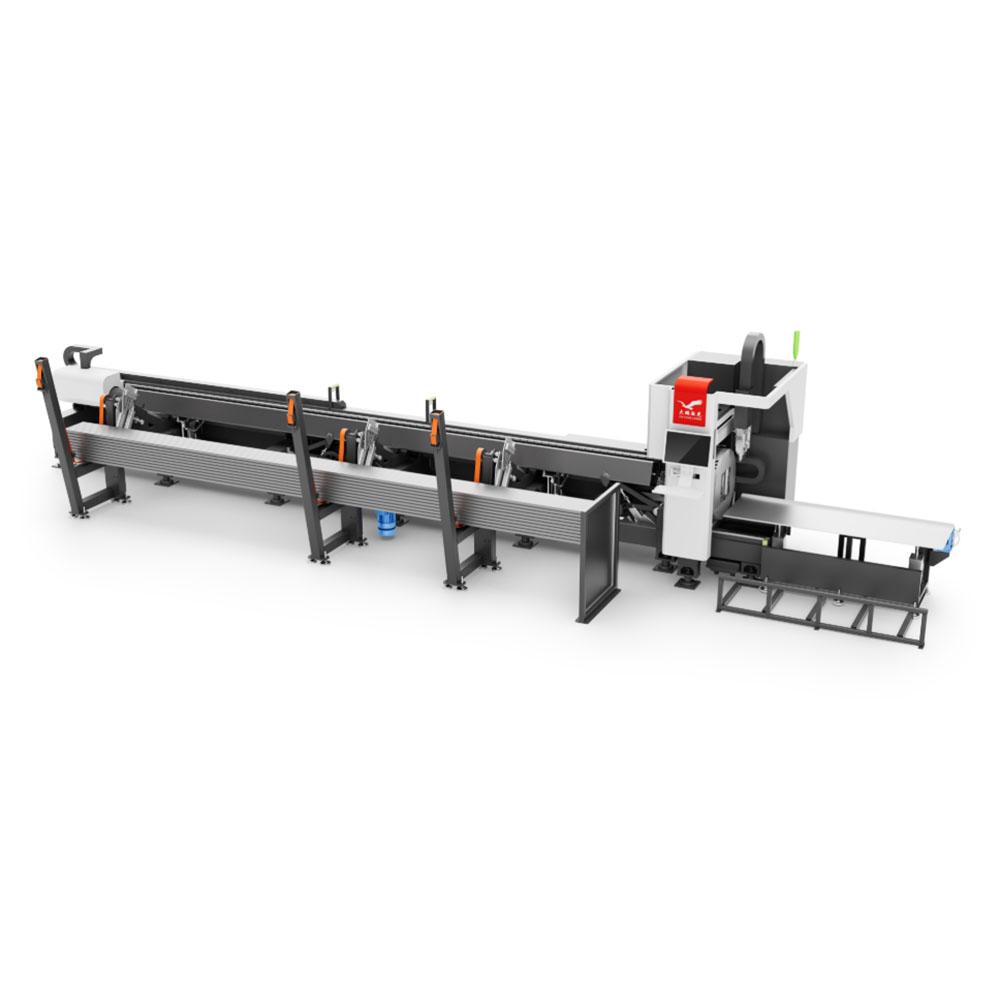

A metal tube laser cutting machine is an advanced tool that uses a focused laser beam to cut, engrave, or drill metal tubes. With the unparalleled energy concentration of the laser, this equipment can achieve extremely high precision in metal cutting, producing clean edges and enabling the creation of intricate patterns. Widely used in industries such as construction, manufacturing, and kitchen equipment production, pipe laser cutting machines are indispensable precision equipment in modern industry. Their exceptional efficiency and accuracy place them at the forefront of metal tube processing.

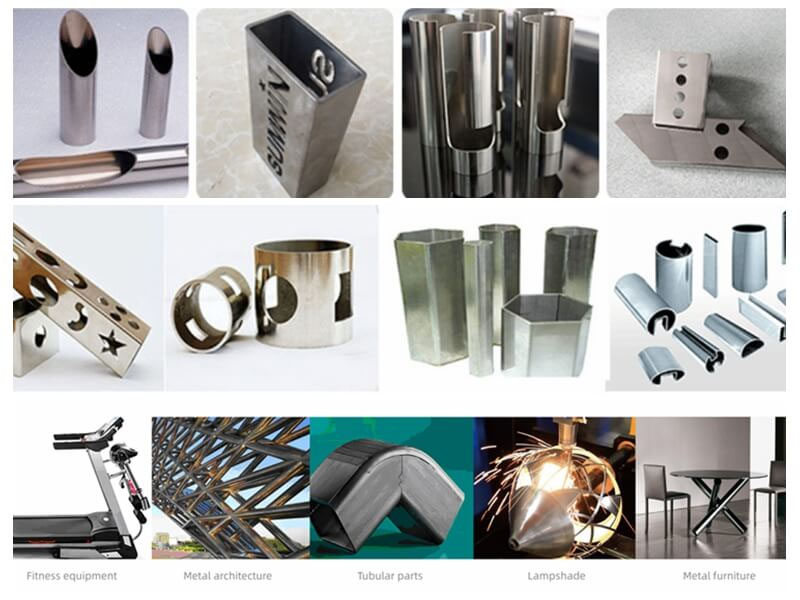

Laser Tube Cutting Machine for Metal Application

Materials Processed

Fiber tube & pipe laser cutting machines are suitable for cutting a wide range of metal materials, especially various metal tubes such as round tubes, rectangular tubes, oval tubes, as well as profiles like channel steel and angle steel. Common materials that can be processed include, but are not limited to, stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, magnesium-aluminum alloy, galvanized sheet, aluminum-zinc coated sheet, pickled sheet, copper, silver, gold, and titanium. Due to the significant differences in hardness, toughness, and thermal conductivity of these materials, the high flexibility and broad adaptability of fiber laser tube cutting machines are particularly important.

Applicable Industries

The application range of fiber laser tube cutting machines is extremely broad, covering almost all industries that require metal sheet and tube cutting.

Metal Sheet Processing: Used for manufacturing various metal products such as machine parts, kitchenware, automotive components, and more.

Advertising Industry: Utilized for making advertising signs and letters, especially those requiring fine cutting and aesthetic appeal.

Electrical Equipment Case: Fiber laser tube cutting machines can precisely cut complex shapes, meeting the high-quality standards of electronic equipment enclosures.

Mechanical Engineering: From large mechanical components to small precision parts, fiber laser tube cutting machines can be used for cutting.

Metal Crafts: Employed in the creation of high-end metal decorations, trophies, and other decorative items.

Saw Blades and Cutting Tools: Fiber laser tube cutting machines can precisely cut sharp edges, suitable for the production of saw blades and various cutting tools.

Electronics Industry: Includes the cutting of circuit boards, microelectronic components, and the manufacturing of precision metal parts.

Hardware Industry: Used in the production of metal fasteners such as screws, nuts, and fittings.

With their high precision, speed, and efficiency, fiber laser cutting machines for tube have become a highly competitive choice in the metal processing field, significantly enhancing industrial production efficiency and product quality.

How to Choose a Tube Laser Cutting Systems?

Metal tube laser cutting machines are highly favored in the manufacturing industry for their precision and efficiency. When selecting this type of equipment, it is crucial to focus on the quality and performance of key components, as they directly impact the cutting results and overall production efficiency. Here are some core parameters to carefully consider when choosing the right laser tube cutting machine:

Fiber Laser Source

Fiber laser source is the heart of laser pipe cutting machine, its performance is directly related to the cutting quality and efficiency. There are various brands available in the market, such as IPG from Germany, Raycus from China and SPI from UK. These high-end laser sources are known for their excellent cutting speed and stability, as well as their long service life and low maintenance costs.

Control System

The control system of the laser tube cutting machine is the brain of the laser tube cutting machine, which is responsible for coordinating the operation of various components to ensure the stability and reliability of the machine. It enables the laser beam to move accurately in accordance with the preset path by precisely controlling the movement of the X, Y, and Z axes, and regulates the power output of the laser to achieve high-precision cutting operations.

Cutting Head Assembly

The laser cutting head is the output end of the laser energy and consists of a nozzle, a focusing lens and a focus tracking system. During processing, the cutting head must follow a set path, but when dealing with different materials, thicknesses, or different cutting strategies, it must be able to flexibly adjust to control the distance between the laser cutting head and the workpiece to ensure optimal cutting results.

Servo Motor

A servo motor is an engine that controls the operation of mechanical components in a servo system. Servo motors enable control of speed, positional accuracy is very accurate, and can convert voltage signals into torque and speed to drive the control object. High-quality servo motor can effectively ensure the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutting machine.

Bed Frame

In addition to considering load capacity, the structure design of the machine bed in a tube laser cutting system is critical because it directly affects load-bearing capacity and tube cutting precision.

A twisted or deformed bed frame severely impacts the machine’s accuracy and lifespan. Dapeng Laser uses materials with good tensile strength and rigidity, such as cast iron and special alloy steel, to manufacture the bed frames of its laser cutting machines. Emphasizing overall structural design ensures high rigidity and stability, enabling the bed frame to withstand the stress challenges posed by high loads and continuous cutting while maintaining long-term accuracy. Precision welding technology is used to ensure the strength and consistency of the weld seams, and annealing processes are employed to eliminate internal stresses generated during welding, preventing deformation of the bed frame over time.

Tail Material Control Requirements

Laser tube cutting machines can be classified by the number of chucks into single-chuck, double-chuck, triple-chuck, and quadruple-chuck types. When dealing with heavy-duty tubes, using a triple-chuck or quadruple-chuck cutting solution is preferable to ensure high precision and efficiency. Zero tail material and extremely short tail material are ideal outcomes pursued by the processing industry. Currently, only triple-chuck or quadruple-chuck cutting machines can achieve zero tail material cutting. Tail materials shorter than 80 mm are considered extremely short tail materials, which can typically be achieved with double-chuck laser tube cutting machines.

Processed Tube Parameters

The processing capability of a fiber laser tube cutter is primarily assessed based on tube diameter, wall thickness, and workpiece length.

Tube Diameter: The tube diameter refers to the outer diameter of the tube being processed. The chuck design of the laser cutting machine for tube determines the maximum diameter it can accommodate. Check the equipment specifications for chuck size information to ensure it meets the diameter requirements of your tubes. For handling various tube specifications, choose a machine that can accommodate the maximum diameter required. Pneumatic chucks are currently the most popular due to their simple structure, low failure rate, and high precision.

Tube Wall Thickness: Wall thickness is the measure of the tube’s thickness and directly affects the cutting capability and efficiency of the pipe laser cutting machine. Factors such as laser power, focusing lenses, and auxiliary gases and their flow rates will influence the cutting performance on different wall thicknesses.

Workpiece Length: Workpiece length refers to the effective length of the tube that can be processed in a single operation, affecting the continuity of processing and production efficiency. The length of the tube & pipe laser cutting machine’s bed and the configuration of its automated feed system determine the maximum tube size it can handle. Confirm the maximum workpiece length required for your production and compare it with the machine’s bed length to ensure that the equipment can cover your processing needs.

DPLASER Automatic Laser Tube Cutting Machines can handle metal tubes with diameters from Ф20~Ф400mm and lengths up to 6500mm. For other size requirements, we offer customization options to meet your production needs. Please feel free to contact us.

Accessories such as chucks, rails, racks, lead screws, motors, cables, and air circuits play a crucial role in the machine’s performance. High-quality accessory systems can enhance the processing capability of the fiber laser cutting machine.

Accessories

Pipe laser cutting can be done at various angles, including but not limited to the common 30°, 45°, 90° and other angles, and can also be done at any angle as needed. This is due to the high flexibility of the laser cutting machine and the advanced control system, they can precisely adjust the position and angle of the cutting head to meet the cutting needs of different shapes and angles.

CNC laser tubes cutting machine is suitable for: metal square tube, round tube, rectangular tube, triangular tube, oval tube, waist-shaped tube, D-shaped tube, hexagonal tube and other shaped tube cutting, support tube truncation, cut holes, beveling, hollowing, cutting shapes and other angles, arcs, curves, irregular shapes cutting processing. When cutting bevels or special shapes, some additional accessories or functions may be required to realize more complex cutting needs.

For example:

Rotary Head: A rotary head allows the tube to rotate during cutting, which is particularly important for bevel cutting as it enables the laser beam to contact the tube surface from different angles to form the desired bevel.

Tilting Cutting Function: Some high-end laser tube cutting machines are equipped with a tilting cutting function that allows the laser head to adjust its angle directly to cut bevels on the tube without the need for additional mechanical devices.

Multi-Axis Control: To cut complex three-dimensional shapes, laser tube cutting machines are often equipped with five-axis or six-axis control systems, enabling movement in the X, Y, Z directions as well as rotation around the A and B axes, making the cutting path more flexible and diverse.

The most reliable method of evaluation is to conduct an actual sample cutting test (proof test). Through this process, you can not only observe the actual performance of the pipe cutter, but also verify its processing accuracy and efficiency under specific conditions. If you have pipe cutting needs, please feel free to contact us to help you with free proofing.

Selecting the best metal tube laser cutting machine is a key step in ensuring production efficiency and quality. This article explores the cutting capabilities, application, and selection parameters of CNC pipe & tube laser cutters in detail, helping you choose the best laser cutter for pipes. If you need further consultation or have any questions, please do not hesitate to contact us. We are dedicated to providing support and customized laser tube cutting solutions to meet your specific requirements.