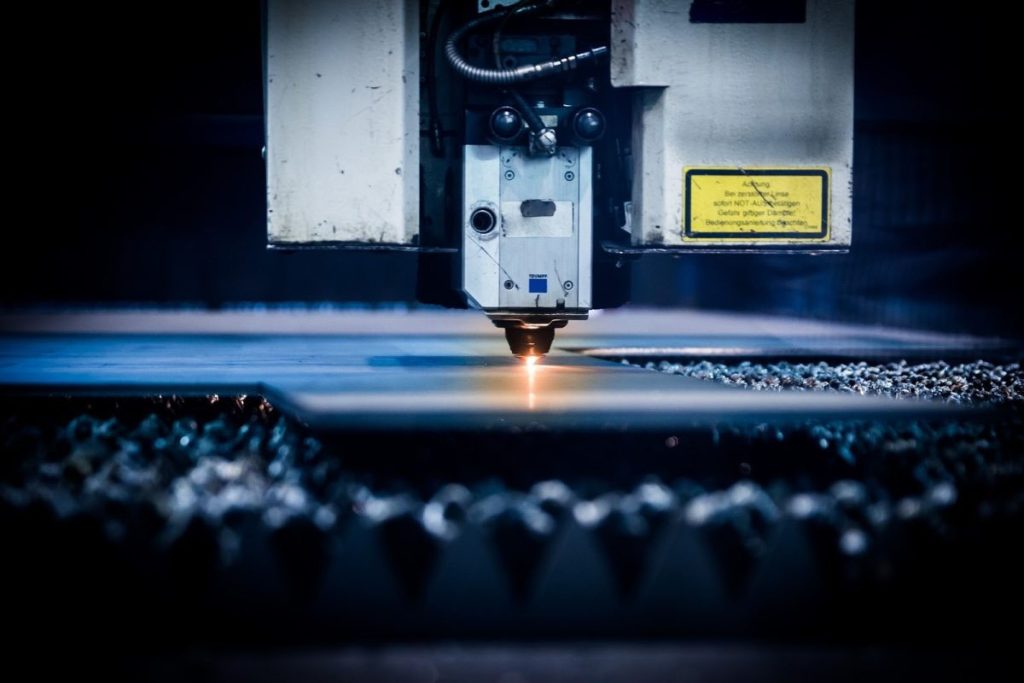

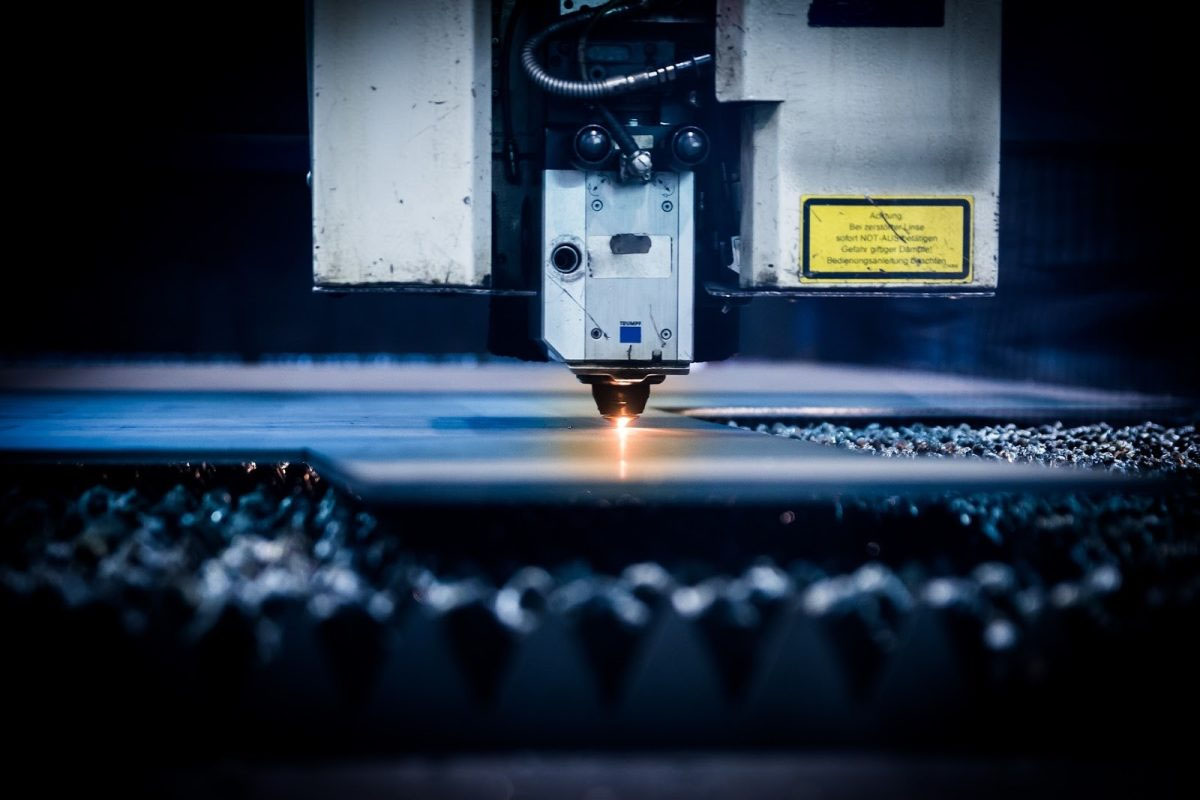

As the construction industry increasingly seeks lightweight, high-strength, and durable materials, metals and their composites have gained prominence for their exceptional physical properties. In the pursuit of high-quality and high-performance architecture, steel structures not only offer a superior alternative to traditional building materials but also open a new chapter in their application through the adoption of laser cutting technology. This article is about laser cutting in construction building.

Why Choose Laser Cutting for Construction?

Flame cutting was once the primary method for processing steel plates thicker than 40mm, suitable for initial rough cutting needs. However, while this method has a lower initial investment, it has significant limitations: it often leads to large thermal deformations during cutting, produces wider cut gaps that result in material waste, and has relatively low processing efficiency.

Plasma cutting offers higher precision and faster speeds compared to flame cutting, making it particularly effective for medium-thick plates. However, when cutting thin steel plates, it still faces issues such as thermal deformation and angle inconsistencies, which increase the complexity and cost of the finished product.

Laser cutting excels due to its high flexibility, speed, and efficiency, helping businesses quickly respond to market demands. It eliminates the deformation and tool wear issues typical of traditional cutting methods, and is suitable for a wide range of materials. Laser cutting produces narrow gaps and high-quality surfaces, with a system that is highly automated and easy to operate. This reduces manual intervention, supports optimized material nesting, improves material utilization, lowers manufacturing costs, and enhances economic efficiency.

Application and Advantages of Laser Cutting Machines for Metal Construction

Laser cutting machines are widely used in the construction industry, especially for processing steel structural systems such as bridges, high buildings, and steel-frame houses. They provide precise cutting of various metal pipes and sheets (such as steel, stainless steel, aluminum alloys, titanium alloys, etc.), ensuring high-precision fabrication of building components like doors, windows, stair railings, and guardrails, thereby enhancing the stability and safety of the structure.

The advantages of laser cutting lie in its exceptional cutting precision, ability to process complex shapes, compatibility with a variety of materials, and its ability to increase production efficiency. It also helps reduce material waste and costs, making it a highly effective solution for modern metal construction.

Benefits of Laser Cutting in the Construction

High Precision

Laser cutting machines deliver ultra-high precision cutting for a wide range of materials, including carbon steel, stainless steel, and aluminum alloys. This ensures adherence to the strict accuracy requirements of the construction industry, safeguarding the precision and safety of structural components.

High Speed

Compared to traditional processing methods, laser cutting machines operate with exceptional efficiency. Their cutting speed enables the completion of large volumes of tasks in a short time, significantly boosting productivity.

High Automation

Laser cutting machines typically feature a high degree of automation. Once parameters are set, the equipment can autonomously complete processing tasks. This not only enhances efficiency but also reduces labor costs.

Reduced Material Waste

With CNC systems, laser cutting machines can achieve automated and highly efficient material nesting and cutting. This optimizes material usage, minimizes waste, and significantly improves production efficiency and processing speeds.

Capability to Cut Complex Shapes

The flexible control of laser cutting systems allows for intricate and complex shapes to be cut, including sheet metal, pipes, and three-dimensional structures. This meets the personalized demands of architectural designs and brings more innovation to construction projects.

Diverse Cutting Capabilities

Equipped with various attachments, laser cutting machines can adapt to a wide range of complex metal shapes. Whether working on circular pipes, square pipes, oval pipes, or specialized profiles like H-beams and I-beams, they can handle flat cuts, bevel cuts, and drilling. Features like automatic feeding, intelligent clamping, precise rotation, and groove cutting further enhance their versatility.

Wide Material Compatibility

Beyond common metals, laser cutting technology can also process non-metal materials such as certain types of stone, glass, ceramics, and composites. This expands its application to architectural decoration and specialized engineering projects.

Application of Laser Cutting in the Construction Industry

1. Material Cutting

Metal Sheet: Laser cutting is widely used for processing metal structural components, particularly in handling heavy structural metal materials for large-scale buildings and complex bridges, such as steel beams, columns, and plates. Renowned for its speed, precision, and smooth cutting edges, laser cutting meets the stringent requirements of precision manufacturing, minimizes material waste, and significantly enhances efficiency and quality.

Precision Metal Components: In modern construction, precision metal components like handrails, guardrails, brackets, and fasteners require high-accuracy processing. Laser technology enables precise control of cutting paths and depths, ensuring exceptional quality in every detail.

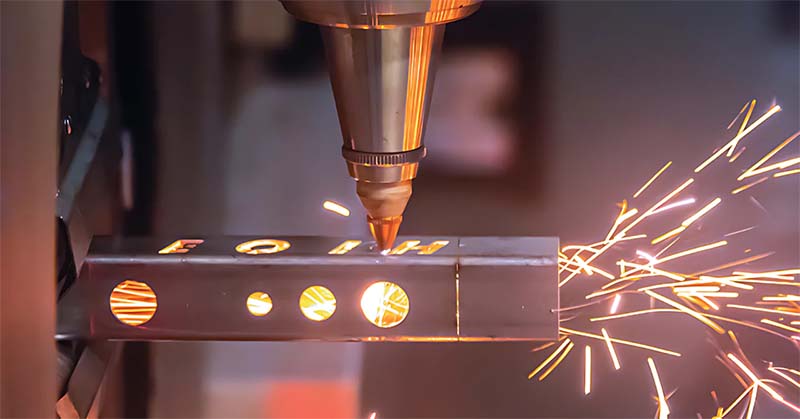

Metal Pipe: For metal pipes used in construction (e.g., water pipes, ventilation ducts, door and window guardrails), laser cutting facilitates efficient and precise cutting, hole-making, contouring, and pattern engraving. Whether for doors, windows, security screens, or railings, laser cutting ensures high-quality cuts and intricate designs while improving production efficiency and product accuracy, meeting diverse processing needs.

2. Fine Engraving and Marking

Laser technology is employed in the construction industry for intricate engraving and permanent marking. By precisely controlling laser energy and focus, it creates delicate patterns or text on various material surfaces, enhancing the aesthetic appeal and brand recognition of buildings.

3. Model Building and Prototype Design

Laser cutting plays a vital role in model building and prototype design due to its high precision, rapid processing, and broad material compatibility. It enables the swift creation of complex parts and intricate details, faithfully reproducing design concepts. With support for a variety of materials and flexible design adjustments, laser cutting significantly shortens development cycles and improves iteration efficiency, making it an ideal tool for realizing creative ideas and functional validation.

Limitations of Laser Cutting in Modern Construction

1. High Initial Investment and Maintenance Costs

The purchase cost of laser cutting machines is substantial, and they require regular maintenance and replacement of key components. This can pose a financial burden for construction companies with limited budgets.

2. High Technical Skill Requirements

Laser cutting machines must be operated by professionally trained personnel to ensure safety and efficient production. The need for skilled operator’s increases training costs and might limit accessibility for some companies.

3. Performance Limitations with Thick Materials

When processing ultra-thick metal plates or highly reflective materials like copper and aluminum, the efficiency and quality of laser cutting may fall short compared to alternative methods. This limits its applicability in certain construction projects requiring these materials.

Coil-Fed Laser Cutting Systems

Coil Fed Laser Cutting Machines offer a highly efficient and flexible solution designed for the production of metal structural components in various sizes and shapes. These systems feature robust uncoiling and coil-fed laser cutting capabilities with laser power options ranging from 1500W to 3000W. Operating at a maximum speed of 110m/min, they deliver a positioning accuracy of ±0.03mm/m and repositioning accuracy of ±0.03mm, ensuring high precision and efficiency in cutting operations.

Features:

Zero-Delay Cutting

Enables rapid cutting without waiting times, significantly enhancing production efficiency.

High Precision and Automation

Combines advanced laser technology with automated controls to ensure precise cuts and stable operations.

Flexible Cutting Configurations

Supports a variety of metal sheet sizes and shapes, easily adjustable to meet diverse production requirements.

Cost Reduction

Efficient production processes and automated operations reduce material waste and labor costs effectively.

High Power Sheet Metal Laser Cutting Machine

High Speed and Precision

Equipped with an imported servo system drive, imported transmission system, and linear guide rail guidance, this machine ensures exceptional operational speed and cutting precision, significantly enhancing production efficiency.

High Accuracy and Stability

Utilizing a custom-built large gantry machine, the geometric accuracy of the machine is controlled within 0.03mm, ensuring stable and accurate operation.

Automatic Focus Adjustment

The laser head features an automatic focus adjustment capability, reducing piercing time by 80% compared to traditional cutting heads, which greatly shortens processing cycles.

Efficient Profile Switching

The cutting head employs a parabolic motion mode for cutting different profiles. It can perform “leapfrog” actions automatically during profile transitions, further improving cutting efficiency.

Professional Software Support

Integrated with specialized laser cutting software, the machine offers features such as graphic nesting and sharp corner smoothing, facilitating fast cutting while reducing material waste.

Applications

Sheet Metal CNC Laser Cutting Machines are primarily used for the rapid cutting of sheet metals, including but not limited to carbon steel, silicon steel, stainless steel, aluminum alloys, titanium alloys, galvanized sheets, iron, and copper. Their ability to efficiently process a variety of metal materials while maintaining high cutting quality and speed has made them indispensable in industries such as metal manufacturing and construction.

Choosing the Best CNC Laser Cutter for Building Materials Industry

Investing in a laser cutting machine can bring tremendous benefits to your construction business. With features like high precision, fast speed, versatile functionality, and cost savings, our laser cutters are invaluable tools for manufacturing high-quality and efficient metal components used in construction and infrastructure projects. By enabling quick and accurate cutting of various metals, laser cutting machines help reduce waste and enhance productivity, saving both time and money for yours businesses.

The DPLASER laser cutting machines for construction industry ensures precise cutting of metal sheets and pipes, even in complex environments, making it a one-stop solution for your cutting needs. If you’re purchasing for the first time and are unsure which laser cutting equipment suits you best, our laser cutting experts are here to assist. They can help identify your requirements and recommend the machine that meets your specific needs.