The forms of advertising signs and letters have become more diverse. Among them, metal advertising letters are gaining widespread application, and the number of manufacturers using laser welding machines continues to grow. Signboards are usually made of metal materials and often require assembly into wide structures, where smooth and aesthetically pleasing seams are essential. A laser welding machine for advertising word not only meets the demanding requirements of metal welding but also minimizes material deformation caused by high temperatures, ensuring the superior appearance and quality of advertising signs.

Advertising signboards commonly use arc welding machines, where connections are made through lap joints by spot welding or seam welding. This not only increases the weight but also tends to create angles that weaken tensile and fatigue strength at the joints, raising the risk of detachment. At the same time, arc welding machines consume large amounts of energy and are difficult to operate, requiring skilled workers, which further drives up the production cost of advertising signs.

Advantages of Laser Welding for Advertising

As a new generation of continuous fiber welding equipment, laser welding machines can fully replace traditional resistance welding and pulse welding. They deliver fast welding speed, minimal thermal deformation, and highly precise metal joining. The resulting welds are smooth and visually appealing, eliminating the need for post-grinding or finishing. With its high efficiency, laser welding greatly improves the production speed of advertising letters. Compact in size and equipped with a handheld welding gun, the machine is simple to operate—complete beginners can master it within half a day.

High Welding Speed

Laser welding offers extremely rapid heating and cooling, making the process faster and more efficient.

Superior Weld Quality

It enables precise seam alignment and produces strong, reliable, and aesthetically pleasing welds, enhancing the overall appearance of advertising signs.

Minimal Heat-Affected Zone

With low heat input and a narrow heat-affected zone, laser welding effectively prevents material deformation and performance degradation.

Wide Material Compatibility

It can process a variety of metals and non-metals, including materials with high hardness, brittleness, or melting points.

Low Environmental Requirements

A handheld laser welding machine requires no dedicated workbench. Compact and flexible, it can be equipped with several meters of optical fiber extension for long-distance, mobile operation without being limited by workspace conditions.

Continuous Operation

Equipped with water-cooling systems, the laser source supports sustained high-intensity operation for industrial-scale production.

Different Between Laser Welding and Traditional TIG Welding

Compared with conventional TIG (argon arc) welding, fiber laser welding machines offer significant advantages:

Energy Consumption

A handheld laser welding machine can save approximately 80–90% of electricity compared to traditional arc welding, reducing overall processing costs by about 30%.

Welding Performance

Laser welding enables the joining of dissimilar steels and metals with high speed, minimal deformation, and a very small heat-affected zone. The welds are smooth and aesthetically pleasing, with no pores and minimal contamination. Laser welders can also handle micro-groove components and precision welding applications.

Post-Processing

With low heat input and reduced workpiece distortion, laser welding produces clean, attractive seams that require little to no finishing. This significantly reduces the need for labor-intensive polishing and leveling processes, thereby cutting down on manual costs.

Advertising Laser Welding Machine for Metal Letters

Commonly used materials for metal billboards include stainless steel, brass, tinplate, galvanized sheet, and cold-rolled steel. Traditional TIG welding often leaves burn marks on the backside when working with thin metal sheets. Using thicker sheets may avoid this issue, but they are costly, heavy, and difficult to install.

For this reason, sign manufacturers typically prefer metal sheets with a thickness between 0.3 mm and 1 mm, which are more economical and practical.

Applications of Laser Welding for Advertising Word

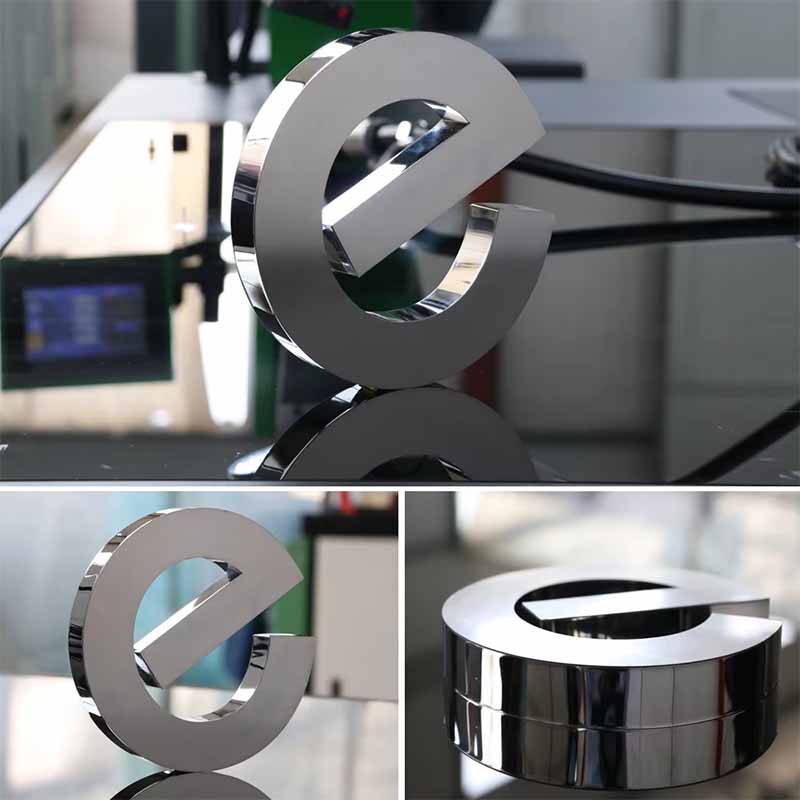

Laser welding machines for advertising applications are designed for thin-walled materials and precision parts. They provide high depth-to-width ratios, narrow weld seams, minimal heat-affected zones, and low distortion—all at high welding speeds. These advantages make them ideal for metal advertising letters, signboards, stainless steel characters, illuminated LED letters, logos, nameplates, light boxes, and metal frames, ensuring fast and precise welding results.

Stainless Steel Illuminated Letters

For storefront signs and shopping mall displays, laser welding joins panels and borders seamlessly. The welds are smooth, burr-free, and require no secondary grinding. With no deformation after welding, the letters maintain uniform illumination.

Aluminum Alloy Letters in Mass Production

When paired with automatic feeding systems, laser welding enables fully automated production lines with loading, welding, and unloading functions. Daily output can reach 500–1000 letters, greatly enhancing production efficiency.

Mini LED Letters

For miniature illuminated letters, the metal base and acrylic faceplate are joined with pulse laser spot welding. With weld spots smaller than 0.3 mm, hidden within seams, the joints are strong yet do not affect light transmission.

Custom Shapes and Complex Designs

Laser welding easily handles irregular letter shapes such as logos and artistic fonts. It can weld along curves and arcs, and by importing designs through CAD software, the machine automatically generates welding paths to achieve personalized customization.

Laser Advertising Welding Machine

In the advertising production industry, a reliable laser welding machine for advertising letters can significantly enhance production quality and efficiency, solve many challenges associated with traditional welding methods, and become a valuable tool for your advertising manufacturing business.

Product Advantages

Industry-Specific Design – Specially designed for the advertising letter manufacturing industry, featuring self-developed waveform optimization technology with adjustable weld depth, controllable spot size, and high welding strength.

Precision Control System – Equipped with a proprietary precision power supply, high anti-interference circuitry, and a touchscreen interface that is intuitive and easy to operate.

Superior Weld Performance – Produces welds that resist detachment, have minimal heat-affected zones, maintain shape, and leave no marks on the backside. Adjustable welding energy allows both thick and thin metal plates to be welded efficiently, reducing material costs.

Smooth Weld Surface – Welded surfaces are smooth and require no polishing, saving time and labor.

Extended Optical Path – Specifically designed for the advertising industry with a longer optical path, providing greater flexibility.

High Efficiency – Comes with a dedicated positioning device suitable for welding various irregular letter shapes and patterns.

Long Focal Lens – Custom F=200 mm long-focus lens meets the requirements for welding extra-large characters.

Optional High-Definition CCD Monitoring – With an LCD display and positioning system, the welding spot can be quickly located, simplifying operation, increasing efficiency, and reducing operator fatigue. It effectively replaces traditional soldering and TIG welding for signage.

Optional Automated Welding System – Ensures uniform and adjustable weld points, suitable for letters of different sizes and fonts, further improving production efficiency.

Exceptional Weld Quality

Traditional welding often leaves burn marks on the backside of thin metal sheets, causing distortion and affecting aesthetics. In contrast, the laser welding machine minimizes the heat-affected zone and precisely controls energy input, avoiding deformation and discoloration. Whether working with stainless steel or brass, it produces uniform, strong, and smooth welds without depressions, enhancing the quality and visual appeal of advertising letters.

High-Efficiency Welding

Laser welding operates at several times the speed of traditional methods. For example, advertising letters ranging from 3 cm to 160 cm can be welded quickly, greatly shortening production cycles. From small storefront signs to large outdoor advertising letters, it handles every task efficiently, allowing businesses to take on more orders and improve overall profitability.

Wide Applicability

The laser welding advertising machine is compatible with various advertising letter metals, including stainless steel, galvanized sheet, cold-rolled steel, and tinplate, with welding thickness ranging from 0.2 mm to 1.0 mm. It meets the needs of different advertising materials and finds applications in advertising letter production, metal processing, and electronic device manufacturing. The laser welding machine can weld different materials such as stainless steel, aluminum alloy, and copper, ensuring high-quality and visually appealing results.

How to Use a Laser Welding Machine for Advertising Letters

1. Preparation Stage

Before starting the welding process, ensure that the workpiece surface is clean, free of oil, and free of debris, as this greatly improves welding quality. Next, set the welding parameters according to the material, thickness, and welding requirements of the workpiece. Key parameters include laser power, welding speed, and pulse width, which can typically be adjusted directly via the machine’s control panel.

2. Fixing the Workpiece

Place the workpiece securely on the welding table and use clamps or fixtures to hold it in place. Modern laser welding machines are often equipped with high-precision fixtures, which maintain stable positioning during welding and effectively reduce welding errors.

3. Executing the Welding

Once everything is ready, start the machine. The laser will work according to the preset parameters, focusing precisely on the welding spot. The high-intensity laser rapidly melts and fuses the material. During the welding process, the operator can monitor the progress in real-time through the machine’s monitoring system, ensuring that weld quality meets standards.

In summary, laser welding for advertising word production offers a revolutionary upgrade over traditional welding methods. It not only enhances the welds quality of signs, logos, and illuminated letters but also significantly improves production efficiency, reduces material waste, and lowers labor costs. Whether for small storefront signs, large outdoor letters, or custom-shaped logos, laser welding provides a reliable, high-quality solution that empowers advertising manufacturers to deliver superior products, meet diverse design requirements, and stay competitive in a fast-paced market.