Food packaging plays a vital role in maintaining product quality and safety. Packaging materials must be carefully selected to comply with industry standards and both national and international regulations. Many businesses are now seeking cost-effective and environmentally friendly marking solutions that do not compromise food safety. This is why UV laser marking machine is gaining widespread adoption. A UV laser marking machine for packaging enables precise branding, traceability, and product information marking, identification, authentication, and tracking.

UV laser marking, also known as cold light source marking, involves using a laser beam to create permanent marks on the surface of various materials. UV laser marking uses short-wavelength lasers to directly break the molecular bonds of the material, thereby revealing the desired pattern, text, or design.

UV laser marking machines utilize a unique 355nm ultraviolet laser that can be focused into an extremely small spot. This feature significantly reduces the risk of material deformation and minimizes the thermal impact during processing. As a result, UV laser marking machines excel in ultra-fine marking and engraving. They are especially suitable for marking and micro-perforating the surfaces of cosmetic, pharmaceutical, and food packaging bottles made from polymer materials, as well as for high-speed scribing of glass and complex pattern cutting of silicon wafers.

Compared to green and infrared lasers, uv lasers produce significantly less thermal effect. As the wavelength decreases, the absorption rate of various materials increases, even allowing for direct alteration of molecular chain structures. In the field of micro and nano level ultra-precision processing, especially for heat-sensitive materials, UV lasers demonstrate distinct advantages.

Is UV Laser Marking Safe for Food Packaging?

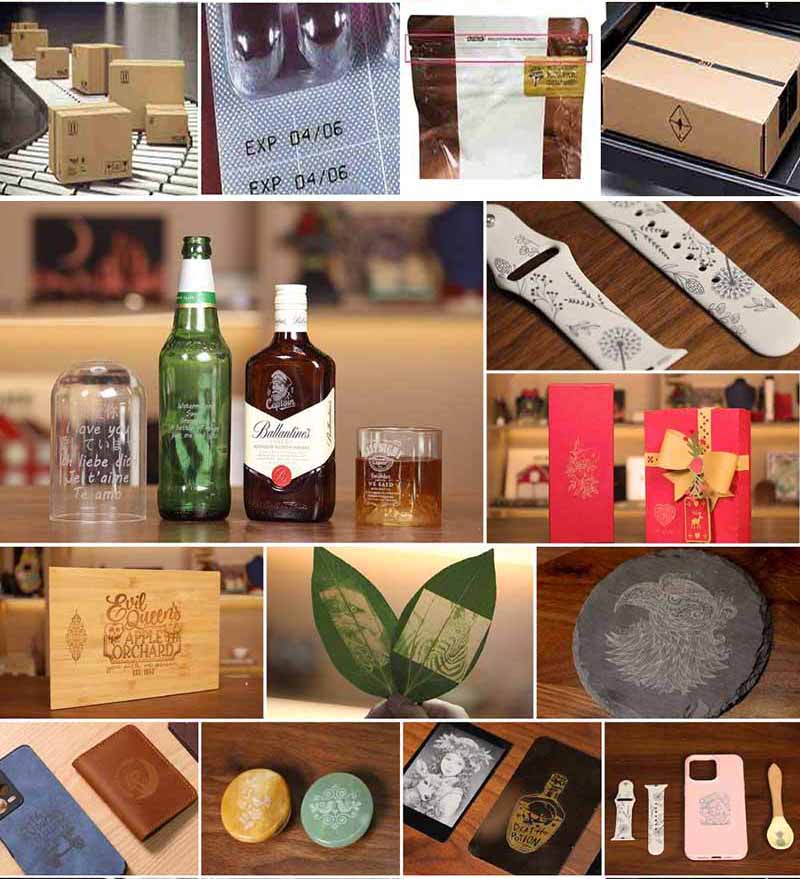

Yes, it is safe. The process involves no chemical reactions; instead, it uses a light beam to mark the surface of the object. The UV laser marking machine employs a non-contact, consumable-free physical marking method, making it ideal for a wide range of food and pharmaceutical products, as well as their packaging materials—such as fruit peels, eggshells, and milk packaging bags. It can directly engrave essential information, including brand names, places of origin, production dates, QR codes, and traceability codes, onto the product surface. This provides both anti-counterfeiting and traceability benefits. As a result, UV laser marking is widely used in high-end food packaging, cosmetic packaging, pharmaceutical packaging.

The UV laser marking for packaging are clear, long-lasting, and resistant to fading or peeling, eliminating problems associated with adhesive labels falling off or inkjet printing causing contamination. Food can still be stored long-term after marking, with no impact on edibility, fully meeting both food safety and environmental protection standards.

Why Use UV Laser Marking on food Packaging?

UV laser marking enables the creation of permanent, high-quality markings on bottles and packaging, avoiding the high costs and environmental pollution associated with inks or chemicals. Its low thermal impact ensures the integrity of sensitive materials.

Non-Contact Processing

UV laser marking uses a high-energy UV beam to burn or etch directly onto the surface of packaging materials (such as plastic, metal, glass, etc.), without the need for any ink, solvents, or chemicals. The process causes only physical changes to the material (e.g., surface carbonization or color modification), eliminating the risk of chemical contamination at the source and complying with strict FDA standards.

No Consumables Required

Traditional marking methods require frequent replacement of inks and solvents, which may introduce chemical contaminants during storage and transportation. UV laser marking machines, on the other hand, operate without any consumables—only consuming electricity—with no emissions of gases, liquids, or solid waste during use. This leads to reduced production costs by eliminating the need for ink and coatings.

Durable, Permanent, and Accurate

Laser markings on food packaging are long-lasting and highly precise. Unlike ink or stickers, laser marks do not fade, ensuring that important information remains clear and legible. For example, production dates marked on plastic packaging or bottle labels remain intact even after alcohol wiping, high-temperature sterilization, or prolonged contact with chemical ingredients—avoiding common issues like blurring or peeling associated with traditional ink printing.

High Precision and Resolution

Food and pharmaceutical packaging often requires detailed information such as batch numbers, expiration dates, and traceability codes. UV laser marking achieves micron-level precision (typically ≤50μm), allowing clear QR codes to be marked even on very small surfaces (e.g., a 1cm-diameter bottle cap) with clean edges and no burrs or ghosting.

Non-Damaging Marking

Unlike traditional laser methods that generate a heat-affected zone (HAZ), UV lasers operate at lower temperatures, preventing damage to the base material and preserving the integrity of sensitive substrates.

Compatible with Various Packaging Materials

Food and pharmaceutical packaging involves a wide range of materials, including polyethylene, polypropylene, glass, and aluminum foil, etc. Due to its wavelength characteristics, UV laser marking is highly adaptable to most non-metallic materials and some metallic surfaces.

What Kind of Packaging Materials are UV Laser Marking Used for?

1. Flexible Packaging Materials

With its short wavelength (typically 355nm) and finely focused beam, UV laser marking is ideal for high-precision marking on heat-sensitive, thin film materials such as PE, PET, and PP. Common applications include:

- Food and pharmaceutical packaging bags

- Aluminum-plastic composite films (e.g., blister packs)

- Soft packaging for personal care products

Typical markings include production dates, expiration dates, QR codes, and barcodes. The process ensures fine, clear results with no heat-affected zone (cold marking), does not penetrate the material, and preserves the integrity of the package’s seal.

2. UV Laser Marking Plastic

UV laser marking is highly compatible with plastics such as PET, PVC, and polystyrene:

- No additives or pre-treatment required

- Markings are durable and scratch-resistant

- Micron-level precision supports small QR codes and traceability codes

Widely used on bottle bodies, caps, plastic bags, outer packaging bags and labels.

3. Eco-Friendly Marking on Organic Materials

UV laser marking is a non-contact process that does not use ink or chemical solvents, making it a truly eco-friendly technique—especially suitable for:

- Natural fiber labels

- Eco-friendly plastic packaging

- Biodegradable materials

The process emits no harmful byproducts and aligns with green manufacturing trends.

4. Paper and Cardboard

UV laser marking is suitable for all types of packaging paper, cartons, and cardboard surfaces:

- No bubbling or scorching; surfaces remain clean

- Supports high-speed processing and automation

- Markings are clear, permanent, fade-resistant, and smudge-proof

Commonly used for marking QR codes, brand logos, and regulatory codes on cigarette packs, pharmaceutical boxes, and gift boxes.

5. Glass Packaging

Using laser micro-engraving, patterns can be marked on glass bottles without compromising the structural integrity of the glass.

6. Metal Foils

For pharmaceutical aluminum foil sealing films, UV laser can precisely control energy to create a visible color change on the surface without penetrating the material, preserving its barrier properties.

5W UV Laser Marking Machine

The 5W UV laser marking system is specifically designed for ultra-fine processing in high-end industries, where precision and material compatibility are critical. It delivers high-contrast, heat-free, non-contact, and permanent markings on a wide range of polymer packaging materials commonly used in cosmetics, pharmaceuticals, and food industries—such as PET, HDPE, PVC, PE, coated aluminum foil, and glass. The marking is exceptionally clear, delicate, and firmly attached to the surface, offering a superior alternative to traditional inkjet printing methods while being more eco-friendly and reliable.

Beyond packaging, this machine is widely applied in flexible PCB marking, micro-drilling and blind hole processing on silicon wafers, QR code engraving on LCD glass, engraving on glassware surfaces, coating removal on metal surfaces, and high-precision marking or micro-processing on plastic keypads, electronic components, personalized gifts, and more.

DPLaser UV laser marking machine integrates advanced galvo scanning, high-speed marking capabilities, and a user-friendly interface. It’s a powerful tool for manufacturers looking to upgrade traceability, branding, and regulatory compliance through precision laser technology.

Ultra-Fine Marking Precision

With an extremely small laser spot and minimal heat-affected zone, the UV laser marking machine is capable of achieving micron-level marking precision down to 0.01mm, making it ideal for high-end, delicate applications.

Non-Contact & Thermal Damage-Free Processing

As a cold-processing technology, UV laser marking does not generate heat buildup, preventing deformation, scorching, or melting. It is especially suitable for marking plastic films, soft packaging, and heat-sensitive materials.

Broad Material Compatibility

This UV laser marking system supports high-quality marking and micro-processing on a wide range of materials, including glass, ceramics, plastics, polymers, silicon wafers, and metal coatings.

High-Contrast, Permanent Marking

UV laser markings are highly legible, stable, and permanent. They resist smudging, fading, or damage during transportation or storage—making them ideal for product traceability, anti-counterfeiting, and tamper-evidence in cosmetics and pharmaceutical industries.

Eco-Friendly & Consumable-Free

The 5W UV laser system requires no ink, solvents, or consumables. It produces no odor or secondary pollution, fully complying with strict environmental and hygiene standards in food and medical packaging.

Versatile Packaging Compatibility

This UV laser engraving machine easily adapts to various packaging formats, including bottles, caps, boxes, soft pouches, labels, and tubes. It integrates seamlessly with production lines for high-speed, real-time marking.

High-Speed Automation & Labor Savings

Equipped with high-performance galvo scanners and intelligent control systems, it supports 24/7 continuous operation, increasing output and reducing reliance on manual labor.

Flexible Integration Options

The UV laser marker can be configured as a standalone desktop unit, integrated into automated equipment, or customized as a workstation—flexibly meeting the needs of diverse manufacturing environments.

Our UV laser marking machine stands out as a highly precise, efficient, and eco-friendly solution for high-end packaging and micro-processing needs. With its cold processing technology, broad material compatibility, and ability to deliver permanent, high-contrast marks without consumables, it meets the strict requirements of industries like food, cosmetics, pharmaceuticals, and electronics. Its flexibility, marking speed, and seamless integration into automated production lines make it an ideal choice for manufacturers seeking reliable, high-performance marking solutions.

Final word, UV laser marking on food packaging provides a safe, clean, and highly precise solution for traceability, branding, and regulatory compliance. Its non-contact, cold processing ensures zero contamination and maintains the integrity of sensitive packaging materials. As industries move toward eco-friendly and permanent marking technologies, UV laser marking systems are proving to be the ideal choice for packaging applications across pharmaceuticals, cosmetics, and food products.