What is laser 3d relief? Laser 3D relief is similar to 3D printing technology, as it also involves layer-by-layer processing of a model to shape the material along the Z-axis. However, unlike laser 3D printing, which is an additive manufacturing process, laser 3D relief is a subtractive process. It creates a raised, three-dimensional effect on the surface of an object through material removal.

Traditional Relief VS. 3D Relief Laser Engraving

Traditional hand engraving can produce exquisite and delicate reliefs with fine detail and high craftsmanship. However, it has some drawbacks: the quality of the carving is influenced by the skill of the craftsman, and the process can be time-consuming and inefficient. As a result, although high-quality outcomes are possible, the overall production speed tends to be slow.

In contrast, automated laser engraving offers extremely high speed and supports large-format engraving, making it particularly suitable for mass production. With 3D laser marking & engraving, it not only ensures high-quality engravings but also provides greater automation, making it widely used in the relief industry.

How Does 3D Relief Laser Marking Machine Work?

Laser relief is a sculpting process that uses a laser beam as the “tool” to cut or burn the material’s surface, creating a raised or recessed three-dimensional graphic. The core components of a laser relief engraving system include the laser source, galvanometer (galvo scanner), and other key elements.

In 3D laser relief engraving, the required 3D model is sliced using software, and then the laser is used to remove material layer by layer from a solid block to achieve the three-dimensional effect.

The process of 3D laser galvo engraving works by controlling the Z-axis dynamic motion in conjunction with the XY axes. As the number of layers changes, the Z-axis dynamically moves forward and backward to compensate for focus, ensuring consistent laser spot size throughout the process. In comparison, 3D laser galvo engraving is more efficient and precise as the Z-axis and XY axes collaborate seamlessly, with nearly microsecond-level focus compensation. Unlike external lifting platforms, this method offers higher efficiency and accuracy, making it more suitable for industrial-grade products.

High Efficiency:

The 3D dynamic axis works in full software coordination with the XY axis, with layer-focused compensation completed within microseconds, resulting in high efficiency. With the right configuration, its efficiency can match or even surpass that of CNC machines.

High Precision:

As the number of layers increases, the dynamic axis adjusts the focal length in real-time and continuously fine-tunes the laser spot. This ensures software-controlled focus consistency throughout the process, offering higher precision compared to traditional galvanometer-based systems.

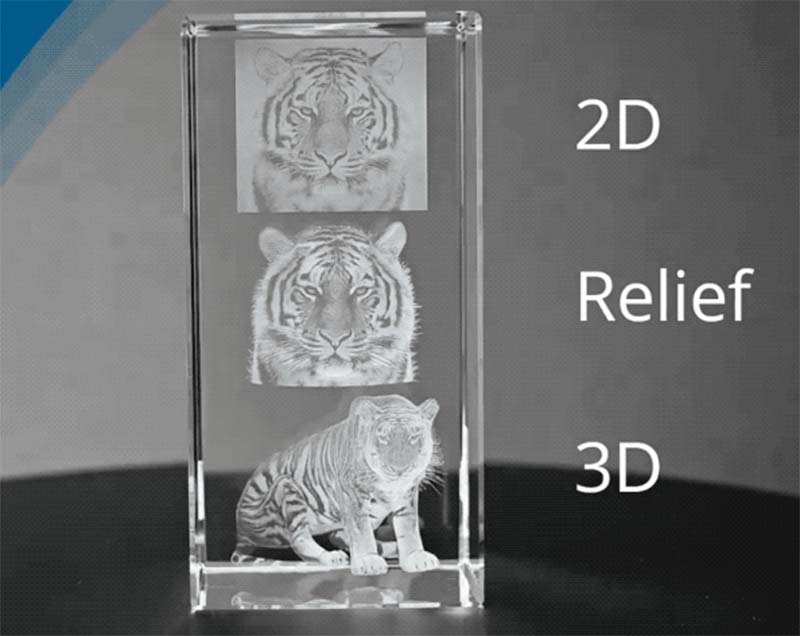

2D vs. 3D Laser Engraving

Processing Method:

2D Laser Marking: Primarily based on flat-plane laser cutting, the engraving process is two-dimensional. The laser typically cuts or marks the material’s surface, creating shallow depths. It is ideal for simpler reliefs or patterns.

3D Laser Relief: In contrast, 3D laser engraving allows for three-dimensional sculpting. The laser can penetrate the material’s surface and engrave at different depths and angles, creating more complex and sculptural relief effects.

Engraving Effect:

2D Laser Marking: Limited to flat processing, 2D laser engraving results in simpler relief effects with only variations in depth. The shapes tend to be more flat and less dimensional.

3D Laser Relief: Capable of engraving in multiple dimensions, 3D laser engraving can achieve finer depth, texture, and a more intricate, sculptural effect. The details are richer, and the overall result is more refined and complex.

Applications:

2D Laser Marking: Commonly used for simpler reliefs or flat cuts, such as logos, text, and basic patterns.

3D Laser Relief: Primarily used for intricate, detailed engravings that require complex, three-dimensional effects, such as high-precision art reliefs, molds, and sophisticated product designs.

What is Laser Deep Engraving Machine?

Laser deep engraving is a process that uses laser technology to perform deep engraving on the surface of an object. Compared to standard laser engraving, the focus of laser deep engraving is on repeatedly applying high-intensity laser beams to the material to achieve a deeper engraving effect. This method is commonly used on materials like metal, plastic, and wood, enabling the creation of more complex and three-dimensional patterns and text.

3D Laser Internal Engraving

Laser internal engraving on glass uses the focusing properties of the laser beam to concentrate the laser energy at specific points inside the glass. This causes a rapid rise in temperature at those points, forming tiny cavities or marks. These cavities or marks are arranged according to a predefined pattern, resulting in the intricate designs seen in laser internal engraving on glass.

Advantages of Laser Internal Engraving on Glass Crystal

High Precision Engraving: Laser engraving technology allows for extremely fine detailing on the surface or inside of glass, achieving micron-level precision. Whether its text, patterns, or intricate designs, laser engraving ensures highly detailed and precise results.

Non-Contact Processing: Since laser engraving doesn’t require physical contact with the glass surface, it prevents any physical damage to the glass and eliminates issues like wear, scratches, or deformation. This makes laser engraving ideal for fragile glass materials.

Versatile Design: Laser engraving can be applied not only to the surface of the glass but also inside it, creating rich, multi-layered, and unique three-dimensional effects. This ability to engrave internally opens up more creative design possibilities.

Environmentally Friendly & Pollution-Free: Laser internal engraving doesn’t require the use of chemicals or consumables, which avoids the production of waste materials common in traditional processing methods. The engraving process produces no harmful gases, dust, or noise pollution, making it more eco-friendly and safer for workers’ health compared to other traditional techniques.

Highly Automated: Laser internal engraving technology relies on computer-controlled precision, enabling fully automated production. This high level of automation reduces the complexity of manual operations, significantly increasing production efficiency. It also enhances product quality consistency, minimizing human error and ensuring stable results.

Laser glass internal engraving has widespread applications across multiple industries. It’s particularly popular in the deep processing of shower rooms, sliding doors, KTVs, bars, tea restaurants, and wall background, thanks to its unique aesthetic effects. Additionally, it’s used in everyday artistic products, photo displays, and increasingly chosen for both commercial and home décor.

Best 3D Laser Marking Machine for Deep Laser Engraving

- Deep Engraving

Traditional 2D laser engraving machines have inherent limitations when it comes to deep engraving. As the engraving process progresses, the laser focus shifts upward, causing a significant drop in laser energy, which negatively impacts both the engraving depth and efficiency. In contrast, 3D portable laser engraving machines effectively solve this problem, providing stable deep engraving results and ensuring consistent quality and efficiency.

- Color Engraving

The 3D portable laser engraving machine can achieve black, white, and even multi-color markings on the same surface, offering richer and more diverse effects. For instance, when engraving black marks on anodized aluminum or other metals, higher laser frequencies and specific defocus distances are required. Traditional 2D marking cannot produce complex multi-grayscale or multi-color effects. However, the 3D portable fiber laser engraving machine can deliver high-quality multi-color and multi-grayscale engravings, greatly expanding its range and depth of applications.

- Engraving on Uneven Surfaces

Traditional 2D laser engraving machines require the workpiece and the engraving surface to be on the same plane, limiting their ability to process irregular surfaces. The 3D portable laser engraving machine can perform single-pass marking even on surfaces with height differences, ensuring that the laser focus remains consistent, even on inclined or irregular surfaces, thereby preventing distortion or color variations.

- Engraving on Curved Surfaces of Different Heights

The 3D portable laser engraving machine can quickly adjust the laser focal length and beam position, enabling it to perform curved surface marking that traditional 2D laser engraving machines cannot. Whether it’s cylindrical, curved, or other complex surfaces, the machine can precisely engrave, meeting the needs for non-flat surface processing and broadening its application fields.

Laser 3D Engraving Document Types

Compatible with AutoCAD, CorelDraw, and Adobe Illustrator. It supports file formats such as AI, DXF, and PLT. 3D model files (STL format) can be used to create 3D raised or recessed relief effects.

Best Material for 3d Laser Relief

The 3d laser engraving machines we offer are durable and versatile, capable of marking almost any material or substrate. Most metals and non-metals can be used for relief engraving, including copper, aluminum, tool steel, silicon carbide, jade, wood, and more. The laser spot is finer than that of a traditional cutter, allowing for more detailed and precise engraving. As a result, laser relief engraving is widely used in industries such as crafts, specialized sectors, and mold manufacturing.

Applications of 3D Fiber Laser Engraving Machines

Jewelry and Accessories

3D laser relief technology is frequently used in custom jewelry, such as rings, pendants, and bracelets, allowing for the creation of intricate patterns and exquisite designs that give each piece a unique and personalized touch.

Signs and Nameplates:

Using 3D laser relief technology, it’s possible to create three-dimensional effects on company logos, office plaques, and industrial labels, making the text and graphics stand out more and enhancing their visual impact and recognition.

Brand and Product Identification:

This technology can also be applied to products such as tools, parts, and accessories for engraving serial numbers, detailed information, or brand logos, ensuring product traceability and enhancing brand uniqueness.

Decoration and Artistic Creations:

In the art field, 3D laser relief technology can be used to create metal sculptures, wall decorations, and personalized gifts, offering delicate relief effects that increase the artistic value and individuality of the pieces.

How to Use Laser Relief Machine for Deep Laser Engraving?

Before starting laser relief engraving, it’s essential to test and determine the most suitable parameters, including marking parameters, fill line spacing, and layer thickness.

- Adjusting Marking and Filling Parameters

When setting up the engraving, ensure that the markings produce a uniform matte texture on the surface. Only after achieving this can the engraving process continue effectively.

- Layer Thickness

Using the tested filling parameters, engrave 50 to 100 layers on the material. The total depth of the engraving divided by the number of layers gives the depth for each layer of the relief engraving. This is the “layer thickness” of the relief.

- Light Delay Settings

Test the sample and adjust the delay time to achieve the desired smoothness on the surface of the relief engraving. This ensures the surface is even and polished.

- Cleaning

During the engraving process, dust will accumulate. It’s important to clean the surface after every 3 to 5 layers of engraving. If dust is not cleaned regularly, it can accumulate and cause defects in the relief, leading to incomplete or irregular results.

3d curve surface laser relief machine In conclusion, the 3D relief laser marking machine creates intricate designs on a variety of materials, whether for artistic purposes or industrial applications. With our advanced 3D laser engraving machines, you can achieve exceptional precision and depth on various materials, from glass and acrylic to metal and stone. At Dapeng Laser, we offer customized 3D laser engraving solutions tailored to meet the unique needs of your business, ensuring unmatched quality, efficiency, and versatility in every project.