In the world of stone processing and decorative craftsmanship, precision and detail are everything. Traditional stone engraving methods often fall short when it comes to achieving fine textures and intricate patterns, especially on hard materials like granite and marble. This is where the 3D laser engraving machine for stone stands out. Designed for high-precision, non-contact engraving, these machines can create detailed reliefs, complex images, and deep textures directly on stone surfaces.

Can Laser Cut Stone?

Yes, laser cutting and engraving can be applied to various types of stone, including granite, marble, slate, and sandstone. It allows for the creation of permanent markings, patterns, text, and images on the surface. Laser engraving on stone offers a wide range of design possibilities. The laser beam interacts with the stone’s surface to create contrast and depth, making it an ideal choice for producing monuments, decorative items, signage, and architectural elements.

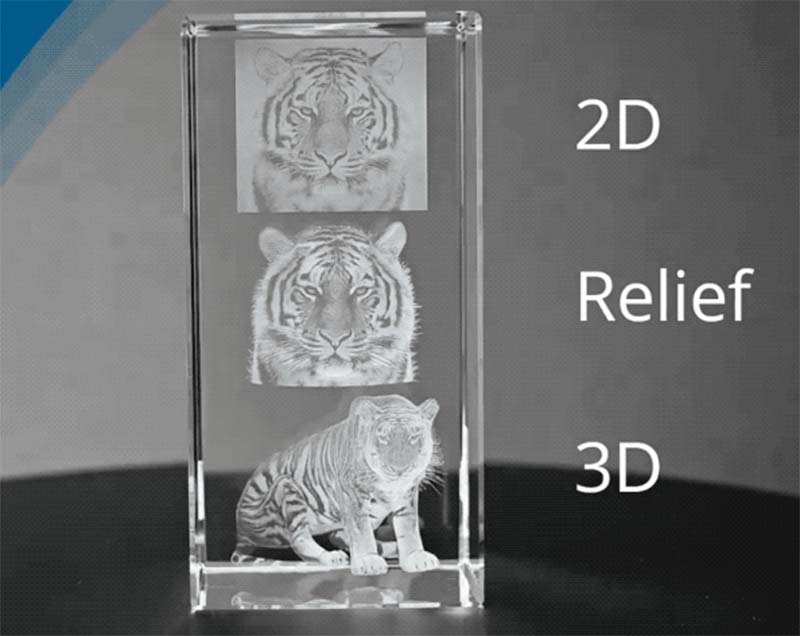

Advanced 3D Laser Marking for Stone Engraving

3D laser marking machines are widely used in high-precision, high-depth applications such as stone engraving. Compared to traditional 2D laser marking, 3D technology overcomes the limitations of flat surface processing by enabling high-accuracy engraving of patterns, text, and QR codes on irregular, curved, or inclined surfaces. This greatly expands the possibilities for both artistic and industrial applications involving natural materials like stone.

Utilizing a high-energy-density laser beam combined with a dynamic focusing system, 3D laser marking achieves real-time focus adjustment within a Z-axis (vertical) range of 0 to 300 mm. The system incorporates a precision servo-driven focusing lens group and a position sensor to form a closed-loop control system, capable of sub-millisecond (<1 ms) response times to ensure the laser remains precisely focused at all times.

For deep engraving or relief carving on complex stone surfaces, the equipment first scans the surface contours using a laser distance sensor. Then, intelligent control algorithms automatically generate a 3D laser path that conforms to the scanned geometry. Whether working on a 30° inclined plane or a naturally uneven rock face, the system dynamically adjusts the focal distance to keep the laser beam perpendicular to the surface, ensuring consistent engraving depth with an accuracy tolerance of ±0.01 mm.

This dynamic focusing capability not only enhances engraving precision but also significantly improves the stability and practicality of laser processing in challenging scenarios such as large-area deep carving and intricate stone reliefs—applications where traditional mechanical engraving methods often fall short.

What Type of Laser Source is best for Stone Engraving?

CO₂ Lasers:

CO₂ lasers generate beams using carbon dioxide gas, typically at a wavelength of around 10.6 μm. This wavelength is highly effective for engraving non-metallic materials and is particularly well-suited for stone. CO₂ lasers are widely used for engraving a variety of stones, including granite, marble, and slate.

Fiber Lasers:

While fiber lasers excel at engraving metals and certain plastics, they are less commonly used for stone. However, they can produce high-contrast markings on some dark-colored stones. Their effectiveness on stone is limited compared to CO₂ lasers.

UV Lasers:

Ultraviolet (UV) lasers feature an extremely fine beam and highly concentrated energy, making them ideal for ultra-precise engraving. They are particularly suitable for delicate materials like jade, crystal, and other stones that require high precision for intricate patterns and micro-text.

Why Use Laser Engraving Machine for Stone?

Traditional stone processing methods such as polishing, sandblasting, and mechanical carving have been widely used for years. However, they come with notable limitations—high labor costs, inconsistent results, and insufficient precision.

In contrast, 3D laser engraving offers significant advantages in terms of precision, speed, stability, and the ability to handle complex curved surfaces. It outperforms traditional mechanical methods across the board. Especially in applications requiring micron-level detail or large-scale, high-consistency production, laser technology delivers unmatched efficiency and quality—making it an indispensable tool in modern stone processing.

| Items | 3D Laser Engraving | Mechanical Engraving |

| Processing accuracy | High precision, with error control at the micron level; ideal for detailed engraving | Precision is limited by the shape of the tool and control accuracy; micron-level processing is difficult to achieve |

| Marking effect | Laser ablation processing, resulting in permanent markings that do not fade and rarely cause cracks | Tool cutting can cause uneven depth or cracks due to material variations |

| Processing speed | Non-contact processing, fast speed, suitable for mass and automated production | Contact cutting results in slow processing speed, especially inefficient on hard stones |

| Consumables and maintenance | No consumables and no contact wear, leading to low maintenance costs | Tools wear out easily, requiring frequent replacement and complex maintenance |

| Processing dimensions | Supports complex 3D surface processing with real-time focus adjustment | Difficult to process complex curved surfaces; often requires custom fixtures or multi-axis equipment |

| Consistency | Long laser system lifespan, stable output, and high consistency in processing | Performance degrades as tools wear, leading to poor processing consistency |

Applications of Small Laser Engraving Machine for Stone

Monument and Tombstone Engraving

Laser marking enables precise engraving of names, dates, and designs on stone surfaces, widely used for personalized monuments and tombstones. The markings are permanent and fade-resistant.

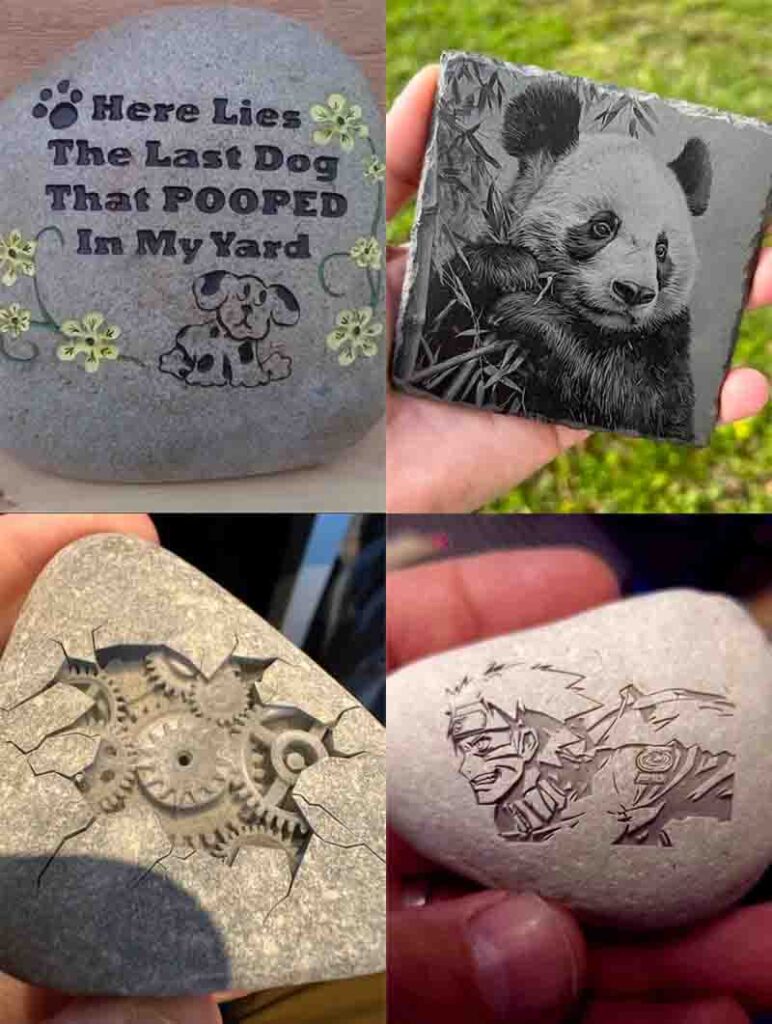

Stone Decorative Artworks

Laser engraving equipment allows the creation of various stone decorative items, such as small statues, stone jewelry, and ornaments, achieving clear details and intricate patterns with high artistic quality.

Custom Souvenirs and Gifts

Fine laser engraving on stone produces personalized gifts and souvenirs, such as commemorative stones or decorative items engraved with names or messages.

Architectural Decoration and Space Art

Laser engraving is ideal for decorating architectural stone surfaces, including walls, columns, and signage, enhancing the design and artistic atmosphere of spaces.

The Best Laser Engraving Machine for Stone

This stone laser engraving machine features advanced 3D dynamic marking technology, combining a high-speed, stable control system with large-aperture galvo optical lenses. It delivers exceptional beam quality across the entire working area, with a minimum line width of just 0.18 mm. With engraving speeds up to 10,000 mm/s, it is well-suited for industrial-scale, high-volume production. The system is built with a fully enclosed optical path, a high-quality imported CO₂ laser source, and multiple layers of protection to ensure long-term stability and performance.

Specifically engineered for hard materials like stone, this high-performance laser machine balances flexibility and professional-grade capability. It supports a wide range of natural and synthetic materials, including granite, marble, pebbles, slate, fiberglass, reinforced glass fiber, and corrosion-resistant plastics (such as PC and PVC).

Features

Pass-Through Design for Materials

The open structure with front and rear material feed allows continuous engraving of oversized stone pieces that exceed the worktable length. Ideal for long-format and complex engraving tasks, it greatly enhances operational flexibility.

Electric Lifting Platform for Variable Thickness

A stable, motorized lift platform enables height adjustment to accommodate materials of different thicknesses. Whether working on thin slabs or thick stone blocks, it supports both surface engraving and deep carving with ease.

High-Precision Laser System

Equipped with a high-power CO₂ laser source, the system delivers crisp, consistent results on hard surfaces. Fine lines, even depth, and sharp edges make it perfect for artistic engraving, tombstone etching, and architectural decoration.

Smart Control System, User-Friendly Operation

Compatible with multiple design file formats and featuring an intuitive software interface, the system supports fast file import, precise positioning, and auto-focusing, significantly boosting efficiency and reducing the learning curve.

How to Laser Engrave Stones?

1. Clean the Stone Surface

Before engraving, thoroughly clean the stone to remove dust, dirt, and any surface residues. A clean surface ensures better engraving quality and prevents interference with the laser beam.

2. Set the Laser Parameters

Laser settings should be adjusted based on the type and hardness of the stone. The key parameters include laser power, engraving speed, frequency, and focal distance.

- Laser Power

Higher power typically results in deeper engraving, but excessive power may cause cracks or surface damage. For stones of medium hardness, use 30W–50W. For harder stones like marble, around 50W is recommended.

- Engraving Speed

Speed refers to how fast the laser head moves during engraving. If the speed is too high, the engraving may be too shallow; too low, and it wastes time. A good starting point for general stones is around 1000 mm/s. For harder stones, reduce the speed to about 600 mm/s. Always run test samples to find the optimal speed.

- Laser Frequency

Frequency determines how many laser pulses are emitted per second. Higher frequency can improve detail but also increases heat buildup, which may affect the surface finish. A typical setting for stone engraving is around 20 kHz.

The following is a reference chart of laser engraving stone parameters

| Power Range | Suitable Stone Types: | Speed | Frequency | Pulse Width | Focal Length |

| Low Power (30-50W) | Softer Stone | 400 – 800mm/s | 15 – 30kHz | 15 – 30ns | 60 – 100mm |

| Medium Power (50-100W) | Medium Hard Stone (Marble, Jade) | 200 – 500mm/s | 20 – 40kHz | 20 – 40ns | 50 – 120mm |

| High Power (100W and above) | Hard Stone (Granite) | 100 – 300mm/s | 30 – 60kHz | 10 – 30ns | 40 – 100mm |

Start Laser Engraving

Once aligned, engraving can begin. The powerful CO₂ laser precisely etches patterns by vaporizing the stone surface, resulting in permanent and detailed engravings. An air filtration system helps reduce the spread of debris and dust, keeping the work area clean.

For example, when engraving a stone measuring approximately 10 cm × 5 cm × 3 cm, the laser power can be set to 25 W, speed to 500 mm/s, frequency to 20 kHz, and focal distance to 180 mm. The engraving process takes about 10 minutes. The actual time will vary depending on the engraving area and the complexity of the design.

Laser Stone Engraving Machine Price

The price of a laser engraving machine for stone can vary widely depending on the machine’s features, laser power, engraving area, and level of automation. Entry-level desktop models suitable for small-scale or hobby use typically start at around $2,000 to $5,000. These machines are ideal for engraving small decorative stones, personalized gifts, and simple artwork.

Before purchasing, it’s important to consider not just the price but also the machine’s compatibility with the types of stone you use, it’s engraving capabilities, and whether it matches your production scale and business goals.

If you’re looking to start a stone engraving business, the initial investment usually includes three main costs: purchasing the laser engraving machine, acquiring stone materials, and covering labor. Compared to traditional manufacturing setups, starting a laser engraving studio is relatively simple, fast, and cost-effective—making it a great entry point for small workshops or custom engraving services.

Summary

In the growing field of stone processing and artistic customization, selecting the best laser engraving machine for stone is crucial to ensuring precision, consistency, and efficiency. From personalized memorials to intricate architectural detailing, a high-performance laser engraver enables clean, high-contrast results on granite, marble, slate, and other natural materials. Whether for industrial or creative use, investing in the right equipment not only boosts productivity but also opens new possibilities in 3D engraving and design.