Driven by the demand for precision manufacturing and diverse work scenarios, the portable handheld laser welding machine has become a top choice for companies looking to upgrade, thanks to its ease of use, lower costs, and versatility. Unlike traditional large welding equipment, it reduces both upfront investment and ongoing maintenance expenses while easily adapting to different production environments. This enables businesses to improve efficiency, maintain welding quality, and boost competitiveness. If you’re a small business owner considering investing in a laser welder, read on to learn more.

Fiber laser welding machine is a precision welding device that uses a focused, high-energy laser beam to melt and securely join metals or thermoplastics. By concentrating the laser on the target weld area, it instantly generates intense heat that rapidly melts the contact surfaces, forming a strong weld upon cooling. With its minimal heat-affected zone, high welding accuracy, and clean, uniform welds, laser welding effectively reduces the need for post-processing such as grinding and alignment.

Why Choose Portable Laser Welder For Small Business?

Easy Operation

Portable laser welders are very easy to operate. Users simply need to set the laser power and other parameters according to the material and welding requirements. Although different brands may have slight variations in their controls, most machines can be mastered quickly with minimal training.

Affordable Pricing

Cost is a key consideration when choosing equipment. Currently, a good-quality portable laser welder generally costs a few thousand dollars. Prices can vary between brands and models due to differences in performance, features, and brand reputation. While well-known brands may have a higher upfront price, they often provide more stable welding results and better after-sales support.

Flexible and Convenient

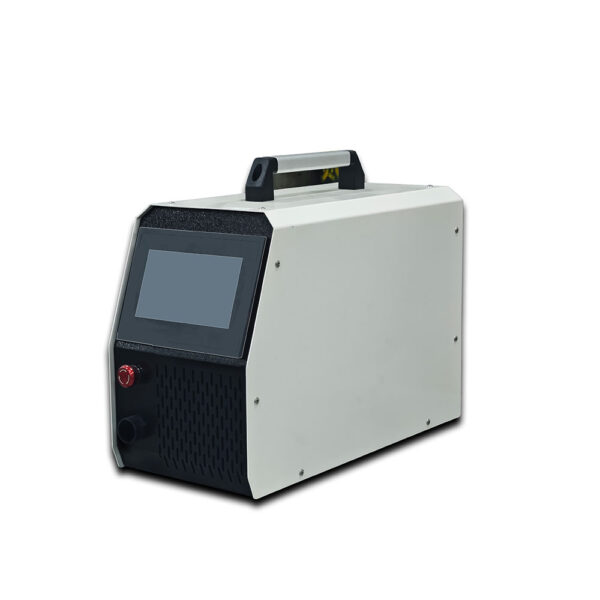

Compact and lightweight, portable laser welders are easy to move and adapt to different work environments. Many models feature air-cooling designs, keeping them affordable and low-maintenance. Their fast welding speeds also make them an ideal option for companies looking to upgrade or make their first investment in welding equipment.

Smart Control

Some high-end portable laser welders come equipped with intelligent control systems that automatically optimize welding parameters, significantly improving weld quality and efficiency. The user interface is clean and intuitive, allowing operators to easily set parameters via simple buttons or a touchscreen, making the entire process more user-friendly and efficient.

A portable small laser welding machine is compact yet powerful, affordable, and full of potential. It can support your hobby projects—enabling you to craft creative items in your spare time—or help you run a small metal shop with ease.

Laser Welder for Small Business

A right portable laser welding machine can help small businesses boost productivity and efficiency without a significant capital investment. By enhancing operations and supporting business growth, it eliminates unnecessary financial burden. Whether you’re a professional looking to improve production rates or a home user seeking a cost-effective solution, a small laser welder offers the perfect balance of precision, speed, and affordability.

Pricing and Cost

This 700W small laser welding machine price is around $2,000 and is well-suited for welding thin sheets (such as stainless steel or carbon steel up to 1 mm thick). It’s ideal for small startups, repair shops with limited investment, home use, and small repair tasks.

For welding very thin sheets (≤1 mm), you can choose a 1,000 W laser welder, which costs approximately $3,000 and offers more stable, visually appealing welds. For slightly thicker materials (1–3 mm), it’s recommended to go with a 1,000 W to 1,500 W model. For example, a DaPeng 1,500 W laser welder, priced around $4,000, provides greater welding strength and efficiency.

Powerful Portability

The compact and lightweight design makes these machines easier to transport and set up, allowing you to move easily between different work sites. Their small footprint also enables flexible operation in narrow or complex spaces, meeting diverse on-site welding requirements.

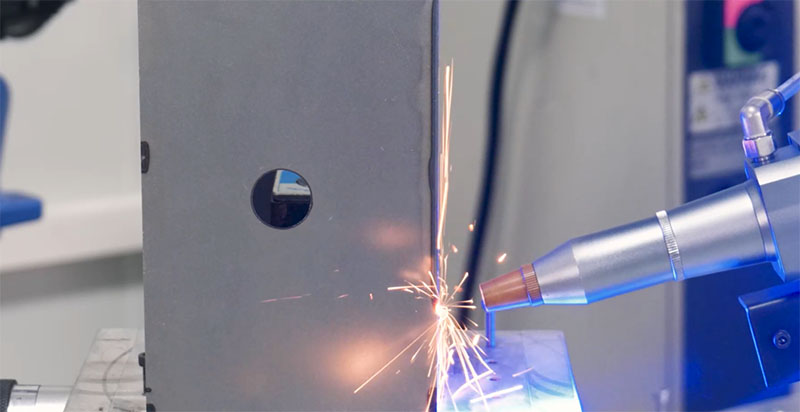

Exceptional Welding Technology

These portable handheld laser welding machines support multiple welding modes and offer adjustable parameters to suit different process requirements. Utilizing advanced laser technology, they produce smooth, uniform, and stable welds — making them especially suitable for metal fabrication and manufacturing, greatly improving final product quality.

Efficient Energy Usage

With stable, high-efficiency power output, the laser welder minimizes energy consumption and heat generation, helping businesses reduce energy costs, extend equipment lifespan, and achieve green, eco-friendly production.

Easy Operation and Quick Learning Curve

Designed with ergonomics in mind, the intuitive, user-friendly interface allows operators to master the machine without complicated training. Rapid setup and easy parameter adjustment significantly improve productivity and streamline workflow.

User-Friendly Interface

Straightforward controls and a clear display minimize training time and reduce the chance of errors, ensuring a smoother and more efficient user experience.

Wide Material Compatibility

Capable of welding a broad range of metals — including stainless steel, carbon steel, aluminum alloys, titanium alloys — as well as some plastics, the laser welder meets diverse manufacturing needs across industries, enabling businesses to explore new application areas and expand their market reach.

How to Choose Portable Laser Welding Machine for Small Business?

Assess Your Needs

First, clearly define your actual welding requirements, including the types and thicknesses of materials you will weld, as well as the desired welding precision and production efficiency. For small workshops, personal studios, or home use mainly handling simple tasks like thin metal sheets, an economical handheld laser welder with less than 1000W power and air-cooling design is a good choice. These machines are affordable, easy to operate, and effectively meet basic welding needs, helping users achieve welding automation at minimal cost.

Sample Testing Service

We offer professional welding testing support. Simply provide your samples and specific welding requirements, and our technical team will perform test welds using a portable laser welder to ensure the welding results meet or exceed your expectations. If the machine satisfies your process needs, we will provide a detailed test report and process parameters to help you quickly move into mass production.

Service and Technical Support

Timely Response to Minimize Downtime

During equipment use, operational or maintenance issues are inevitable. We provide prompt and efficient online technical support to help users quickly troubleshoot problems, minimizing equipment downtime and ensuring continuous production.

Training and Process Optimization

Based on your welding needs, we assist in fine-tuning key process parameters such as laser power and scanning speed. We also offer comprehensive training for operators covering equipment operation procedures and common troubleshooting techniques. This enables businesses to quickly master the equipment, maximize performance, and improve production efficiency.

Sample Testing to Verify Welding Quality

We offer free sample testing services using your workpieces. Key inspection points include weld appearance (surface smoothness, absence of pores and spatter), welding strength (e.g., pin weld tensile strength ≥ 5 N), and heat-affected zone analysis. This ensures welding quality meets standards without compromising component performance (such as capacitors or IC chips).

On-Site Visit to Assess Manufacturing Capability

You are welcome to visit our facility to tour the equipment production process and quality control stages. Experiencing our manufacturing capacity and quality standards firsthand provides valuable insights when evaluating equipment reliability and the overall strength of our company.

Portable Handheld Laser Welding Machine (FAQ)

Q: What factors should be considered when choosing the best small laser welding machine?

A: When selecting a small laser welder, key factors include welding power, laser type, portability, welding precision, and ease of operation. Additionally, consider the range of compatible materials, cooling method, after-sales support, and budget to ensure the machine meets your practical needs with good stability and durability.

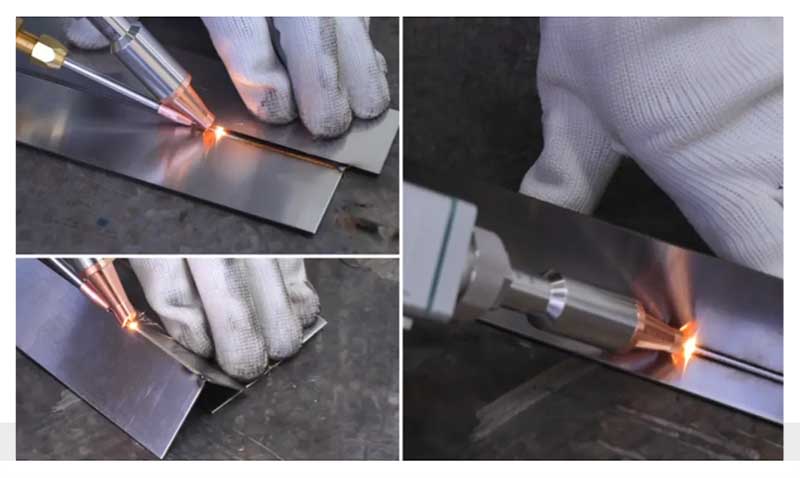

Q: What is the role of the handheld welding gun in a portable laser welder?

A: The welding gun is a critical component that guides the laser beam precisely onto the welding area. It typically integrates the optical system, gas protection, and cooling system to ensure stable beam delivery, concentrated heat, and high welding quality, while also ensuring operator safety and comfort.

Q: Can a handheld fiber laser welding machine perform both welding and cutting?

A: Yes, handheld fiber laser welding machine can perform both welding and cutting, depending on the specific model and features. This usually requires a compatible all-in-one control system and welding gun setup.

Q: What are the advantages of low-power small laser welders?

A: Low-power welders are compact and lightweight, making them easy to carry and operate, especially in confined spaces or on-site jobs. They consume less power, require simple maintenance, and are suitable for metal welding and spot welding tasks. Their lower investment cost makes them ideal for startups and small workshops.

Q: What are the common applications of portable laser welders?

A: Portable laser welders are commonly used for metal repair work, machinery manufacturing, door and window welding, and other tasks where heavy welding equipment is impractical to use.

In summary, choosing the right portable laser welder can make a significant difference for small businesses aiming to improve productivity and product quality without breaking the bank. Understanding the small laser welding machine price alongside features and performance will help you make a smart investment that supports your growth and operational needs. If you want to explore affordable, reliable small welding solutions, feel free to reach out for expert advice and personalized recommendations.