In manufacturing and customization industries, the need for flexible and efficient laser marking solutions is greater than ever. A dual-source laser marking machine stands out by combining the power of two laser technologies in one system—allowing you to mark many different materials with high precision and speed. The dual-source laser marking system allows you to quickly and easily select the most suitable laser source for your application. Depending on the system configuration, you can switch between laser sources or operate them simultaneously, simply by setting the working time for each source. This flexibility greatly enhances the versatility of the system, making it an ideal laser marking machine for different materials.

Does Your Product Contain Multiple Materials?

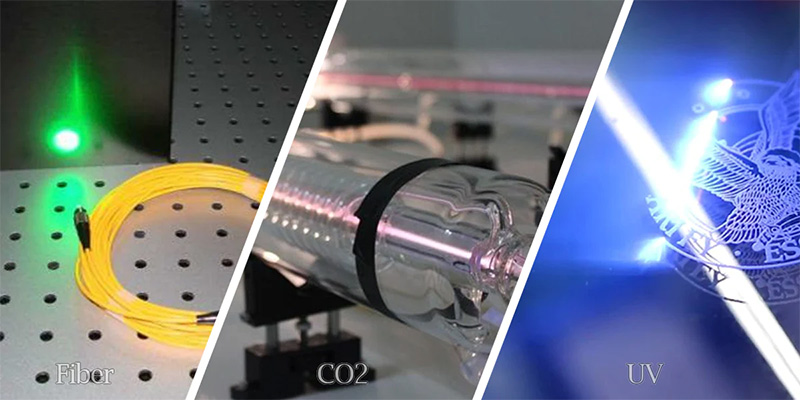

Our dual-laser source laser marking machine for metal & non-metal integrates both fiber laser and CO₂ laser source, leveraging the complementary characteristics of each source to meet a wide range of marking and engraving needs.

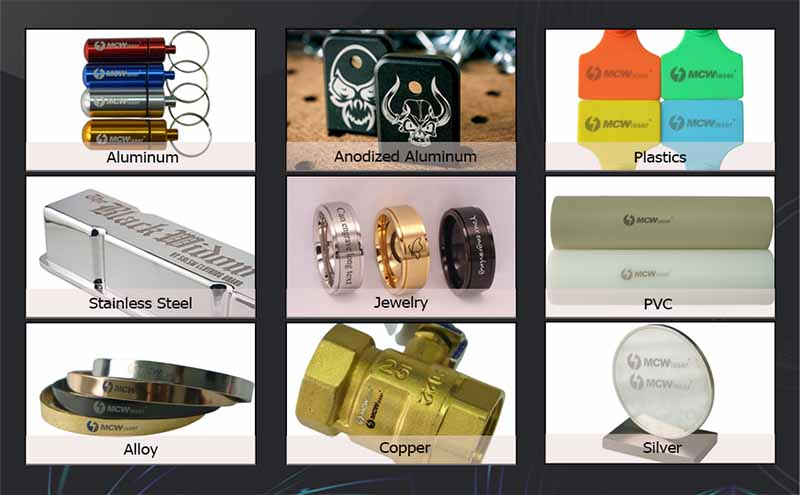

The dual-laser system allows you to configure the use of either the CO₂ laser(for non-metal materials such as wood, acrylic, leather, fabric, and rubber) or the fiber laser, which is ideal for marking and engraving metals like stainless steel, aluminum, and carbon steel.

This versatile setup makes it the perfect solution for processing products made from multiple materials, enabling precise and efficient marking on both metal sheets and a variety of non-metal substrates.

Advantages of Double Source Laser Marking Machine

1. Space-Saving Design

If your workshop can only accommodate one machine, a dual-source laser system is an excellent way to maximize performance without expanding your workspace. With a dual-laser engraving machine, you can handle multiple marking tasks using just one device, significantly reducing the number of machines required. Designed with efficiency in mind, it offers multi-material processing capabilities within a compact footprint. This is the key distinction between a dual-source laser marking system and two separate CO₂ and fiber laser marking machines.

2. Enhanced Reliability

The dual-source laser marking machine virtually eliminates downtime. When one laser source requires maintenance or replacement, the other can continue operating immediately, ensuring uninterrupted and stable production.

3. Expanded Material Processing Capabilities

If your business focuses on a specific type of material, a single-laser marking machine may serve you well. However, as your engraving needs evolve, this specialization can become a limitation. A dual-source laser marking machine—integrating both fiber and CO₂ laser technologies—significantly expands material compatibility within a single unit.

By enabling users to select between two different wavelengths (1064 nm for fiber laser and 10.6 μm for CO₂ laser), the system allows seamless marking on a wide variety of materials. With this setup, you essentially get a Laser Marking Machine for All Materials.

This capability allows you to mark different surfaces of a single workpiece in one processing cycle, reducing production time. It supports both thin metal sheets (such as stainless steel, aluminum, and galvanized sheet) and a range of non-metal materials (wood, leather, acrylic, and more). This flexibility meets diverse material and process requirements without compromising efficiency.

4. Easier Production Line Upgrades

If you only occasionally need to use a fiber laser, the dual-source option is an excellent way to expand your material processing capabilities without adding a second machine. This configuration offers high flexibility for your investment—users can start with a cost-effective setup and easily scale up the production line later.

When working together, the dual laser sources not only increase throughput but also fully leverage the unique advantages of both laser types.

Why Can Dual Source Laser Systems Achieve Higher Marking Efficiency?

The reason dual laser sources can improve efficiency is that during processing, speed is more critical than power. Single-head devices often waste power due to speed limitations. Dual laser sources can handle two workpieces simultaneously without changing the speed, effectively doubling productivity and avoiding power waste. Or process different materials of a product on the same production line.

Moreover, in low-power scenarios, dual laser sources not only overcome speed limitations but also offer advantages over high-power single lasers, including lower cost and higher technical feasibility.

Cost of Dual-Source Laser Marker

Single-source laser engravers are usually designed specifically for certain materials, resulting in lower upfront costs. If the business focuses solely on one type of material—such as engraving metal or wood—a single-source machine is a highly cost-effective choice. However, single-source devices lack scalability; if future plans involve expanding to other materials, additional machines must be purchased, which will inevitably increase the overall cost.

In contrast, although dual-source laser markers require a higher initial investment, you can use a laser marking machine for metal & non metal. They can handle multiple materials with a single system, and compared to buying multiple single-source machines, this one-time investment can save money in the future. This makes dual-source systems especially suitable for businesses anticipating expansion or needing to process different materials, turning the higher upfront cost into greater value.

Dual-Source Laser Marking Machine

The dual-source laser marking machine combines two laser technologies: fiber laser and CO2 laser, enabling precise adaptation for various material processing. The fiber laser specializes in metals, using high energy density to achieve fine marking and cutting instantly. Whether it is stainless steel, aluminum alloy, or precious metals, it delivers clear and durable marks. The CO2 laser excels in processing organic and mineral materials such as wood, leather, acrylic, and fabrics, producing delicate and detailed engravings. With both laser sources integrated into a single machine, you can use laser marking different materials efficiently to meet diverse requirements.

Marking & Cutting Functions of the Dual-Source Laser Marking Machine

By leveraging the synergy of fiber and CO₂ dual-source laser technology, this system builds an integrated high-precision marking and cutting solution.

For metal materials such as stainless steel and aluminum alloy, the fiber laser delivers high energy density to instantly achieve marking or cutting depths between 0.1 and 2 mm. The resulting marks are wear- and corrosion-resistant, and the cutting edges maintain a perpendicularity of up to 90°, making it ideal for applications like electronic component numbering and nameplate manufacturing.

For non-metal materials such as wood, leather, and acrylic, the system switches to CO₂ laser, which uses thermal conduction to perform micron-level fine engraving. This enables delicate hollow patterns on leather goods and precise pattern cutting on wood panels, producing smooth cuts without carbonization.

The accompanying intelligent software supports one-click import of CAD/AI design files, automatically generating marking paths and cutting trajectories without manual parameter adjustments. For example, in mobile phone case processing, the fiber laser first etches logos and specifications, then the CO₂ laser completes contour cutting of the plastic frame. The fully automated process improves efficiency by three times compared to traditional equipment while controlling errors within ±0.05 mm to meet high-precision industrial production requirements.

Versatile Functions, Unlimited Creativity

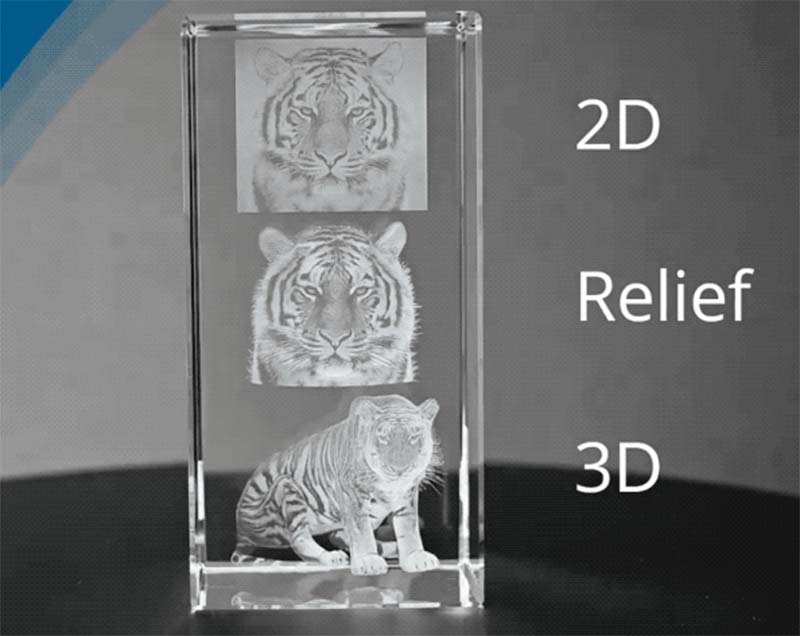

The fiber and CO₂ dual-source laser marking machine can be equipped with a UV laser source according to customer needs, converting it into a fiber & UV dual-source laser marking machine. The short-wavelength UV laser beam focuses with micron-level precision, enabling ultra-fine marking on very small surface areas. It is especially suitable for products demanding extreme precision such as electronic components and medical devices, ensuring clear marks with sharp edges without any thermal deformation or burn marks.

In terms of material adaptability, the UV laser breaks traditional barriers by exhibiting exceptional processing capability on plastics, glass, ceramics, and other materials that conventional lasers struggle to handle. Combined with the fiber laser, the UV laser source expands design possibilities, supporting complex patterns, gradient colors, and 3D embossing techniques.

Efficient Production, Time and Labor Saving

The coordinated operation of CO₂, UV, and fiber dual-source lasers enables one-step engraving across nearly all material types—including metals, wood, leather, and most plastics. This overcomes the limitations of traditional equipment that require frequent switching, significantly boosting production efficiency and reducing machine downtime, thereby helping businesses cut costs and improve productivity.

Service and Support: Dual-Source Laser Marking & Engraving Machine

Training Services

Our carefully designed training programs are dedicated to deeply enhancing your ability to utilize the full range of our solutions. The training covers comprehensive content including machine operation, professional software, and auxiliary accessories. Whether it’s equipment setup, software programming, or accessory functionality expansion, our expert instructors will share their knowledge openly to help you quickly master core technologies and maximize equipment performance.

Technical Support

Leveraging a global service network, we provide localized technical support in over 50 countries. Communication is conducted in local languages to ensure timely responses and seamless interaction. Working closely with our local distributors, who possess deep market insights, we deliver precise and attentive technical guidance. Whether you have questions about equipment usage, software troubleshooting, or special requirements, we respond promptly to give you peace of mind.

Maintenance Services

With extensive experience in laser equipment manufacturing, we have built a robust maintenance service system. More than 150 senior technical engineers are deployed across over 50 countries, collaborating with local distributors to form a wide-reaching, fast-response service network. From routine maintenance and emergency repairs to complex overhauls, we ensure your equipment is restored to optimal condition efficiently, minimizing downtime and operational losses.

In conclusion, choosing the right laser marking machine for different materials can significantly enhance production flexibility, marking quality, and long-term efficiency. With dual-source laser technology, you no longer need separate machines for metals and non-metals—one system can do it all. Whether you’re marking plastics, metals, ceramics, or composites, investing in a versatile solution ensures consistent performance across every application. If you’re ready to upgrade your marking capabilities or need expert advice, feel free to contact our team for tailored recommendations.