In modern industrial manufacturing, as materials and structures become increasingly complex, traditional welding processes often struggle to meet the demands of many challenging tasks. High power laser welding machine, with its exceptional precision, efficiency, minimal heat input, and deep penetration, have emerged as the go-to solution for these challenges. This article will explore the advantages of high power laser welding machine and introduce Dapeng Laser’s newly launched 6000W handheld laser welding machine.

Laser welding machines work by generating a high-energy-density laser beam with a laser source, which is then focused and directed by an optical system onto the surface or interior of the material. The targeted area rapidly heats up to melting or even vaporization in a very short time, fusing the material together. Thanks to the extremely high power density and precise focus of the laser beam, the heat-affected zone is kept to a minimum, greatly reducing thermal damage and deformation of the material.

Advantages of High Power Laser Welding Machine

- High-Precision Welding

High-power laser welding machines leverage advanced optical and control systems to achieve micrometer-level welding accuracy. This ensures perfectly aligned welds, minimizes defects, and greatly improves overall weld quality.

- High Production Efficiency

Laser welding is exceptionally fast, allowing large volumes of welding work to be completed in a short time and significantly boosting production efficiency. Moreover, with no need for preheating or post-weld heat treatment, production cycles are further shortened.

- Low Heat Input and Minimal Deformation

Laser welding produces a very low heat input with a small heat-affected zone, which significantly reduces thermal distortion and residual stress. This improves the dimensional accuracy and surface quality of the weld, making it especially valuable for precision components and large-scale equipment manufacturing — ensuring better assembly accuracy and overall product performance.

- Powerful Penetration Capacity

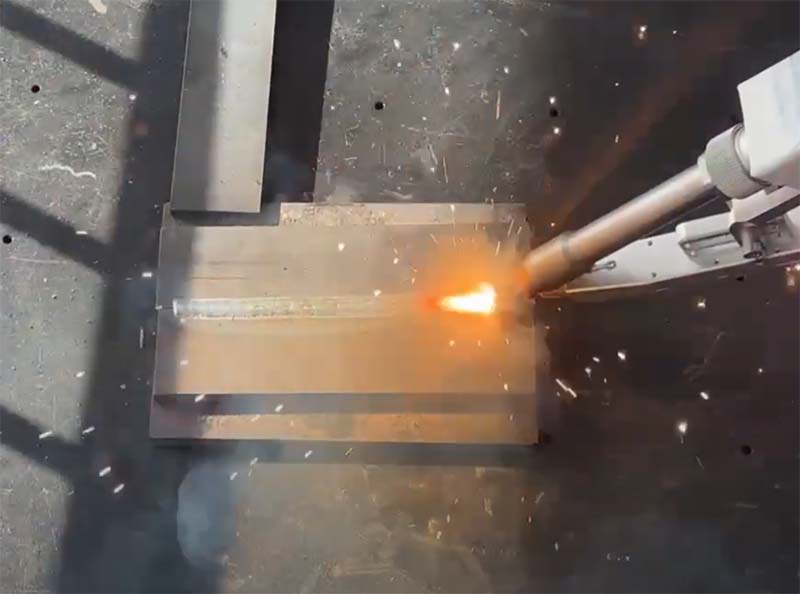

A 6000W laser welding machine can output several kilowatts of power, allowing it to easily weld thick and heavy metals and achieve deep-penetration welds at high speed and superior quality. Even for carbon steel over 12 mm thick, high-power laser welding can quickly enable double-sided welding. In large steel structure fabrication, single-pass welds reduce the number of joints and weld passes, significantly cutting labor time and costs.

- High Degree of Automation and Intelligence

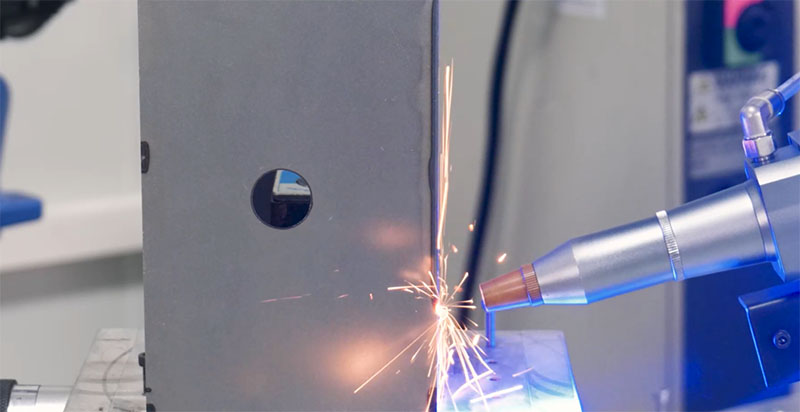

High-power laser welding machines can integrate seamlessly with robots and automated production lines, enabling fully automated operations. Equipped with intelligent control systems and programmable welding paths, these machines automatically optimize parameters for different welding tasks. This greatly enhances weld consistency and stability while reducing labor requirements and overall production costs.

Continuous Laser Welding vs. Pulsed Laser Welding

Continuous Laser Welding

Continuous laser welding typically uses power ratings above 500W, and the latest 6000W fiber laser welding machines uses a 6000 W laser sources. It’s especially suitable for welding sheet metal ≥ 1 mm in thickness. The process relies on the keyhole effect, allowing for deep-penetration welding with a depth-to-width ratio greater than 5:1. Its high speed, small heat-affected zone, and minimal distortion make continuous laser welding ideal for industries like machinery, automotive, and shipbuilding — significantly improving productivity and weld quality.

Pulsed Laser Welding

Pulsed laser welding is better suited for thin-walled metals ≤ 1 mm thick. The process is dominated by heat conduction, where short laser pulses heat the surface and gradually transfer energy into the material. By precisely controlling parameters such as pulse shape, width, peak power, and frequency, it is possible to produce strong, accurate welds with minimal heat-affected zones and distortion. This method is widely used in electronics, 3C product casings, lithium batteries, and mold repair — effectively reducing thermal damage and ensuring high welding precision.

Applications of 6000W High Power Laser Welders

Automotive Industry

Laser welding was first adopted in automotive production in 1999, with SAIC Volkswagen leading its implementation for car body assembly. Compared to traditional welding, laser welding offers significant advantages — including faster welding speeds, lower deformation, superior weld sealing and reliability, and a high degree of automation. These benefits have led to its widespread use in automotive body and component manufacturing.

Shipbuilding and Machinery

In shipbuilding, laser welding is commonly used for hull sections, bulkheads, and mechanical components such as fixtures and molds. Its high-speed, high-quality welds enhance both the strength and sealing performance of the structures, improving overall production efficiency and weld integrity.

Heavy Bridge Construction

For large-scale bridge projects, laser welding provides the high efficiency and precision required for welding steel beams and frame structures. This ensures secure, durable welds that meet strict safety and longevity requirements — making it a dependable choice for major bridge engineering.

New Energy Battery Applications

Thanks to its small heat-affected zone, minimal distortion, and superior precision and weld quality, laser welding is widely used in the fabrication of new energy battery cells and modules. This helps enhance battery performance and consistency across large-scale production.

3C Industry Applications

Laser welding systems — comprising lasers, welding heads, and automated production lines — offer exceptional control and accuracy. They are extensively applied in the 3C sector for welding metal frames, connectors, electronic device casings, hardware fittings, structural parts, circuit boards, battery packs, sensors, and other small components. This improves production efficiency, product consistency, and overall quality.

Cabinet Industry Applications

In the cabinet industry, high power 6000 W laser welders are mainly used for high-speed, high-precision welding of stainless steel and aluminum sheets. The process yields clean, strong welds with minimal distortion and less need for post-weld grinding, allowing cabinet manufacturers to reduce costs while increasing automation and delivering high-quality products.

6000W Handheld Laser Welding Machine

Compact and Integrated Design

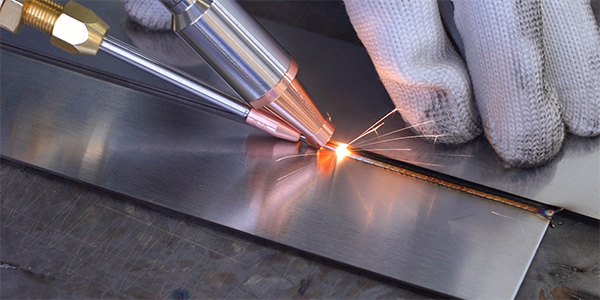

The 6000W handheld fiber laser welder integrates a fiber laser source, cooling system, handheld welding gun, automatic wire feeder, and intelligent control system, representing the forefront of modern laser welding technology. Featuring non-contact welding, the handheld torch directly welds the workpiece, making it ideal for complex shapes, large sizes, or parts difficult to fix in position. It excels in welding tasks within tight spaces and challenging angles.

Outstanding Welding Capability

This high-power 6000W laser welder delivers exceptional performance across a variety of metals including carbon steel, stainless steel, galvanized steel, aluminum, and copper. It produces welds with a high depth-to-width ratio and narrow seam width, offering easy operation, fast welding speeds, and stable, efficient performance. It can handle plate thicknesses from 3 to 10 mm, producing aesthetically pleasing, high-quality welds with strong penetration. It is widely used in cabinetry manufacturing to enhance both quality and productivity.

Versatile Welding Processes

Supports a broad range of welding techniques including butt welding, fillet welding, vertical welding, overlap welding, sealing welding, heat conduction welding, deep penetration welding, spot welding, continuous welding, and fish scale welding, meeting diverse welding scenarios and process requirements.

4-in-1 Multifunctional Integration

This device combines welding, cutting, cleaning, and seam treatment in one unit, enabling seamless switching between different processes. This integration improves production efficiency and processing quality, allowing multi-step operations to be completed smoothly. It significantly reduces equipment investment and operation time, fulfilling complex manufacturing demands.

Compact Footprint and Flexibility

Featuring an all-in-one laser welding machine is equipped with mobile casters for easy movement and flexible adjustment of the working position on-site. The handheld welding gun, paired with optional transmission fibers, breaks free from traditional workbench limitations, enabling welding on virtually any part or angle of the workpiece—especially ideal for complex joint structures.

Continuous Operation

Engineered for industrial-grade, around-the-clock use, the system’s full water-cooling ensures low operating temperatures, supporting uninterrupted 24/7 operation.

Low Operating and Maintenance Costs

With low power consumption, a compact structure, and straightforward routine maintenance, the equipment boasts a long service life and user-friendly operation. It requires no expensive consumables, significantly reducing production costs and enhancing long-term economic benefits for enterprises.

Application Limitations and Future

Currently, this machine easily replaces TIG welding for plates thicker than 10 mm, improving production efficiency and weld quality. However, for ultra-thick plates of 20~30 mm, there is still room for improvement in welding strength and portability. With ongoing advances in laser power and welding technologies, handheld laser welders are expected to expand their capabilities to thicker materials and more complex structures, unlocking broader applications across manufacturing industries.

Support and Service Guarantee

For our metal laser welding machines, we provide comprehensive technical support and after-sales services. Our team consists of experienced laser welding experts and technicians dedicated to ensuring your equipment operates reliably and efficiently.

We commit to responding promptly to your needs and offering professional technical guidance to help you optimize device performance. With a well-stocked spare parts inventory, we ensure continuous and smooth machine operation. Regular maintenance services help prevent potential issues and keep your equipment in peak condition.

Packaging and Shipping Information

The aluminum laser welding machine is carefully packaged using professional materials to protect the equipment and accessories during transit. Each shipment includes a detailed packing list clearly itemizing all contents for easy customer verification.

The packaging is sturdy and designed to prevent damage from shocks or impacts during transport. External labels feature clear shipping instructions and the sender’s contact information to facilitate tracking and communication.

6000W Metal Laser Welding Machine (FAQ)

Q1: What brand of laser source does this welding machine use?

A: The laser welding machine can be equipped with laser sources from Max, Raycus, or Keplin, offering a maximum output power of up to 6000W to meet diverse welding requirements.

Q2: What thickness of metal can this laser welding machine weld?

A: It can weld up to 12 mm steel or 8 mm aluminum in a single pass, providing stronger welds with fewer passes and faster operation. For thicker materials (20~30 mm), there are some limitations, and the maximum thickness depends on the material type and welding process.

Q3: What types of metals can this machine weld?

A: The equipment supports high-quality welding of various metals, including carbon steel, stainless steel, galvanized steel, aluminum, and copper.

Q4: What is the welding speed of this machine?

A: Welding speed varies depending on material type and thickness, but it generally achieves several meters per minute, significantly boosting production efficiency.

Q5: Where is this laser welding machine manufactured?

A: This 6000W laser welding machine is manufactured in Shenzhen, China. It features a professionally customized fixture system to ensure precise and stable workpiece positioning, enhancing weld consistency and quality. The equipment also supports integration with automated production lines for automated welding operations.

In conclusion, a laser welding machine 6000W is an invaluable investment for businesses looking to enhance their welding capabilities with speed, precision, and consistent performance. Its powerful output, combined with advanced features like handheld flexibility and stable long-term operation, ensures optimal results across a broad range of materials. Whether you’re in manufacturing, automotive, or heavy industry, choosing the right 6000W laser welder can improve your production efficiency and help you stay competitive in a rapidly evolving market. Let us help you find the perfect solution to meet your specific welding requirements.