3D laser marking technology is specifically designed for complex shapes, making it easy to mark curved, slanted, and cylindrical surfaces that are challenging for traditional 2D marking methods. By intelligently adapting to the geometric curvature of the workpiece, it delivers high-precision, detailed, and durable markings. Compared to conventional approaches like manual repositioning or using rotary axes, an industrial 3D laser marking system offers advanced dynamic focusing and spatial positioning capabilities, making it a key technology in driving production upgrades across industries such as mechanical manufacturing, automotive manufacturing and medical device fabrication.

How Does a 3D Fiber Laser Marking Machine Work?

A 3D laser marking machine operates by generating a high-energy laser beam through laser excitation. This beam is transmitted and modulated via an optical system, and finally, focused precisely onto the surface of the workpiece using optical lenses to perform marking. The focused high-energy laser ablates the surface of the material, leaving a permanent mark.

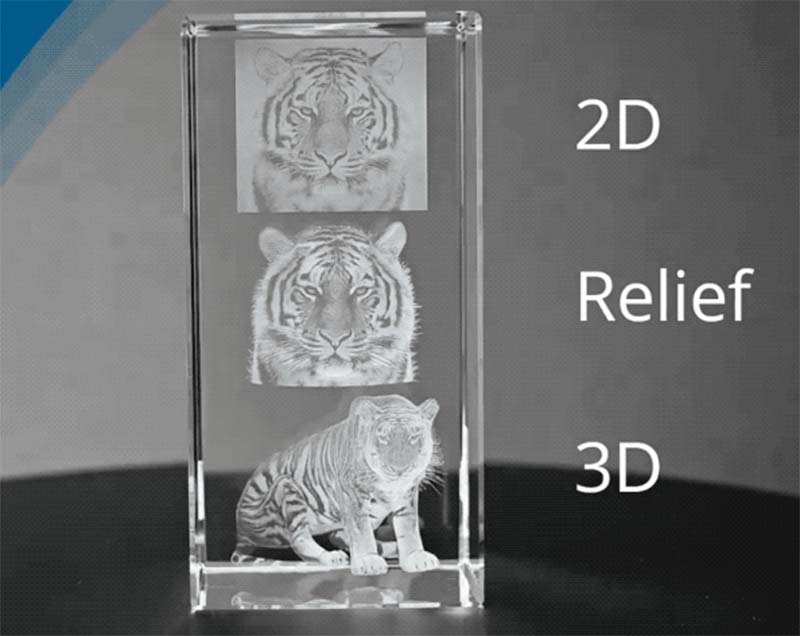

Traditional 2D laser marking is limited to flat or slightly curved surfaces and has a restricted marking range. In contrast, 3D laser marking uses software-controlled dynamic Z-axis and XY-axis galvanometers to precisely position and adjust the laser focus in three-dimensional space in real time. The system is equipped with a dynamic focusing lens capable of zooming and beam expansion, allowing the laser to maintain optimal focus on surfaces at varying heights. This enables high-precision marking on complex three-dimensional structures.

Advantages of 3d Laser Marking For Manufacturing

As an advanced laser processing device, the 3D laser marking machine has become an indispensable high-end manufacturing tool across various industries, thanks to its comprehensive advantages in marking precision, material adaptability, curved surface processing capability, and production efficiency.

High-Precision Marking

The industrial 3D laser engraving machine achieves micron-level precision, ensuring that patterns, characters, and QR codes are engraved with sharp clarity. This meets the high marking accuracy requirements of applications in electronics, medical devices, aerospace, and other precision-demanding fields.

Adaptability to Multiple Materials and Shapes

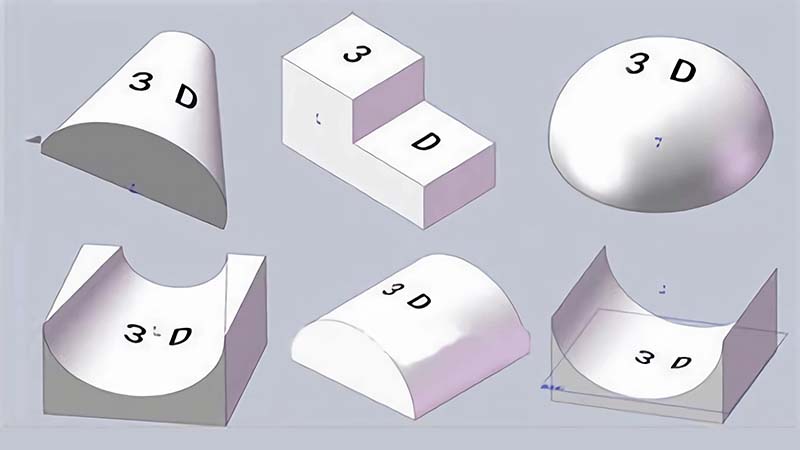

3D laser marking equipment is compatible with a wide range of materials, including metal, plastic, ceramic, glass, and wood, flexibly addressing diverse marking needs. Whether flat, curved, conical, spherical, cylindrical, or irregularly contoured surfaces, it delivers precise engraving, enabling a perfect blend of creativity and functionality.

Accurate Marking on Complex Curved Surfaces

With the help of 3D dynamic focusing technology, the machine accurately adapts to spherical, cylindrical, conical, and multi-level uneven surfaces. It eliminates the need for frequent clamping or rotating of the workpiece, easily achieving uniform, continuous, and high-quality laser marking.

Deep Relief and Embossing Capabilities

The 3D laser marking machine supports deep engraving, embossing, and relief carving, meeting the demanding depth and detail requirements of high-end applications. It is widely used in nameplate manufacturing, mold processing, and custom artwork production.

Efficient and Intelligent Production

Laser marking system integrates seamlessly with automated production lines, offering rapid response times suitable for large-scale continuous processing. It significantly boosts productivity while reducing manual intervention and optimizing production costs.

Industrial 3D Laser Engraving Machine Applications

3D laser marking machines have become essential equipment in the field of precision marking due to their non-contact processing, flexible focusing, and ability to adapt to complex surfaces. These machines can produce high-precision, high-contrast, and permanent markings on various materials and irregular surfaces, making them widely applicable across numerous industrial manufacturing sectors.

Automotive Parts Marking

Used for marking serial numbers, QR codes, and product traceability information on complex curved surfaces such as engine casings, brake discs, and exhaust pipes. The markings are resistant to high temperatures and corrosion, ensuring quality control and post-sale traceability.

Hardware and Mold Marking

Enables high-precision marking on uneven or curved mold surfaces, including mold serial numbers, workstation codes, and safety symbols, all without the need to change fixtures—showcasing strong adaptability.

Machinery Component Identification

Provides permanent laser engraving of product IDs, brand logos, and usage instructions on mechanically complex components, enhancing product traceability and anti-counterfeiting capabilities.

Tool and Cutter Marking

Applies accurate markings—such as model numbers, production batches, and specification details—on cylindrical or conical surfaces of drills, cutters, and blades, enabling precise identification and error-proof management.

Industrial Pipes and Fittings Marking

Performs corrosion-resistant laser marking on bent or irregular stainless steel pipes, valves, and joints, making it ideal for labeling in clean industries such as petrochemicals, food processing, and pharmaceuticals.

Industrial Equipment Nameplates and Information

High-speed laser engraving of dynamic QR codes, parameter information, warranty numbers, and other details on metal nameplates for industrial equipment, enhancing tamper resistance of the markings.

Marking on Motors and Transmission Components

Axial rotational marking on circular parts such as motor housings, gears, and bearings, seamlessly integrated with production lines for intelligent continuous operation.

Bicycle Frames / Sports Equipment (Oval or Irregular Tubes)

For irregular tube structures like aluminum bike frames, skis, and rackets, 3D laser marking can permanently engrave patterns or brand logos on the tube surfaces.

Cosmetic Bottle Caps / Medical Bottles (Cylindrical or Curved Packaging)

Suitable for personalized text, graphics, or traceability codes on plastic or glass bottle caps and bodies. Even with curvature variations on the bottles, 3D marking achieves uniform, continuous, and distortion-free results.

Light bulbs and tubes (Cylindrical Glass/Plastic/Metal Surfaces)

Laser marking of brand logos, technical parameters (voltage, current), certification marks (e.g., CE, RoHS), and QR codes on surfaces of LED bulbs, tubes, and smart lighting housings. The 3D laser marking machine’s dynamic focusing and curvature auto-compensation allow distortion-free, continuous, high-resolution circular or curved markings without rotating the workpiece.

3D Dynamic Focus Laser Marking Machine

The 3D dynamic focus laser marking machine utilizes advanced dynamic zoom technology to achieve precise laser marking of complex patterns on uneven, curved, inclined, or multi-level surfaces. Its outstanding performance and wide material compatibility make it highly suitable for precision processing needs in industries such as automotive, electronics, medical, hardware, molds, and lighting.

Features:

Advanced Laser Marking Solution

As product traceability requirements continue to rise across industries, the ability to achieve precise marking on various substrates has become critical. Using UV three-axis laser marking technology, it supports multiple marking formats including Data Matrix codes, QR codes, and serial numbers.

Ultra-Micro Area High-Precision Non-Destructive Marking

To meet the marking demands of miniaturized components like semiconductor chips, the machine can perform high-definition laser engraving within extremely small spaces, ensuring distortion-free patterns.

High-Contrast Marking on Various Materials

Employing a short-wavelength laser beam with finer focusing and more precise energy control, it delivers clear, high-contrast markings on complex metals, acrylic, wood, glass, ceramics, resin, and other hard-to-process substrates.

How to Choose the Right 3D Laser Marking Machine for Industrial 2025?

When selecting a suitable 3D laser marking machine, it’s important to consider multiple key factors such as material type, marking speed, precision, and budget. The following guide will help you make an informed decision:

1. Clarify Your Needs

- Application Scenarios and Materials: First, identify the specific purpose of the laser marking machine and confirm the types of materials to be processed, such as metal, plastic, glass, ceramics, etc.

- Precision and Speed Requirements: Determine the required marking precision and speed based on the characteristics of your marking tasks. Different applications demand varying levels of accuracy and efficiency.

- Laser Type Selection:

Fiber Laser: Suitable for efficient marking on metals and some plastics.

CO₂ Laser: Better suited for non-metal materials like wood, leather, and glass.

UV Laser: Designed for ultra-fine marking on sensitive materials such as electronic components and food packaging.

2. Marking Area and Engraving Depth

Workpiece Size Compatibility: Confirm whether the marking area can fully cover your workpiece, considering its shape and size.

Top 3D Laser Marking Machine Brands 2025

The following are globally 3D laser marking machine leaning brands, evaluated comprehensively based on technological innovation, market recognition, and industry influence:

TRUMPF (Germany)

A global technology leader in industrial lasers.

As a representative of Germany’s high-end equipment manufacturing, TRUMPF’s 3D laser marking systems integrate advanced dynamic focusing modules and energy adaptive control algorithms, achieving micron-level high precision marking. It is especially suitable for deep engraving and curved surface processing of hard materials like stainless steel and ceramics. Widely used in automotive, mold, and aerospace high-end manufacturing sectors.

DP Laser (Dapeng Laser, China)

A core supplier in China’s 3C electronics market.

As a leading domestic laser equipment manufacturer, Dapeng Laser’s 3D fiber marking machines feature five-axis linkage combined with a self-developed intelligent vision positioning system, making them ideal for marking irregular parts and precision electronic components. They enjoy strong customer loyalty and a large installed base in 3C electronics and communication devices.

IPG Photonics (USA)

Original manufacturer of fiber lasers with strong 3D marking performance.

Known for its fiber laser technology, IPG’s LightWELD 3D system features dynamic zoom and path adaptive control, suitable for marking on various complex surfaces. Particularly effective in microstructure processing of medical devices, it achieves marking speeds up to 8000 mm/s and offers about 30% energy savings compared to traditional equipment.

HGTECH (Huagong Laser, China)

Experts in marking for new energy and highly reflective materials.

Leveraging Huazhong University of Science and Technology’s strong research base, HGTECH has overcome the challenges of processing highly reflective materials like copper and aluminum. It is especially suited for precise and efficient coding and marking in new energy batteries and power modules.

Raycus (China)

Pioneer in domestic laser sources with modular design advantages.

Raycus is a core enterprise in China’s fiber laser industry. Its 3D marking machines support multiple laser source switching (e.g., CO₂, UV, green light) and feature modular structures, suitable for fine processing of fragile materials like plastic and glass. The production yield reaches 99.5%, widely used in crafts and precision components manufacturing.

JPT (JPT Photonics, China)

Leader in ultrafast laser technology.

JPT excels in MOPA pulsed fiber laser technology. Its MOPA 3D marking equipment offers adjustable pulse widths from 1 to 200 ns and, combined with six-axis collaborative robots, can efficiently remove oxide layers and perform fine marking on complex curved surfaces. Its market share in semiconductor wafer processing has grown rapidly in recent years.

Finally, DP laser industrial 3D laser engraving machines are capable of producing intricate three-dimensional engravings on a wide range of materials, including wood, acrylic, ceramics, metals, and glass. These machines can carve complex patterns with rich depth and texture, making them ideal for personalized products and high-end engraving applications. As a leading laser equipment manufacturer in China, our company offers a diverse range of 3D laser engraving solutions tailored to meet the production needs of businesses ranging from small enterprises to large-scale factories.