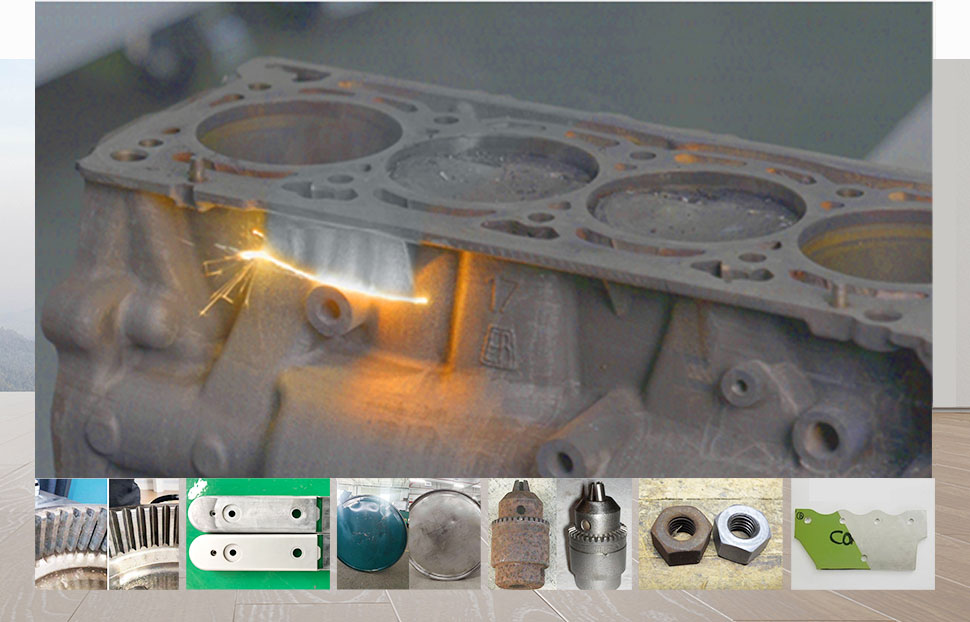

In 2025, the demand for cost-effective and efficient cleaning solutions is driving the popularity of the cheap laser cleaning machine for metal on the market. From lightweight backpack laser cleaners to 3 in 1 handheld laser cleaning machines, these advanced devices offer a fast, eco-friendly, and non-abrasive way to remove rust, paint, grease, and surface contaminants from metal, stone, and other materials. By combining affordability with professional-grade performance, budget-friendly laser cleaning machines are becoming a smart choice for workshops, maintenance teams, and small manufacturers looking to improve cleaning efficiency.

Why Choose a Backpack Handheld Laser Cleaning Machine?

As affordable laser cleaning machine occupy the laser cleaning market gradually, it is becoming the new favorite for metal surface treatment. With advantages such as portability, efficiency, and eco-friendliness, small handheld laser cleaning machines offer an ideal solution for cleaning tasks in complex environments.

In metal processing and manufacturing, many large-scale machines or components installed in special locations cannot be cleaned with traditional equipment. A backpack handheld laser cleaning machine is lightweight and portable, allowing it to be brought directly to the target area—whether it’s a section of massive machinery or a hard-to-reach gap or corner, it can deliver precise and efficient cleaning. Its ergonomic design makes operation more flexible while ensuring uniform and consistent cleaning results. This portability not only significantly improves work efficiency but also reduces the time and costs associated with moving equipment.

The backpack-style design makes the cleaning machine even lighter and easier to carry, making it suitable for various complex environments and job sites, thus enhancing both flexibility and convenience in cleaning operations.

Advantages of Portable Laser Cleaning Machine

High-Efficiency Cleaning

With highly concentrated laser energy, surface contaminants can be completely removed in an extremely short time. The cleaning speed far exceeds that of traditional methods. For large-scale hardware processing enterprises, it can significantly shorten process time, improve production efficiency, and quickly respond to market demands.

Precise Control

Equipped with an advanced laser cleaning system, the machine allows precise adjustment of laser parameters according to different substrate materials and types of contaminants. It is suitable for various scenarios such as complex molds and precision components, ensuring stable and consistent cleaning results.

Versatile Operation

The handheld laser cleaning gun enhances convenience in cleaning tasks. By manual operation, it can clean irregular surfaces of workpieces, especially corners, convex and concave surfaces, and other non-standard shapes. For thicker contaminants, the same area can be cleaned multiple times.

Eco-Friendly and Pollution-Free

The cleaning process requires no chemical agents and produces no wastewater or waste residue—zero emissions, in line with the concept of green production. This helps enterprises improve their social image and competitiveness.

Non-Damaging Operation

Using non-contact cleaning, no mechanical stress is applied to the workpiece surface, avoiding damage. It is particularly suitable for high-precision, high-value parts such as precision molds and aerospace or automotive components.

Supports Remote Control

The laser beam can be transmitted over long distances through optical fiber, easily integrating with robotic arms and automation systems for automated cleaning. This is especially useful for high-demand scenarios such as hazardous areas, complex structures, and curved surfaces.

Industrial Applications of Laser Cleaning Machines

Mold Manufacturing

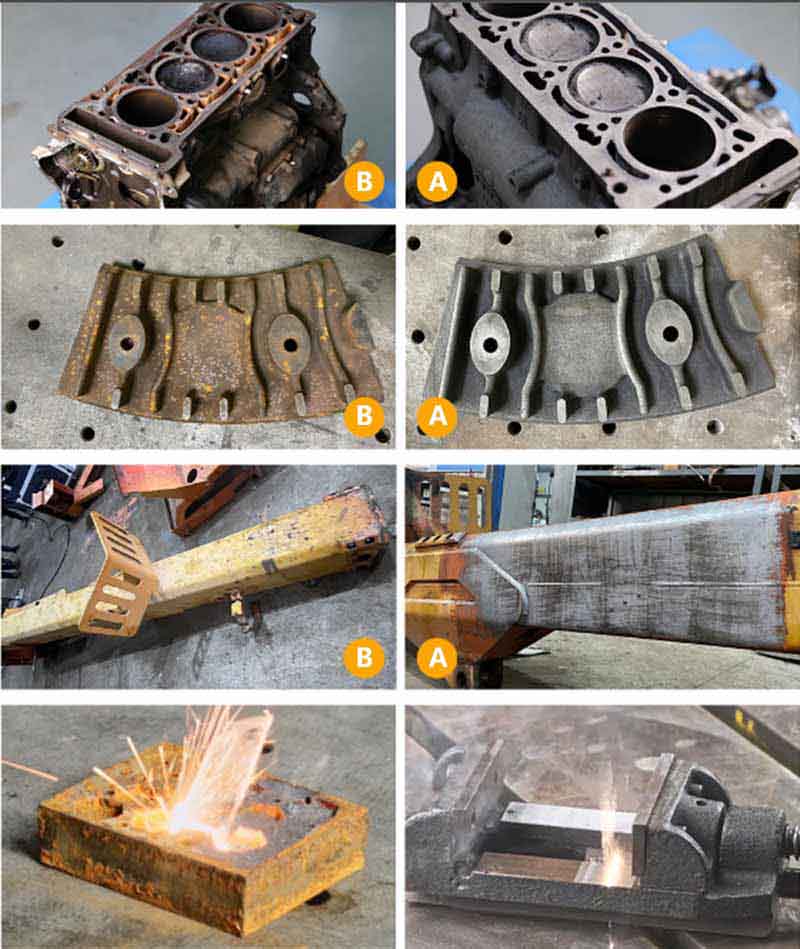

During mold production, surfaces often accumulate contaminants, oxidation layers, and residues that can affect mold precision and shorten service life. Laser cleaning efficiently removes these impurities, restores mold accuracy, and significantly extends its operational lifespan.

Hardware Processing

The surface quality of hardware products directly determines their appearance and performance. Laser cleaning technology quickly removes grease, rust, and old coatings, leaving surfaces clean and smooth, enhancing both the aesthetics and added value of the finished product.

Automotive Parts Manufacturing

Automotive components require extremely high standards of cleanliness and precision. Laser cleaning machines precisely remove dirt and residues from part surfaces, improving machining accuracy and surface quality to ensure stable performance.

Application Scope

Laser cleaning is suitable for removing paint layers, rust, oxidation, coatings, grease, and other surface contaminants. It is also ideal for pre-treatment in automotive parts production, 3C electronics manufacturing, precision mold refurbishment, and lithium battery electrode cleaning. Additionally, it supports welding surface preparation before welding, as well as oxide layer removal after welding.

The Best Budget Laser Cleaning Machine 2025

Compact Backpack Laser Cleaning Machine

With its lightweight, compact, and highly portable design, the backpack handheld laser cleaning machine has become a popular choice in the laser cleaning field. Using pulsed laser beams, it offers multiple advantages including high efficiency, fast cleaning speed, zero pollution, non-contact operation, and damage-free performance. It is widely used across aerospace, automotive manufacturing, electronics, and many other industrial sectors.

Product Advantages:

Non-Contact Cleaning — Protects the Workpiece Surface

Removes contaminants from delicate components without causing any mechanical damage.

Precision Cleaning

Delivers accurate surface cleaning without harming the base material, ensuring superior cleaning results.

Portable Design — Easy Mobility

Backpack-style form allows easy carrying and mobility, perfect for on-site cleaning in complex environments.

Simple Operation — Easy to Learn

Streamlined operation lowers the skill barrier and improves work efficiency.

No Consumable Costs — High Efficiency

Eliminates the need for traditional cleaning materials, reducing costs while boosting cleaning speed and extending equipment lifespan.

Targeted Cleaning — Selective Removal

Enables precise, spot-specific cleaning for different materials and contaminations without damaging the substrate.

Buying Tips

Before purchasing a portable laser cleaning machine, it is essential to clearly define your application scenarios and cleaning requirements. Consider the material of the workpiece, type and level of contamination, cleaning area size, and precision requirements to ensure the equipment meets your operational needs.

Choose reputable brands such as Dapeng Laser, whose extensive technical expertise and strict quality control ensure stable performance and reliability. Equally important is comprehensive after-sales service, including installation, commissioning, operation training, maintenance, and technical support, to help users resolve issues promptly, extend equipment lifespan, and improve productivity.

1500W/2000W/3000W Handheld Laser Cleaning Solutions

Stable & Efficient Laser Control System

Equipped with industrial-grade laser and optical control technology, the system delivers highly stable laser power output with minimal fluctuation, ensuring efficient and consistent cleaning or welding performance.

Portable Handheld Design

Lightweight and easy to operate, the handheld laser cleaning system adapts to diverse working scenarios and meets real-world user needs.

Dual-Temperature, Dual-Control Water Cooling

A professional water-cooling design ensures long-term stable operation and improved working efficiency.

Non-Contact & Eco-Friendly Cleaning

The specialized cleaning head enables non-contact cleaning that protects the base material from damage. No consumables, no pollution — a green and efficient solution.

High-Performance Cleaning

With an 800 mm focal length design, operators can work comfortably, achieving a cleaning width of up to 300 mm. Floating rust removal rates reach up to 20 m²/hour, and even beginners can quickly master the operation.

No Dead Corners

Adapts to complex workpiece geometries, achieving 0° curvature full-coverage cleaning to meet varied cleaning requirements.

Multiple Safety Protections

Features dual safety controls — safety lock plus trigger — to ensure operator safety.

User-Friendly Design

Compact and portable, equipped with a larger protective lens that’s easy to remove and replace, offering excellent protection for various industrial environments.

Trolley Design

Comes with a retractable handle and caster wheels for easy single-person mobility.

Applications

This handheld laser cleaning system is ideal for rust, paint, and grease removal, designed specifically for cleaning coatings and deposits from metal surfaces. It provides comprehensive cleaning solutions for shipbuilding, vehicles, rail transport, and machinery manufacturing & maintenance. It also excels at cleaning molds, cookware, precision parts, and grease or stubborn contaminants from small or confined metal surfaces.

How to Choose the Best Budget Laser Cleaning Machine 2025

1. Identify the Material and Characteristics of the Workpiece

Different materials respond differently to laser wavelength and energy. For example, metal oxides typically require high-power pulsed lasers, while paint or coating layers are better suited to short-wavelength continuous lasers. Choosing a model with adjustable parameters ensures effective cleaning without damaging the base material.

2. Balance Power and Cleaning Precision

High-power laser sources are ideal for quickly removing large-area contaminants but may compromise detail-level cleaning. Low-power devices are better suited for precision instruments or cultural relic restoration, offering greater accuracy at the cost of speed.

3. Consider Automation Level

Automation can significantly improve efficiency. For batch production environments, intelligent cleaning systems integrated with robotic arms or conveyor belts are recommended. In laboratories or small workshops, portability and operational flexibility are often more important.

4. Evaluate After-Sales Service and Costs

The lifespan of the laser, the replacement cycle of optical lenses, and the supplier’s technical support directly affect the long-term usability of the equipment. Comprehensive after-sales service ensures consistent performance and minimizes downtime.

Factors Affecting the Price of a Laser Cleaning Machine

Laser Source

Laser sources with more advanced technology and precise control functions are usually more expensive. Different types of lasers, such as pulsed lasers and continuous lasers, also have significant price differences.

Configuration and Features

Additional features such as automatic scanning systems, cooling systems, intelligent control systems, and user interfaces can increase the cost. Higher cleaning precision and the ability to handle different materials or complex workpieces also raise the price.

Brand Influence

Well-known brands often charge more due to their reputation for quality and reliability compared to lesser-known brands.

Machine Size and Power

Large industrial machines designed for bigger and more complex cleaning tasks are more expensive than handheld or portable models.

Machine Type

- Handheld laser cleaning machines are less expensive and suitable for small-scale or mobile cleaning tasks.

- Industrial machines are more costly and ideal for high-volume, fast cleaning tasks.

- Portable machines fall in between, balancing price and performance.

Laser Cleaning Machine Price

Continuous Handheld Laser Cleaning Machines

3-in-1 1500W laser cleaning machine: approximately $3,500

Laser cleaning machines with 1500W to 3000W power: $3,500–$6,000

Pulsed Handheld Laser Cleaning Machines

Power range 100–500W: approximately $3,000–$8,000

High-power handheld laser cleaners: typically above $8,000

Actual prices may vary depending on brand, configuration, and after-sales service. It is recommended to choose the model that best suits your specific needs.

How to Use a Handheld Laser Rust Removal & Cleaning Machine

- Power On and Self-Check: Turn on the machine and wait for it to complete the self-check before entering operational mode.

- Set Parameters: Adjust power, scanning speed, focus, and other settings according to your specific needs to ensure optimal cleaning results.

- Align and Clean: Maintain the appropriate distance, aim the laser beam at the rusted area, operate steadily, and use a back-and-forth scanning motion to cover the surface.

- Monitor the Process: Keep an eye on the machine’s operating status and the cleaning effect to avoid energy waste.

The Top Laser Cleaning Machine Brands in 2025

MaxWave Laser (China)

MaxWave Laser is a Chinese company that is also well-known in the Canadian market. They offer a range of laser cleaning equipment, including portable and high-power industrial systems, suitable for rust removal, coating removal, and surface preparation applications. For example, the MaxWave LY handheld laser cleaning machine is available in 1000W, 1500W, and 2000W options, featuring a compact design and user-friendly operation, ideal for various industrial sites.

STYLECNC (China)

STYLECNC offers handheld fiber laser cleaning machines with power ranging from 1500W to 3000W, suitable for removing rust, oil stains, and coatings from metal, wood, and stone surfaces. These machines are cost-effective, durable, and consumable-free, meeting the needs of applications from home use to industrial tasks.

Han’s Laser (China)

Han’s Laser, one of China’s leading laser equipment manufacturers, was founded in 1996 and is headquartered in Shenzhen. They provide a variety of laser cleaning solutions, including handheld and fixed systems, widely used in automotive, shipbuilding, steel, and other industries.

Laser Photonics (USA)

Laser Photonics is a U.S.-based laser technology company specializing in the design and manufacture of laser cleaning and laser stripping systems. They offer handheld and fixed laser cleaning systems widely used in industrial maintenance, manufacturing, and repair. Laser Photonics products are known for their efficiency, environmental friendliness, and customizable solutions.

Founded in China, DAPENG Laser is a high-tech enterprise specializing in the research, development, manufacturing, and sales of laser equipment. The company focuses on innovation and production of laser cleaning machines, laser marking machines, and laser cutting equipment. With advanced optical technology and independent R&D capabilities, DAPENG Laser has become one of the most influential brands in the industry.

DAPENG Laser emphasizes customized solutions for clients, offering laser cleaning machines in various power levels and specifications to meet diverse cleaning tasks, from light industry to heavy industry. DP Laser provides high-quality laser cleaning products with prompt after-sales service. With a professional R&D team and advanced production equipment, we can customize solutions according to customer requirements. Our comprehensive logistics system and after-sales network ensure timely delivery and reliable quality.