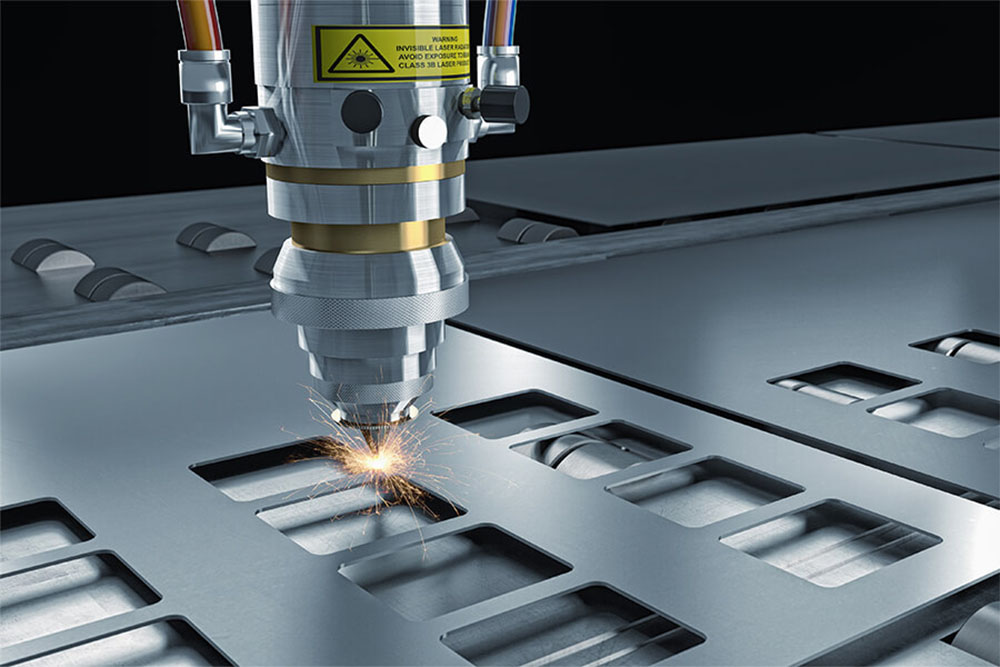

Laser Cutting Aluminum

Benefits of Laser Cutting Aluminum Sheet

Laser cutting is the ideal method for cutting aluminum in manufacturing. Its primary advantage lies in precision, as laser beams can create small holes, sharp cuts, and high-quality edges with an accuracy of ± 0.0005 inches. This makes laser cutting suitable for various applications, including cans, foils, electronic parts, electrical boxes, cabinets and window frames.

- Reflectivity and Absorption:

Aluminum has high reflectivity for traditional cutting methods like plasma or oxy-fuel cutting. Laser cutting is effective with aluminum alloy due to its high absorption of laser energy, making it well-suited for the process. - Precision in Thin Materials:

Laser cutting is exceptionally precise, making it ideal for thin aluminum sheets. The focused laser beam ensures accuracy and sharpness in cutting even fine details. - Reduced Heat Affected Zone (HAZ):

Aluminum is sensitive to heat, and laser cutting minimizes the heat affected zone. This is crucial for maintaining the structural integrity of the material and preventing undesirable changes in properties. - Versatility in Thickness:

Laser cutting machines can handle a broad range of aluminum thicknesses, providing flexibility for various applications.

- No Physical Contact:

Laser cutting is a non-contact process, meaning there is no tool-to-material interaction. This reduces the risk of contamination or damage to the aluminum surface, resulting in clean and precise cuts. - Intricate Designs and Fine Details:

The precision of laser cutting allows for the creation of intricate designs and the cutting of fine details. This is particularly beneficial in industries where intricate patterns or complex geometries are essential. - Minimal Material Waste:

Laser cutting minimizes material waste since it is a precise, computer-controlled process. - Fast Setup and Changeover:

Laser cutting machines have quick setup times and do not require extensive tool changes, reducing downtime between different cutting jobs.

Why Choose DP LASER Aluminium Laser Cutting Machine?

- By choosing components with different parameters and brands, we can customize them to your production needs in order to optimize the configuration of your laser cutting machine for superior cutting results.

- DPLASER aluminum laser cutter range in power from a few hundred watts to tens of thousands of watts. 3,000W laser cutting machines are suitable for aluminum materials as small as 8 mm, while 6,000W laser cutter can easily cope with aluminum alloys as thick as 16 mm, guaranteeing smooth cutting edges while no burrs.

- Our fiber laser cutter not only accurately cut plates and tubes, but also support a wide range of materials, which are particularly suitable for metal aluminum plates and aluminum alloy tubes, including shaped tubes.

- Compared to traditional metal cutting processes, our fiber laser cutting systems offer outstanding productivity with a tenfold increase in efficiency, bringing greater convenience and benefits to your production.

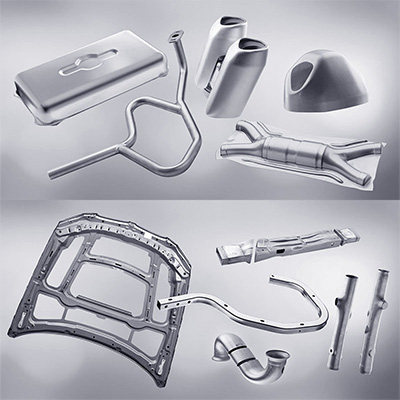

Industrial Applications: Laser Cutting for Aluminum

Kitchens & Utensils

Laser cut aluminum is vital in kitchenware and various industries for its precision, minimal material damage, and efficiency. It enables intricate designs, maintains material integrity, and boosts production speed, allowing for adaptability to market demands.

Machinery Manufacturing

Aluminum laser cutter designed for machinery manufacturing, facilitating bulk production of precision components.

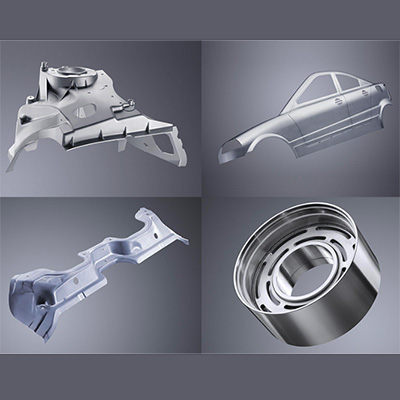

Automotive Industries

Laser cutting metal and aluminum for motorcycle manufacturing ensures precise fabrication of high-precision components.

Aerospace

Aluminum laser cutting for aerospace is vital for producing lightweight yet strong components essential. This technology ensures precision, minimal material waste, and the ability to create intricate designs, meeting the high-performance and efficient manufacturing.

Electronics

Laser cutting aluminium sheet for electronics is essential, particularly for components like heat sinks, PCB, chassis and housings that demand precise dimensions.

Get a Free Laser Cutting Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.