By 2024, the global market for handheld laser welding machines has reached approximately 876 million USD, with around 160,000 units sold. Among them, handheld air cooled laser welding machine has seen a significant rise in market share—especially in models under 1500W. In fact, air cooling has now surpassed water cooling as the preferred solution in this power segment. As demand grows for compact, low-maintenance systems, the air cooled laser welding machine is becoming the mainstream choice in today’s competitive laser welding industry. But what’s driving this shift, and why is air cooling outperforming traditional water-cooled systems?

How Does an Air-Cooled Laser Welding Machine Work?

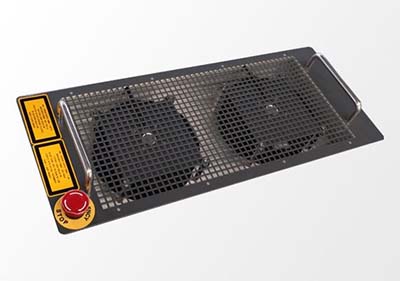

A portable air cooled laser welding machine uses air to cool the laser source during operation. This modular and compact welding system integrates the laser generator, welding head, cooling unit, and control system into a single unit.

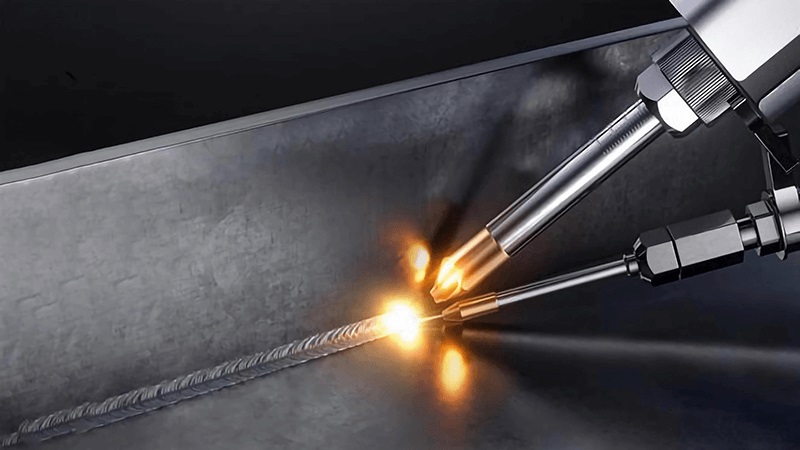

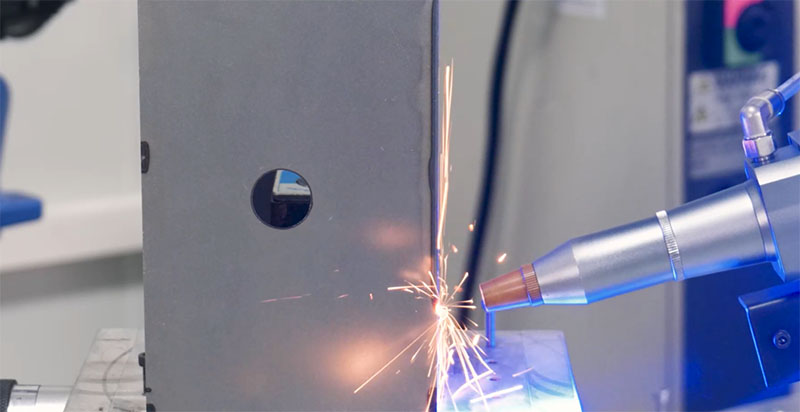

The laser beam is generated by the laser source and transmitted through a fiber optic cable to the welding head, where it is focused onto the workpiece surface to perform welding. The ergonomically designed handheld welding gun is easy to grip and allows angle adjustment for greater flexibility. An internal fan provides efficient air cooling to prevent overheating. The control system allows precise adjustment of parameters such as laser power and pulse frequency, ensuring compatibility with various welding tasks.

Compared to the water-cooling systems, air-cooling offers easier installation and greater portability. The handheld design of the air-cooled laser welding machine removes workspace limitations, allowing for flexible welding of both sheet and tube materials. Its affordable price makes it accessible for small businesses, striking a balance between performance and cost, and making it a highly cost-effective choice.

Advantages of Handheld Air Cooled Laser Welding Machine

Lightweight and Portable, Easy Maintenance

The portable air-cooled laser welding machine replaces traditional water-cooling systems with a fan and heat sink design, weighing only 60% of comparable water-cooled units. It’s compact and easy to carry, requiring no space for a water tank—ideal for small workshops or crowded production lines. Its cordless, fully air-cooled system eliminates the need for coolant refills, water quality monitoring, and antifreeze in winter. In cold regions, this significantly reduces costs associated with water-cooling systems. The machine starts instantly, with no preheating required.

Simple Operation

The best air cooled laser welding machine offers multiple welding modes and features a user-friendly human-machine interface. Users can easily adjust parameters, use preset libraries, and switch between functions. Even beginners can get started quickly, reducing training time to just one hour and enabling efficient “power on and weld” operation.

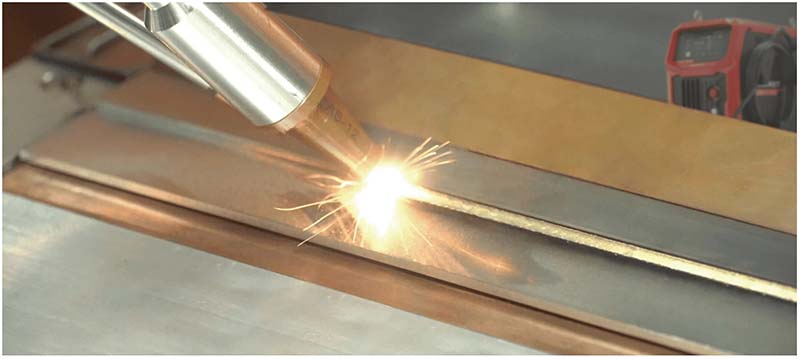

High Welding Speed

Compared to traditional manual arc welding, the air-cooled laser welder is 2~10 times faster. For instance, it can weld 1mm thick steel at speeds of up to 5 meters per minute, significantly boosting production efficiency.

Neat and Precise Welds

Weld seams can be controlled to a width of just 0.1–0.3 mm, with surface roughness up to Ra ≤ 0.1 μm, requiring no post-processing.

Cost-Effective, Boosts Efficiency

Initial procurement costs are reduced by over 30% due to the elimination of a separate water chiller. With no water pumps or coolant involved, power consumption is lower, making it more economical for long-term use. Its low failure rate and minimal maintenance needs translate into substantial economic benefits for businesses.

Eco-Friendly, Energy-Efficient, and Reliable

Using purely physical air cooling, the air-cooled laser welding system consumes and emits no coolant, aligning with green manufacturing trends. In application under 1000W, the intelligent temperature control system keeps core components within a safe range, enabling 24/7 stable operation with welding performance comparable to water-cooled systems.

Versatile Applications

Perfectly suited for welding thin metal parts like metal component repairs, appliance panels, and jewelry, it supports over 10 common metals including stainless steel and copper alloys. From precision welding in frame to rapid joining of furniture metal parts, it handles diverse production tasks with ease.

Plug-and-Play

No professional installation is required—one person can set up the air cooling laser welding machine in just 30 minutes. Simply plug it in to begin production. With no water pumps, hoses, or other easily worn components, maintenance frequency is reduced by 80%, and fault response time is under one hour, maximizing production continuity.

Air Cooled Laser Welder Application Scenarios

Thanks to its high efficiency and flexibility, the compact air-cooled laser welding machine is widely used across various complex welding applications. It is ideal for irregular and intricate welding tasks in industries such as kitchen cabinets and bathroom fixtures, staircases and elevators, shelving, stainless steel doors and window railings, and electrical cabinet hardware fabrication.

For small processing businesses, maker studios, and mobile repair operations—where equipment flexibility and cost control are crucial—the machine’s lightweight, portable design and quick deployment deliver maximum value. It significantly improves productivity and welding quality in hardware manufacturing and jewelry production.

It supports welding of various metals ranging from 0.1 to 4 mm in thickness, including carbon steel, stainless steel, galvanized steel, aluminum alloys, and brass. With a stable weld penetration depth of 0.5 to 3 mm, the machine provides a reliable solution for a wide range of welding needs.

DP Laser’s Newest Air-Cooled Laser Welding Machine – The Best Air Cooled Laser Welding Machine in 2025

In high-standard welding fields such as shipbuilding, laser welding is gradually becoming the industry standard due to its superior sealing, tensile strength, and flaw detection performance. Traditional welding processes rely heavily on the welder’s experience to achieve high-quality welds, making it difficult to meet the demands of standardized and mass production. Laser welding technology, with its stable formation and high efficiency, is emerging as an ideal alternative.

However, traditional water-cooled handheld welders are often bulky and lack portability. To address this, DP Laser has launched a new air-cooled handheld laser welding machine, offering a comprehensive upgrade in user experience and industrial efficiency.

Air-Cooled System – Lightweight and Portable

This air-cooled laser welding system features a purely air-cooled system, eliminating the need for an external water tank. The entire machine weighs ≤30 kg, and the welding gun weighs only 0.53 kg, allowing a single person to carry and operate it with ease. It supports stable 24/7 continuous operation, with a weld penetration depth of up to 4 mm, suitable for a wide range of metal materials including stainless steel, carbon steel, and aluminum alloy.

Smart Control System – Zero Learning to Start Welding

Equipped with a fully closed-loop welding control system, the machine enables multi-dimensional real-time monitoring and fault prediction. The built-in high-precision temperature control module dynamically tracks the status of key components, effectively reducing failure rates and maintenance costs while significantly boosting production efficiency.

With an integrated process parameter library, users simply select the material type and thickness, and it automatically matches the optimal welding parameters. This “plug-and-play” functionality dramatically lowers the operational threshold and helps enterprises rapidly replicate standardized processes at scale.

Professional Welds – One-Pass Perfection

Thanks to advanced laser welding technology, the laser welding machine easily produces uniform, aesthetically pleasing, and robust fish-scale welds. With a minimal heat-affected zone, low deformation, and stable formation, it ensures consistently high welding quality—so even beginners can achieve professional-grade results.

Ergonomic Welding Gun – Fatigue-Free

The next-generation handheld welding gun is made of high-strength, lightweight materials, with an optimized structure and balanced center of gravity. It offers excellent interference resistance and ergonomic comfort. Weighing only 530g, it supports prolonged continuous operation, enabling welders to handle intensive workloads with ease.

How to Choose a Handheld Air Cooled Laser Welding Machine?

When selecting an air-cooled fiber laser welding machine, consider your actual needs carefully:

- Laser Power: Choose based on material thickness and welding efficiency. 1000W suits thin plates (1–3 mm), while high power 1500W is better for thicker materials (3–6 mm).

- Welding Gun Design: Ergonomic design affects operational comfort and efficiency, especially for prolonged use. Ensure the design supports ease of handling over long periods.

- Control System Features: The precision of parameter adjustments determines weld quality. A flexible control system that adapts to different welding processes is essential.

- Reliability and After-Sales Service: The stability of the laser welding equipment impacts production continuity. Comprehensive after-sales support helps reduce maintenance costs and downtime risks.

Top Brand of Air-Cooled Laser Welding Machines 2025

DP Laser:

DP Laser’s compact air-cooled handheld laser welding machines stand out for their strong stability, small size, and lightweight design. Featuring next-generation fiber lasers and proprietary welding heads, these machines offer simple operation, aesthetically pleasing welds, and fast welding speeds. They can effectively replace traditional processes like TIG and arc welding in some thin plate applications.

Han’s Laser (Han’s Laser):

Founded in 1996, Han’s Laser is a major industrial laser equipment manufacturer providing comprehensive laser processing solutions and supporting facilities. Their product range includes laser marking machines and laser welding machines. With mature technology in laser welding and strong market recognition, they are a trusted leader in the field.

HGTECH (Huagong Laser):

Part of Huagong Technology, HGTECH offers a wide laser equipment lineup. Their ultrafast precision laser processing equipment for brittle materials has earned the title of “Single Champion Product” by the Ministry of Industry and Information Technology. They provide comprehensive laser and intelligent equipment solutions for manufacturing customers, with their air-cooled laser welding machines known for high performance and quality.

Hymson Laser:

Since 2008, Hymson has specialized in laser and automation technologies, offering products such as lithium battery automation and air-cooled UV laser equipment. Serving industries like lithium batteries and 3C electronics, they provide efficient integrated solutions. Their air-cooled laser welding machines hold technical advantages and a solid market share.

Lianying Laser:

Shenzhen Lianying Laser Co., Ltd. specializes in laser welding and has strong R&D capabilities in this area. Their air-cooled laser welding machines meet diverse welding process requirements and are widely used in industries such as new energy and automotive manufacturing, enjoying high market recognition.

Max Laser:

As an independently operated subsidiary under the fiber laser leader MAX Laser, Max Laser targets the tool-grade laser market. Their Hongtong series air-cooled handheld laser welders have topped global sales for three consecutive years. The flagship Hongtong K1M is the world’s first handheld laser welding device integrating laser equipment, wire feeding, and nitrogen generation systems—advanced technology combined with lightweight portability.

Kirinlaser:

Focused on laser applications, Kirinlaser launched the air-cooled laser welder, the first laser perfectly adapted for handheld laser welding devices. It features single-pump output to reduce energy loss and intelligent monitoring, with power up to 700W and a peak output of 750W, injecting new technological vitality into the air-cooled laser welding machine market.

IPG Photonics:

As a world-leading manufacturer of fiber lasers, IPG Photonics’ laser welding equipment is renowned for its high power, high efficiency, and stability. Widely used in automotive manufacturing, electronics, components, and other fields, their air-cooled laser welding machines offer reliable performance and advanced technology.

JPT Laser:

JPT Laser focuses on the research and manufacture of fiber lasers. Their air-cooled laser welding machines are favored by customers in electronics manufacturing and precision industries due to their cost-effectiveness and excellent welding quality.

Air-Cooled Laser Welding Machine Price

The price of air-cooled laser welding machines varies significantly depending on factors such as laser power, brand, configuration, and additional functionalities. Entry-level models with lower power (around 500W to 1000W) typically start from around $2,000 to $3,000 USD, making them accessible for small applications or lightweight industrial use.

Last but not least, when considering an air cooled laser welding machine, price plays a crucial role alongside performance and reliability. The air cooled laser welding machine price offers excellent value by reducing maintenance costs and simplifying operation, especially for start-up or small businesses. The rising popularity of air cooled handheld laser welding machines shows their clear advantages in efficiency, portability, and cost-effectiveness, especially for 1000W and 1500W power. As industry demands continue to evolve, choosing the right air cooled handheld laser welder can significantly boost productivity while minimizing maintenance cost.