass Works?

Laser internal engraving in glass works by precisely focusing a laser so that its energy density at specific internal points of the glass exceeds the damage threshold. This creates an instant high temperature that causes localized micro-fractures, forming tiny white points. These points combine to create a pattern inside the glass, while the outer structure remains completely intact.

1. Focusing the Laser Beam:

The laser beam is focused in such a way that its energy density stays below the damage threshold before entering the glass, but exceeds the threshold at the intended engraving area. This ensures that heat is generated only in the targeted internal regions, forming controlled markings.

2. Thermal Fracturing:

When the laser pulse is delivered to the designated area, it heats the glass rapidly, causing it to fracture at a microscopic level and form small white marks or engravings. By adjusting the laser’s energy and pulse parameters, the shape and depth of these marks can be precisely controlled.

3. Light Refraction and Reflection:

The position and shape of the engravings alter how light refracts and reflects inside the glass. This change in light behavior creates a three-dimensional visual effect, making the engraved images or text appear more vivid and realistic.

Advantages of Laser Etching Inside Glass

Environmentally Friendly

Laser internal engraving requires no chemicals or consumables during processing. It produces no dust, waste, or emissions, making it a truly clean and sustainable manufacturing method. The technology aligns with green manufacturing principles and modern environmental standards. Additionally, the equipment consumes relatively low energy, contributing to carbon reduction and energy efficiency.

High Precision and Fine Detail

Laser beams can be focused to the micron level, enabling extremely precise internal engraving. By controlling the laser’s position and depth, highly detailed and accurate 3D patterns can be created inside the glass. The resulting designs are rich in detail and depth, making them ideal for high-end art pieces and personalized keepsakes. Because the engraving occurs within the glass, the outer surface remains smooth and flawless, enhancing the visual appeal.

High Level of Automation

The entire process is digitally controlled, allowing graphics to be imported directly from design software. This enables smart, efficient production suitable for both mass manufacturing and customized orders. The technology integrates seamlessly with automated production lines, reducing manual labor and significantly boosting productivity.

Durability

Since the engravings are embedded within the glass, they are highly resistant to wear, fading, and environmental damage—much more durable than surface etching methods.

Customization Capability

Laser internal engraving can be tailored to meet specific customer requirements, allowing for unique and personalized designs. From simple text to intricate artistic patterns, the possibilities are highly versatile.

Wide Material Compatibility

This technology works with a range of transparent materials, including crystal glass, standard glass, and acrylic. It is not limited by shape or size, and requires no additional surface treatment, offering great flexibility for diverse product applications—from photographs and corporate logos to complex decorative elements.

Low Overall Cost

Although initial equipment investment may be high, the engraving process itself is fast, stable, and requires minimal post-processing. With low labor and material costs, the long-term operating cost is significantly reduced. High precision also means a high yield rate, minimizing rework and material waste.

Applications of 3D Engraving inside Glass

Laser internal engraving allows for the creation of unique and intricate 3D designs within glass, making it ideal for both artistic and functional applications. It is widely used in decorative settings such as bathrooms, glass processing centers, KTV lounges, bars, tea houses, and retail chains, as well as in the production of glass vases, lighting fixtures, tabletop ornaments, art pieces, and industrial glass components.

- Art and Collectibles

Thanks to its exceptional 3D visual depth and the elegant transparency of glass, laser-engraved artworks are highly valued by collectors. These pieces are often used for interior decoration, personalized gifts, and premium artistic displays—combining both aesthetic appeal and ornamental value.

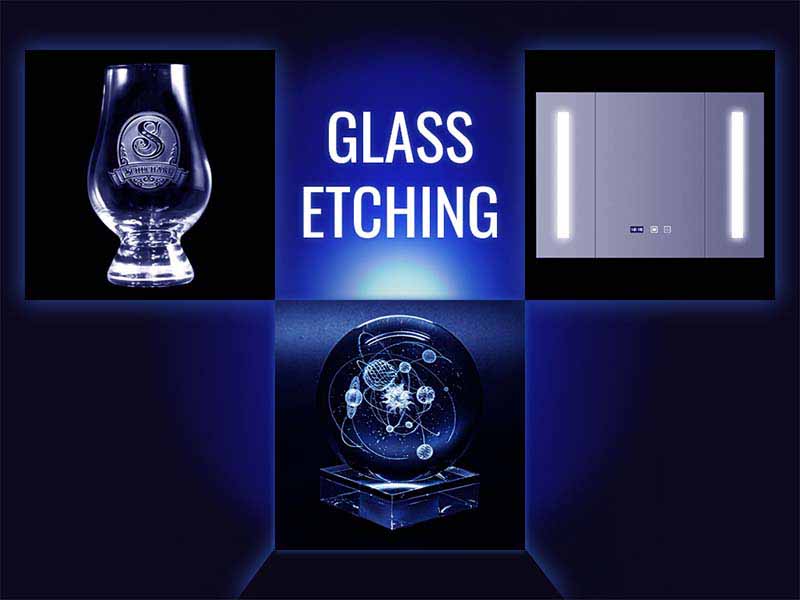

- Architectural and Interior Design

In architecture and interior spaces, laser-etched glass can be applied to facades, partitions, lighting elements, and decorative panels. Its ability to create dramatic light and shadow effects makes it a popular choice for enhancing ambiance in bathrooms, entertainment venues like KTV lounges and bars, tea restaurants, and branded retail environments.

- Creative Product Design

Designers frequently incorporate laser-engraved glass into household items, everyday glassware, and handmade crafts. This enables the development of highly customized, high-value products that elevate glass from a functional material to a medium for artistic and creative expression.

Will laser engraved glass inside patterns change color over time?

No. This is because the patterns are created by using high-energy laser pulses to produce micro-fractures within the interior of the glass—altering its internal structure rather than relying on pigments, dyes, or metal coatings.

As a result, the engraving is not affected by exposure to light, oxidation, or aging. As long as the glass material itself remains stable and intact, the clarity and three-dimensional effect of the pattern can last for over a decade, making it highly durable and long-lasting.

Laser Engraving Inside Glass Machine

The UV laser marking machine utilizes a 355nm wavelength, delivering high-energy photons that provide exceptional surface processing capabilities along with ultra-high precision and resolution. The laser beam is focused into a tiny spot, concentrating energy to trigger micro-explosions within the glass, forming tiny voids. By precisely controlling the position and depth of the laser, intricate internal patterns can be engraved. This laser marking equipment is widely used in both commercial and personalized applications, enabling the creation of exquisite and high-quality glass artworks with ease.

High-Precision UV Laser

Equipped with a 355nm ultraviolet laser, capable of ultra-fine focus—ideal for micro-processing. Ensures clean, sharp lines and well-defined patterns in every engraving.

Fast and Efficient Processing

With rapid laser response and smooth, stable operation, the machine is well-suited for mass production, significantly improving processing speed and output.

Minimal Thermal Impact

The short UV wavelength allows for highly focused energy with minimal heat diffusion. This effectively prevents glass deformation, cracking, or melting, ensuring consistent quality of finished products.

Zero Learning Curve

The machine features an intuitive interface and simple setup. With minimal training, users can begin producing high-quality engravings immediately.

Premium Engraving Results

Capable of performing ultra-precise engraving and cutting on both the surface and interior of glass. Produces visually striking, high-relief designs that meet the demands of premium customization.

Broad Material Compatibility

Suitable for a wide range of transparent materials including crystal glass, optical glass, and acrylic—making it ideal for diverse creative and manufacturing needs.

How to Use Laser 3D Engraving inside Glass

1. Design and Preparation

Before creating a laser-engraved glass piece, the artist begins with design and material selection. The desired pattern is created or imported using computer-aided design (CAD) software. At this stage, it’s also important to choose the appropriate type and quality of glass for the project.

2. Laser Parameter Setup

Based on the design specifications, the laser settings—such as power, pulse width, and focal depth—are adjusted. Once the parameters are properly configured, the engraving process can begin.

3. 3D Internal Engraving

The laser engraving machine emits pulses point by point along a predefined path, focusing the laser beam inside the glass to create micro fractures. These high-energy pulses generate controlled micro-explosions that form the internal structure of the pattern, resulting in rich textures and a striking 3D effect.

4. Post-Processing and Finishing

After the engraving is complete, artists may perform additional refinements to enhance the visual impact of the piece. This can include polishing, frosted finishes, or adding decorative elements—bringing out the full artistic potential of the engraved glass.

FAQ – Laser Engraving Inside Glass Machine

Q1: How long does it take to engrave a crystal?

A: Engraving typically takes anywhere from a few minutes to around 30 minutes, depending on the complexity of the design, the size of the crystal, and the laser settings used.

Q2: What image formats are supported?

A: We recommend using high-resolution images. Supported formats include BMP, JPG, PNG, TIF, DXF, DWG, STL, and others. For 3D engraving, STL or OBJ model files are preferred.

Q3: Can the machine engrave multiple crystals at once?

A: By default, the laser engraver is designed to engrave one crystal at a time. For batch production, optional upgrades such as multi-head laser systems or automated loading/unloading platforms can be used to engrave multiple pieces simultaneously, improving efficiency.

Q4: Will the engraved pattern fade or change color over time?

A: No. Laser internal engraving creates patterns by altering the internal structure of the glass, not by using pigments or coatings. Therefore, it is unaffected by light, oxidation, or environmental exposure. The pattern remains clear and vivid for many years.

Q5: What materials can be engraved?

A: The machine supports a variety of transparent materials, including crystal glass, optical glass, and acrylic. Engraving results may vary slightly between materials, so testing is recommended to achieve optimal results.

Q6: Will the glass crack during engraving?

A: No, not if the laser parameters are properly set. The system uses UV lasers with minimal thermal impact. The energy is tightly focused and precisely controlled, ensuring a stable and safe engraving process without cracking.

Q7: Can it engrave in color?

A: The laser internal engraving process itself can only create white or gray microdots within transparent glass—it does not support direct color engraving. However, colored lighting, illuminated bases, or printing technologies can be used to achieve vibrant visual effects.

Q8: Is the machine difficult to operate? Does it require professional staff?

A: Not at all. The machine comes with user-friendly software and an intuitive interface. Basic operations can be mastered with minimal training. It supports CAD file imports and offers pre-set parameter templates, making it accessible for both personal and business users.

In conclusion, the laser engraving inside glass machine represents a remarkable leap in precision marking and decorative craftsmanship. Its ability to create detailed, permanent 2D and 3D images within glass—without damaging the surface. Whether you’re working with crystal, glass, acrylic or specialty materials, investing in a professional-grade laser engraving inside glass machine can significantly enhance product value and design possibilities for both artistic and industrial applications.