Brittle and heat-sensitive materials have long posed significant challenges in the field of precision manufacturing. These materials are easy to cracking or burning during processing, making it difficult for traditional methods to achieve high accuracy and acceptable yield rates. With the ultrashort pulse and high peak power lasers in recent years, ultrafast laser processing—especially picosecond lasers and femtosecond lasers—has shown tremendous potential in upgrading glass fabrication and enhancing material performance. This article explores how picosecond lasers are used in processing fragile and sensitive materials, offering some of the best laser marking sensitive materials solutions available today.

Laser Marking of Sensitive Materials

- Temperature Sensitivity

Certain high-precision materials—such as specialty plastics, composite panels, and ultra-thin metals—are highly sensitive to temperature fluctuations. Improper laser power settings may cause warping, scorching, carbonization, or material degradation.

- Physical Fragility

Brittle materials, including optical glass, precision ceramics, and some advanced engineering plastics, are prone to cracking under mechanical stress. High-precision marking techniques are required to prevent micro-cracks or internal structural damage.

- Chemical Stability

Some materials may undergo molecular changes when exposed to laser irradiation, potentially altering their properties or surface characteristics. Strict control of process parameters is essential to ensure material stability during laser interaction.

Ultrafast Laser Marking Technology

Ultraviolet picosecond lasers represent an advanced laser technology characterized by extremely short pulse durations and high energy density. This unique combination enables strong non-thermal interactions with material surfaces, allowing for highly precise micro-scale processing.

Key Advantages of Ultrafast Laser Processing Sensitive Materials

- Non-Thermal Effects:

Due to the ultrashort pulse duration, heat does not have time to diffuse into surrounding areas. This allows for precise material removal or modification with minimal thermal impact, preventing thermal damage.

- Ultra-High Precision Machining:

The minimized heat-affected zone (HAZ) enables processing at micron or even nanometer resolution. This makes uv picosecond lasers ideal for precision micromachining, especially for heat-sensitive materials.

- Material Selectivity:

Ultrashort pulses can selectively remove surface coatings or specific material layers without damaging underlying substrates—similar to restoring a valuable painting by removing only the surface contamination while preserving the original pigments.

- High Processing Efficiency:

Although individual pulses carry relatively low energy, their repetition rates can reach the megahertz range. This ensures high overall processing throughput.

- High Flexibility:

With computer numerical control (CNC) programming, picosecond laser marking systems can easily execute intricate designs—whether straight lines, curves, complex geometries, custom cuts, or micro-drilling—with exceptional precision and repeatability.

These characteristics give UV picosecond laser micromachining systems unique advantages in the field of precision microfabrication, making them particularly suitable for processing heat-sensitive materials such as brittle substrates and composites.

Ultrafast laser marking offers significant benefits for both surface marking and internal engraving of brittle materials. They can produce clear, uniform markings on the surfaces of glass, sapphire, ceramics, and other fragile materials—without deformation or thermal damage. The system supports large-area processing with high efficiency and is also capable of marking on curved brittle surfaces.

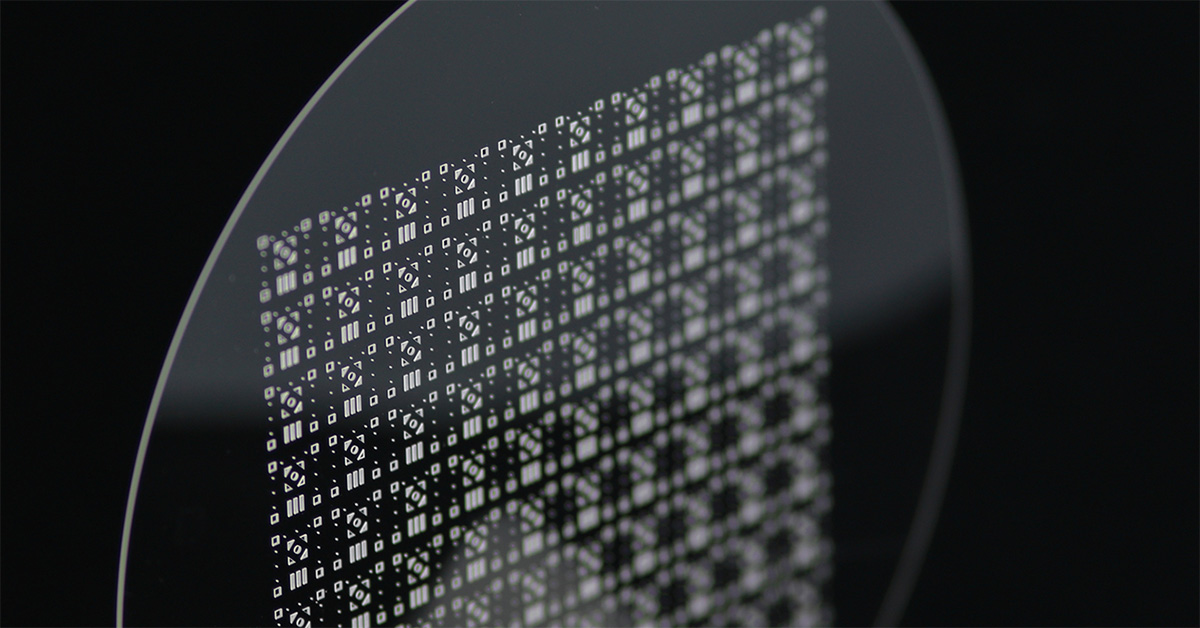

In the semiconductor industry, ultraviolet picosecond lasers enable nano-level fabrication of fine structures while preserving the original physical and chemical properties of the materials.

Infrared Picosecond vs. UV Picosecond Lasers

Infrared picosecond lasers generate a small amount of heat during processing, which may not be suitable for certain heat-sensitive materials. However, for materials that benefit from a degree of thermal interaction—such as metals and ceramics—infrared picosecond lasers can offer distinct advantages, including enhanced material response and improved processing efficiency.

In contrast, UV picosecond lasers operate at much shorter wavelengths, typically in the sub-400 nm range. This results in a significantly smaller focal spot size, enabling ultra-high precision machining. UV laser marking is widely used on sensitive surfaces, including marking, cutting, micromachining, and precision manufacturing.

Thanks to their minimal heat-affected zone (HAZ), UV picosecond lasers achieve near “cold” processing, causing little to no thermal damage to the material. This makes them especially well-suited for delicate substrates such as glass, acrylic and plastics. In addition, UV picosecond lasers offer high beam quality and fast processing speeds, making them a versatile solution for demanding microfabrication tasks.

Application of Laser Etching Heat Sensitive Material

Picosecond laser marking system is widely applied to the processing of sensitive materials, including QR code marking for traceability, cutting, drilling, and film removal. In semiconductor applications—such as ingot rounding and core extraction, as well as complex wafer shaping of materials like monocrystalline silicon, sapphire, silicon carbide, FPC, PCB, and CVD diamond—ultrafast lasers offer critical advantages. Ultrafast lasers, with their No thermal effects, crack-free processing, and smooth cutting surfaces, can meet the stringent requirements of advanced chip and optoelectronic device manufacturing.

Laser Marking Heat Sensitive Material

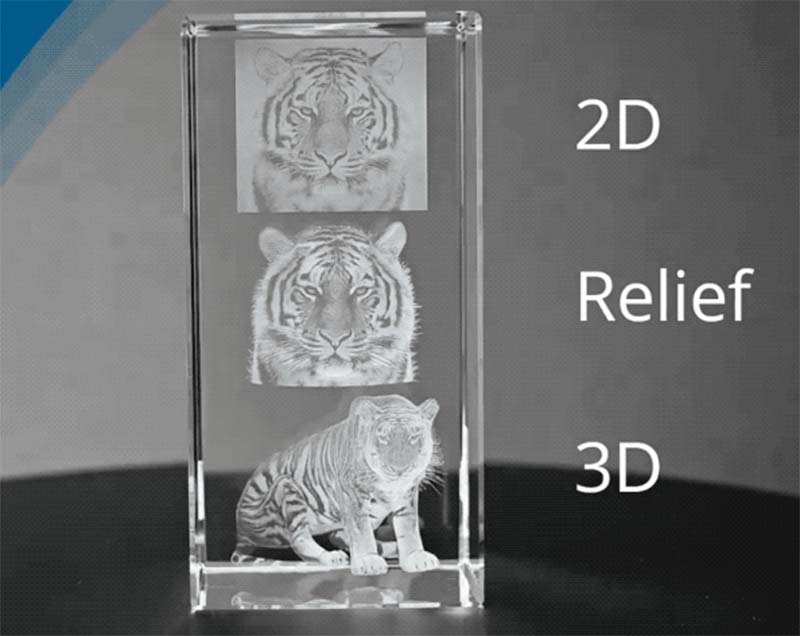

Laser marking of sensitive materials mainly includes two methods: surface engraving and internal glass engraving.

Surface marking is achieved by directing a high-energy laser beam, focused onto the glass surface. When the laser energy density reaches the material’s damage threshold, the surface material instantly melts and vaporizes. By precisely controlling the laser’s movement path across the surface, localized material removal creates the desired marking pattern. When using picosecond lasers for surface marking, the extremely small heat-affected zone prevents thermal deformation and significantly reduces internal stress. The marked glass surface feels smooth to the touch with no noticeable roughness, and the marking dots appear crisp and clear.

Picosecond laser marking machines have been widely adopted in the semiconductor chip industry for QR code traceability, especially for internal marking within glass. By applying very low pulse energy, the refractive index of the processed area changes locally, creating a small dot without affecting the material’s properties or strength. Since QR codes are typically small (around 0.2 × 0.2 mm) and invisible to the naked eye, dedicated instruments are used to trace the production process of the product.

Internal glass engraving involves focusing the laser beam inside the glass. High-energy laser pulses create micro- to millimeter-scale micro cracks within the glass. These cracks scatter light, appearing white, and by controlling the laser path, desired patterns are engraved inside the glass.

Laser Cutting Heat Sensitive Material

Picosecond laser cutting technology is widely applied in the separation and cutting of heat-sensitive and transparent brittle materials. It is commonly used for precision cutting of glass substrates, glass cover plates, display panels, and camera lenses in electronic products, and its application can also be extended to fields such as photovoltaic glass.

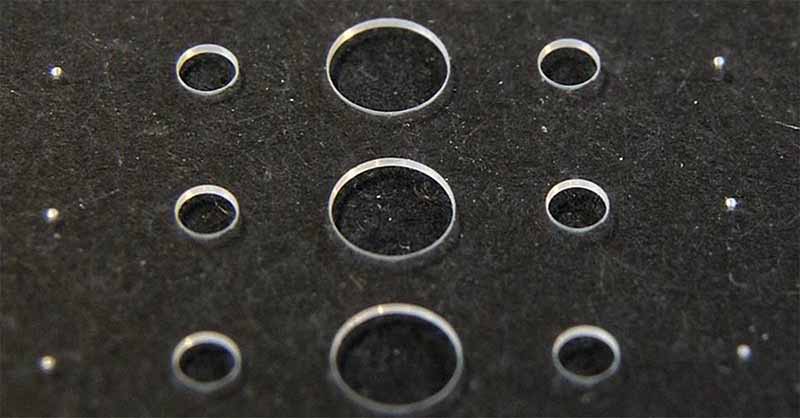

Laser Drilling Heat Sensitive Material

Compared to mechanical drilling, laser drilling of glass offers several advantages: non-contact processing, no consumables, flexible shape customization, pollution-free operation, and no need for additional water cooling. With the continuous growth of the photovoltaic industry, glass backplanes have become a critical component with high market demand. One key technology for glass backplanes is glass drilling. Typically, backplane glass requires reserved wiring holes and often involves complex-shaped holes, which traditional mechanical drilling struggles to meet in terms of efficiency and quality. Currently, fiber lasers are widely used for drilling photovoltaic glass.

Furthermore, in micro-hole drilling of glass for electronic devices, picosecond lasers combined with chemical wet etching can produce deep holes with high aspect ratios and virtually no cracks, meeting stringent quality requirements.

Laser Film Removal

Laser film removal primarily utilizes a high-energy laser beam focused on the surface of the film to be removed, causing rapid vaporization and delamination of the film layer. This process typically employs laser wavelengths that are highly absorbed by the film but minimally absorbed by the substrate. Laser parameters are carefully adjusted so that the energy density remains between the damage thresholds of the film and the substrate, preventing damage to the underlying material.

Traditional film removal methods, such as mechanical grinding and chemical etching, are contact-based processes that suffer from low precision, potential damage to the glass substrate, and environmental concerns.

Currently, industrial-grade picosecond lasers are widely applied in semiconductor wafer processing, display panel cutting, and thin-film solar cell die-cutting. With ongoing improvements in laser pulse energy, average power, and stability, picosecond laser technology is expected to achieve even greater breakthroughs in high-precision, high-efficiency processing in fields such as new energy lithium batteries, photovoltaic silicon manufacturing, defense, and aerospace.

Which Materials Are Suitable for UV Laser Marking on Sensitive Surfaces

1. Plastics

UV laser marking relies on photochemical reactions rather than thermal effects to create clear and durable marks on plastics such as PVC, PC, ABS, PP, and PE. This approach prevents material deformation or carbonization, effectively eliminating thermal damage issues common in traditional laser processing.

2. Glass and Crystal

As a non-contact cold processing technique, UV laser marking completely eliminates the risk of thermal damage, enabling delicate, crack-free markings on fragile glass and crystal surfaces.

3. Ceramics

UV picosecond laser marking systems are also well suited for ceramics. Whether unglazed or glazed, ceramics can be marked with clear, permanent patterns using UV lasers.

4. Silicon Materials (Semiconductor-Grade Precision)

For heat-sensitive semiconductor components such as silicon wafers and chips, UV laser marking offers ultra-fine marking and cutting while avoiding heat-affected zones (HAZ) that could interfere with electrical performance.

5. Rubber and Leather

Ultraviolet picosecond laser marking is also applicable to rubber and leather materials, producing precise patterns and text without scorch marks or edge carbonization.

6. Metals

Although not the mainstream choice, UV laser marking can still achieve cold marking on metal surfaces like stainless steel and aluminum. This is particularly suitable for high-precision parts sensitive to thermal deformation.

Laser marking offers high precision and low thermal impact for a wide range of heat-sensitive and brittle materials, including plastics, glass, ceramics, semiconductors, metals, rubber, and leather. It enables permanent, high-quality markings with minimal heat damage, making it an ideal solution for electronics manufacturing and precision applications. In applications where precision and minimal thermal impact are critical, UV laser marking on sensitive surfaces proves to be an outstanding solution. From delicate polymers and coated metals to brittle ceramics, glass and transparent materials, UV picosecond lasers ensure clean, high-contrast marks without compromising structural integrity. As industries continue to demand higher quality and reliability, adopting laser marking for sensitive materials will remain a forward-thinking and effective choice.